Low-cost, High Production Efficiency PCB Materials

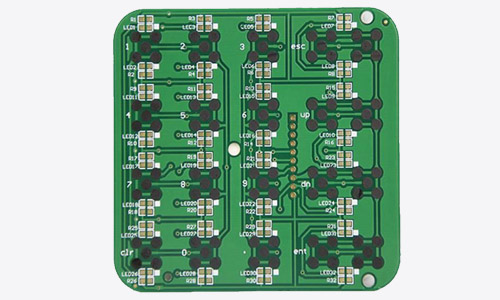

What Is Carbon Ink PCB

Carbon Ink PCB is a special type of printed circuit board which printed with carbon ink. Compared to traditional copper foil circuits, carbon Ink PCBs have poor conductivity, low power transfer capability and limitations on high-frequency signals, etc. However, carbon ink PCBs have a wide range of applications in the field of flexible electronics, particularly in applications that prioritize cost-effectiveness, flexibility and environmental protection.

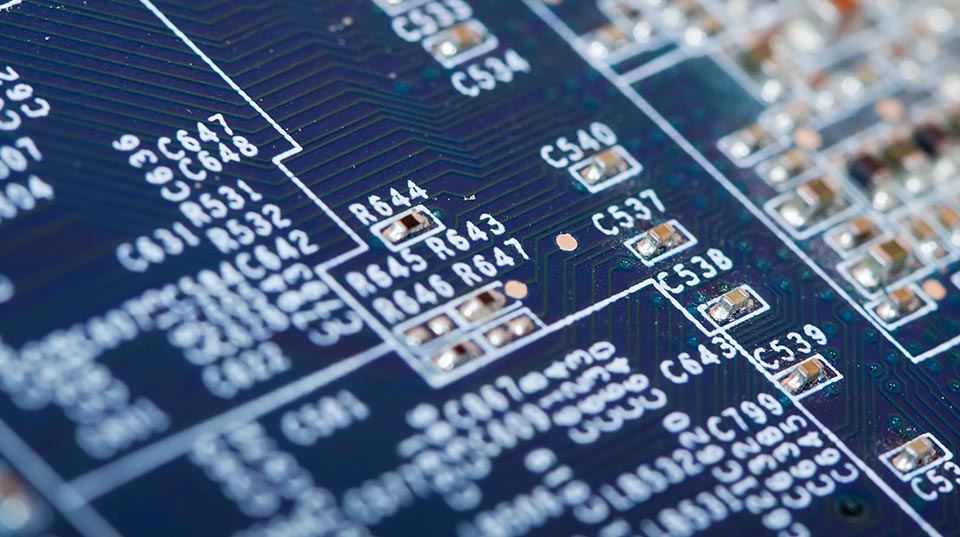

Simple Process, Extending The Life of Circuit Board

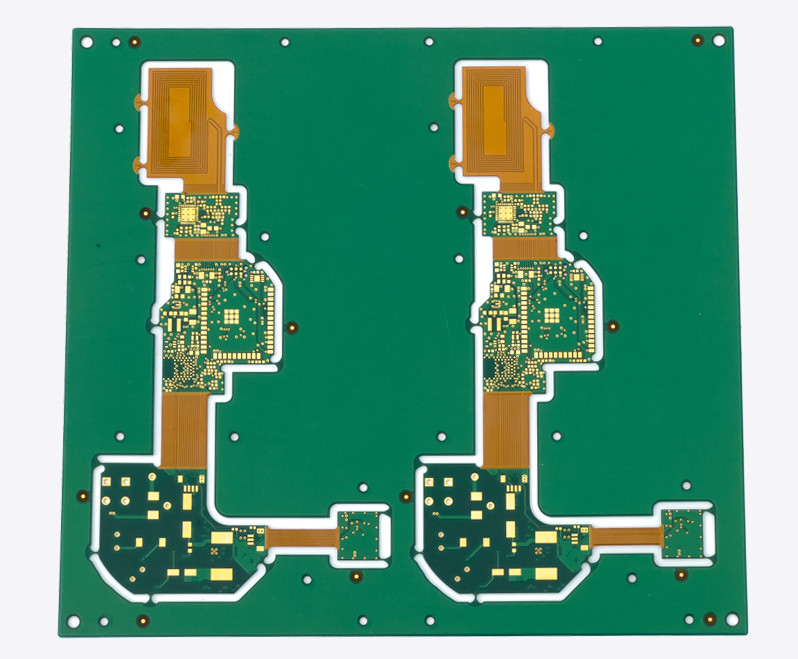

- Flexible: Carbon ink PCB can flexibly adapt to bending, folding and irregular shapes, making it especially suitable for applications that require flexible circuit boards, such as wearable devices, sensors and flexible electronic products.

- Low cost: Carbon slurry material cost is low, printed circuit board production is simple, economical and efficient.

- Environmental protection: The carbon ink materials used in carbon ink PCBs are typically non-toxic, harmless, and biodegradable, which by ecological protection requirements.

- Electromagnetic shielding: The carbon ink layer has good electromagnetic shielding performance, which can effectively reduce electromagnetic interference and crosstalk.

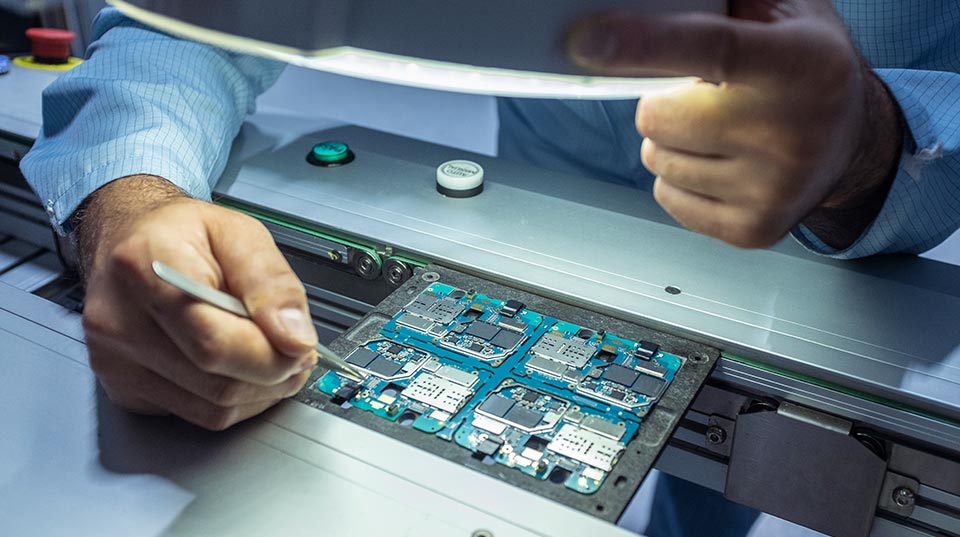

SCSPCBA produces carbon ink PCBs for flexible electronic products, sensors, wearables, etc. And our cost-effective advantage makes us stand out in PCB manufacturing. About the cost and technical details, please feel free to contact us.