Ensure Peak PCB Assembly Performance with Precision Functional Testing

PCBA Manufacturing Experts You Can Rely On

- Innovative PCBA manufacturing

- On-time PCB assembly, every time

- Comprehensive functional testing services

- Cost-effective PCB assembly manufacturing

- Unlock integrated circuit assembly fast quotation reliability

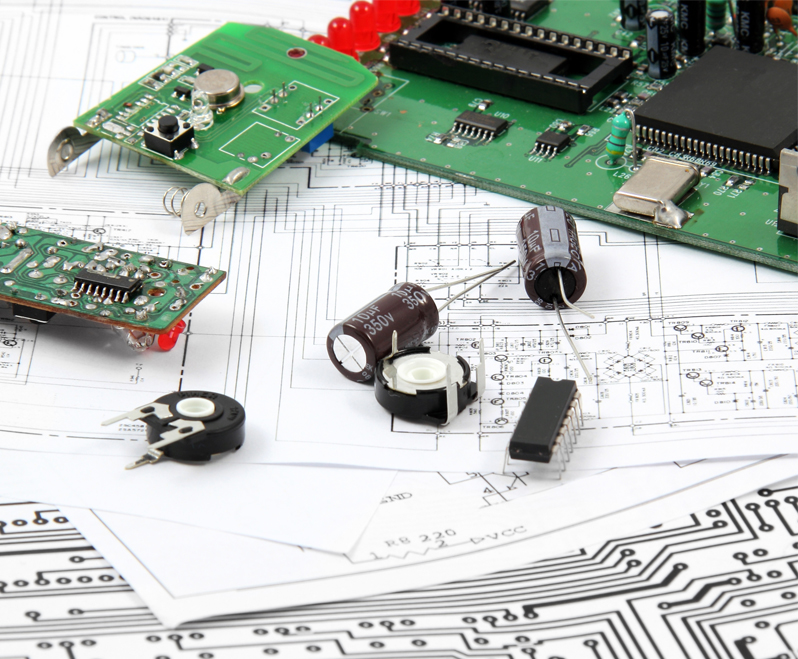

Boost PCB Assy Reliability with Functional Testing

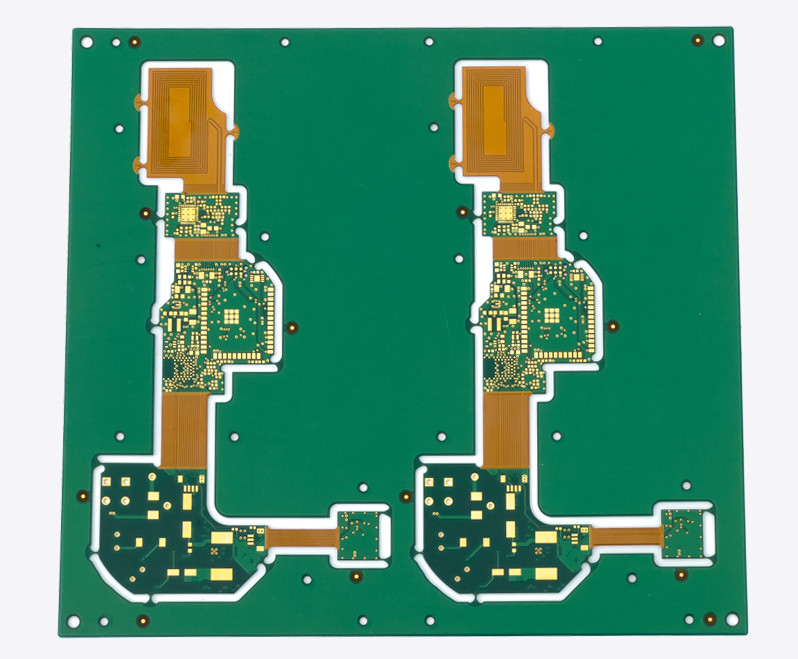

As a leading one-stop AI intelligent PCBA manufacturer, SCSPCBA specializes in turnkey PCB assembly solutions. We offer comprehensive PCBA functional testing services to ensure the highest quality and reliability of your printed circuit board assemblies. PCB assembly functional testing is the most thorough and critical test performed to evaluate the final performance of a PCB after assembly. It determines the pass/fail status of each board by simulating real-world conditions and checking for potential issues. This ensures circuit boards meet strict quality standards and perform flawlessly.

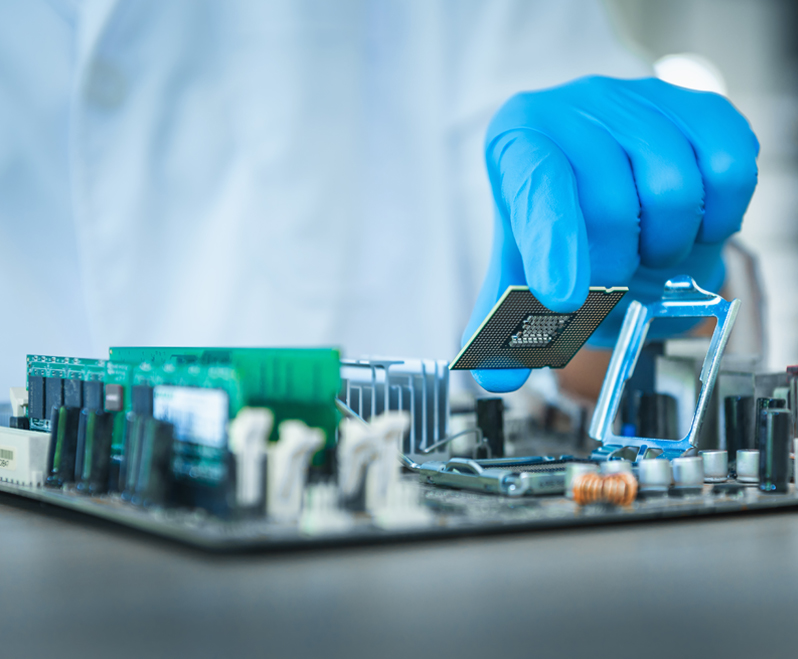

PCB Assembly Functional Testing Steps

- Test Preparation

Before conducting electronic assembly manufacturing functional test, it is necessary to prepare test equipment, test tools, test procedures and test environment, etc.Avoid inaccurate test results due to test environment problems.

- Test Program Writing

According to the circuit board design specifications and printed circuit board assembly functional requirements, write the corresponding test program. The test program is usually written by SCSPCBA professional test engineers according to the test needs and test purposes, and is used to test whether the PCB board production functions are normal.

- Test Execution

Execute the test program and record the test results. If the test results meet the requirements, the circuit card assembly can be considered a qualified product; otherwise, it needs to be repaired or remade.

- Test Record

Record the test results and compare the test results with the design specifications to confirm whether the circuit board meets the requirements.

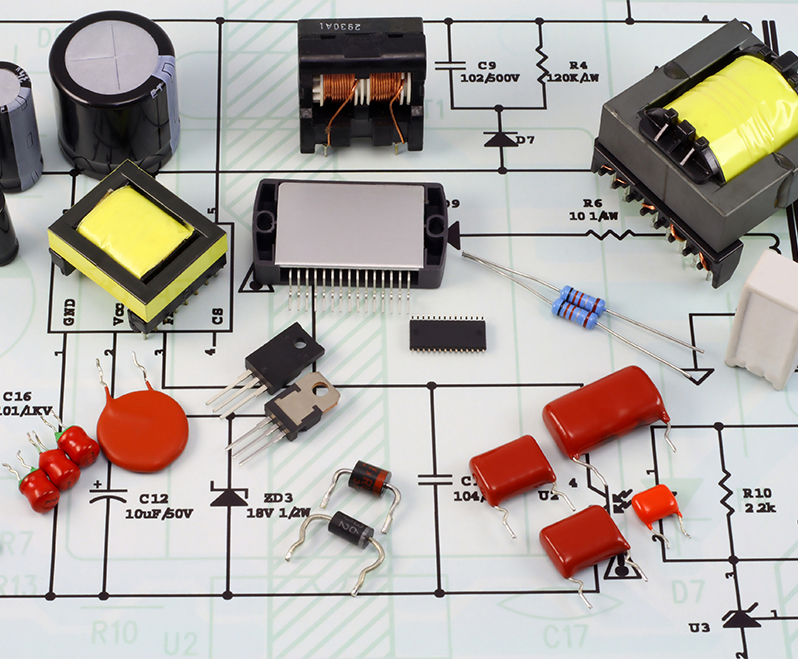

Special Equipment Used In PCBA Functional Testing

SCSPCBA according to PCB assembly manufacturing process, the functional and test requirements are different, which will use different test equipment in the functional test.

- Multipurpose Digital Meter

It is used to test the voltage, current, resistance and other parameters of circuit boards.

- Oscilloscope

It is used to observe and analyze the signal waveform of circuit boards and can detect the frequency, amplitude, phase, and other information of the PCB board’s signal.

- Logic Analyzer

It is used to test digital circuits, and can analyze the status and transmission information of digital signals.

- Spectrum Analyzer

It tests the frequency response and spectrum characteristics of circuit board manufacturing and can detect the signal spectrum, bandwidth, peak value, and other information.

- Analog Signal Generator

It is used to generate various analog signals, such as sine wave, square wave, triangle wave, etc., to test the response characteristics of the circuit.

- Signal Generator

It is used to generate various digital signals, such as pulses, high and low levels, etc., to test the response characteristics of digital circuits.

- Power Supplier

Used to provide the DC or AC power required by the circuit.

- Test Fixture

Used for fixing PCB and assembly, connecting test instruments and collecting test data, etc.

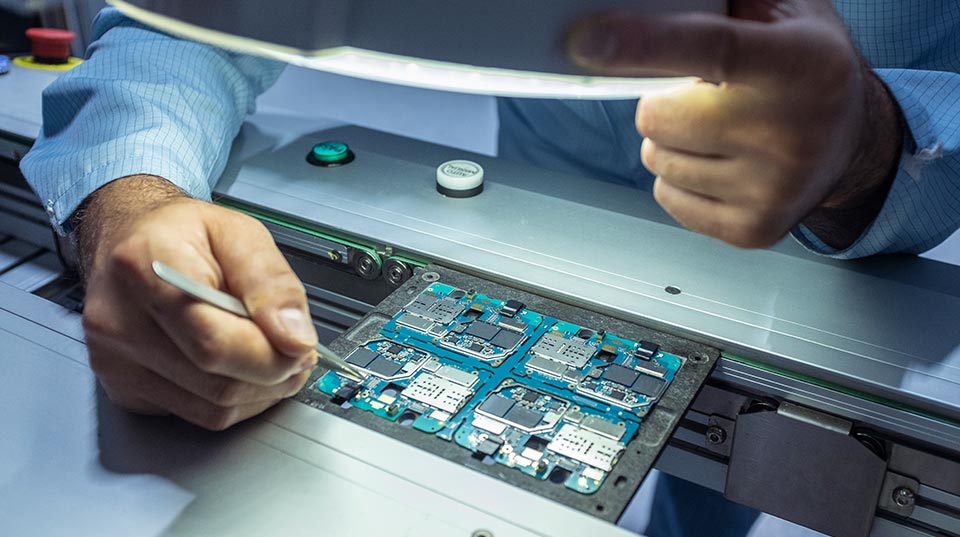

Special Tool For PCBA Functional Test – Fixture

The functional test fixture is a special tool for printed circuit board production functional tests, used for fixing PCB printed circuit board, connecting test instruments, collecting test data, etc.

- Fixture Positioning

The fixture needs to be able to accurately position the PCB board to ensure the consistency of the position and posture of the PCBA during testing.

- Test Interface

The fixture must provide an interface connected to the test instrument to perform electrical performance tests or signal tests on the printable circuit boards.

- Data Acquisition

The fixture needs to provide a data acquisition interface to collect test data and perform data analysis and processing.

- Communication Interface

The fixture must provide a communication interface to transmit the test results to the host computer or data center for data processing and analysis.

- Reusable

The fixture needs to be reusable to maintain the consistency and stability of the test results in multiple PCBA functional tests.

SCSPCBA provides one-stop PCBA manufacturing services, you only need a phone call or email to get the perfect solution, from engineering design to circuit board manufacturing, to assembly and testing, we can provide perfect solutions.