High-reliability Circuit Board With Edge Plating Technology

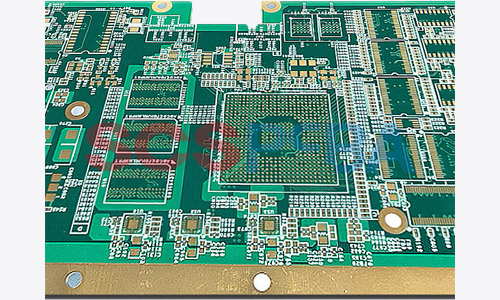

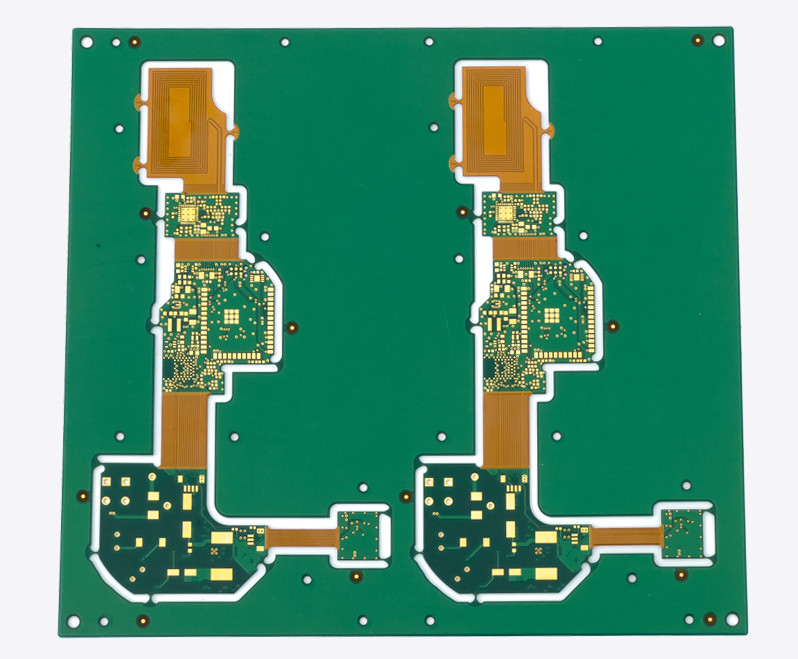

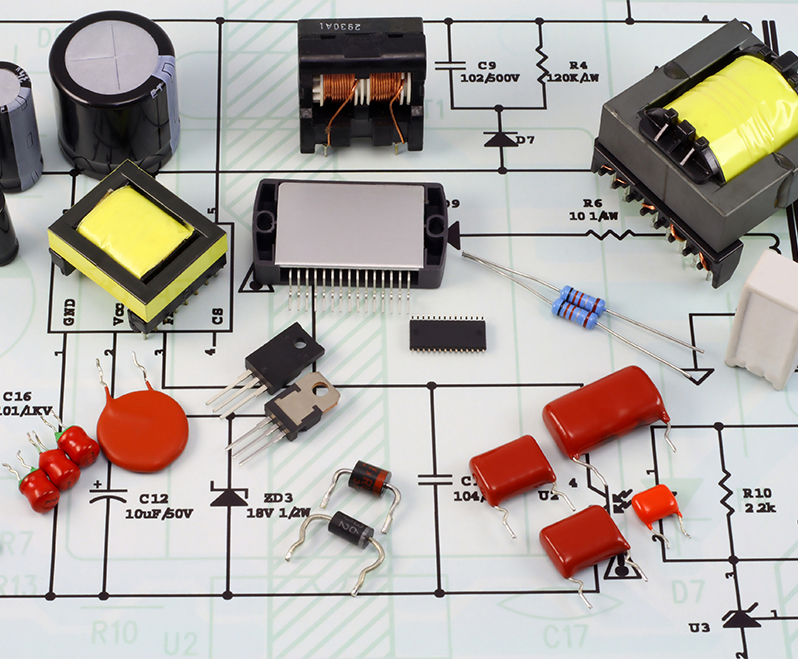

What Is Edge Plating PCB

The manufacturing process of edge copper plated PCB involves exposing the edge portion of the PCB and coating it with thin copper.

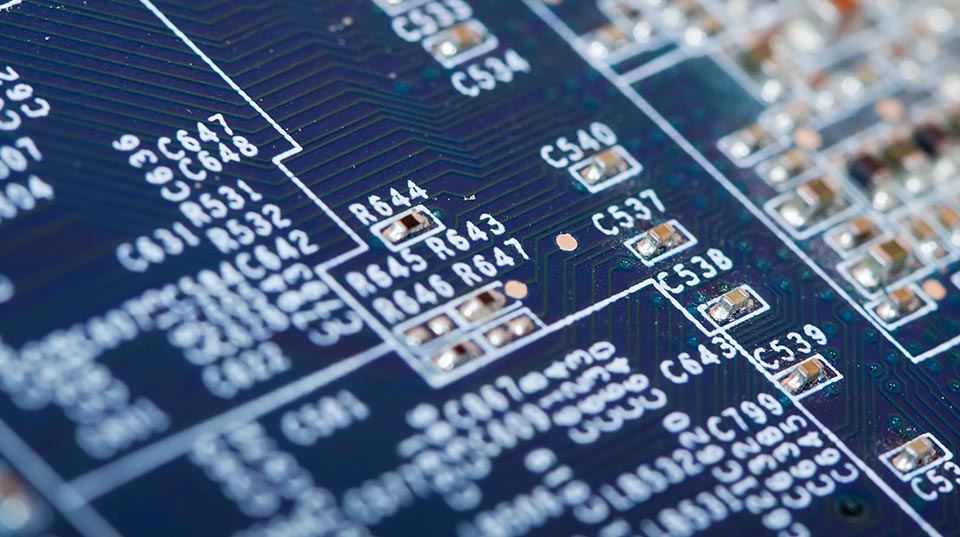

Widely Compatible Design, Adapt to Multiple Devices

- Mechanical strength: Edge copper plating increases the mechanical strength of the PCB edge, making it more durable and resistant to bending.

- EMI/RFI shielding: By adding edge copper which can provide better electromagnetic interference (EMI) and radio frequency interference (RFI) shielding effect, reducing mutual interference between circuits.

- Connection reliability: Edge copper plating provides a more reliable connection, especially in applications that require plug-in connectors or edge connections, which can provide better electrical connection performance.

- Protective performance: The copper-plated edge provides additional protection to prevent the PCB edge from being affected by mechanical damage or environmental factors.

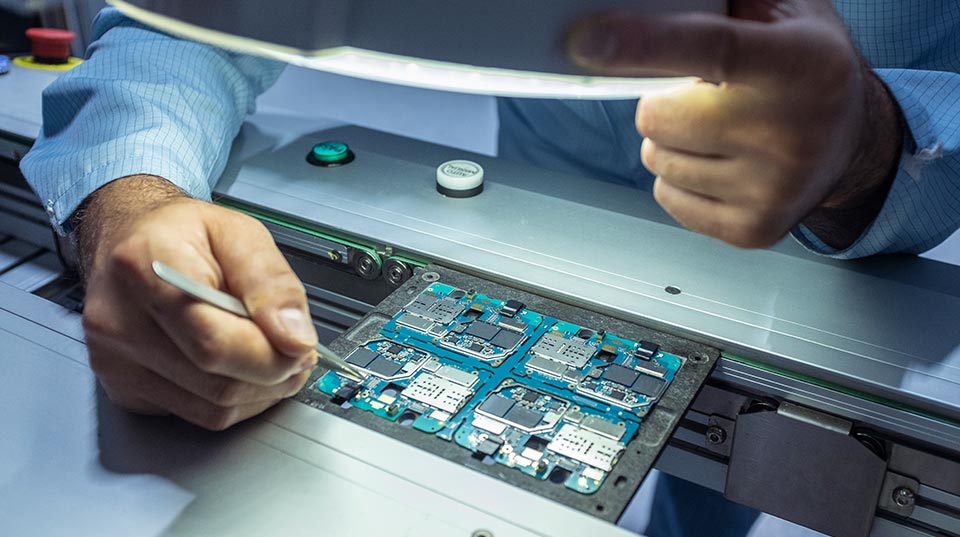

SCSPCBA has its own PCB factories with advanced equipment and technology, which can provide high-quality and reliable edge copper-plated PCB manufacturing services.