High-precision Gold Plating Technology Promotes Innovation

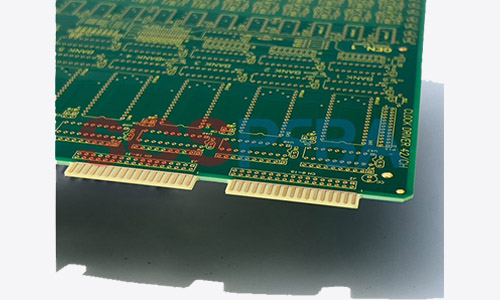

What Is Gold Fingers PCB

Gold fingers are typically located on the edge of the circuit board, and they are designed and arranged in specific shapes and patterns to facilitate connection with other devices or plug-ins.

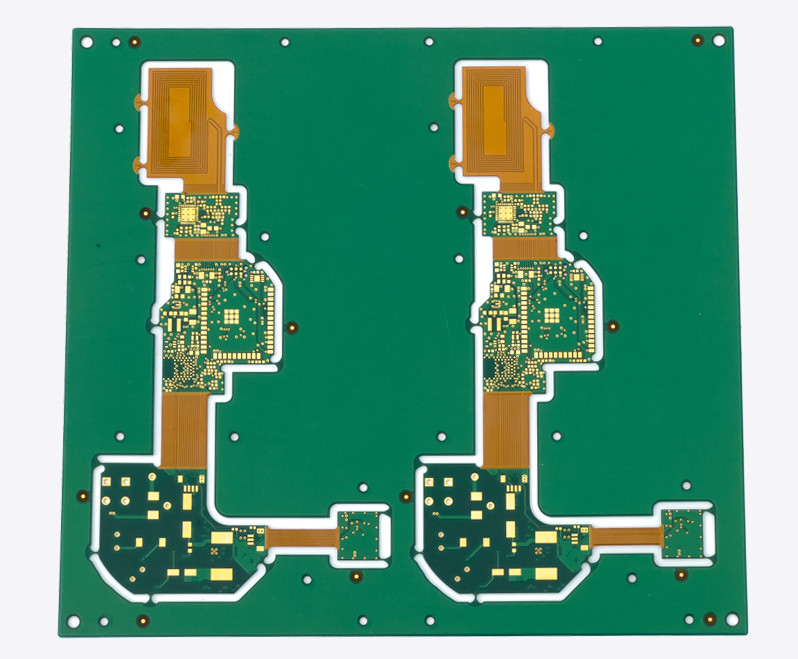

Gold-plated Finger Design, Improve Connectivity

- High-reliability connection: Gold is an excellent conductive material with exceptional electrical conductivity and corrosion resistance. By using gold material on the gold fingers, a reliable electrical connection can be achieved and provide lower resistance and better signal transmission quality.

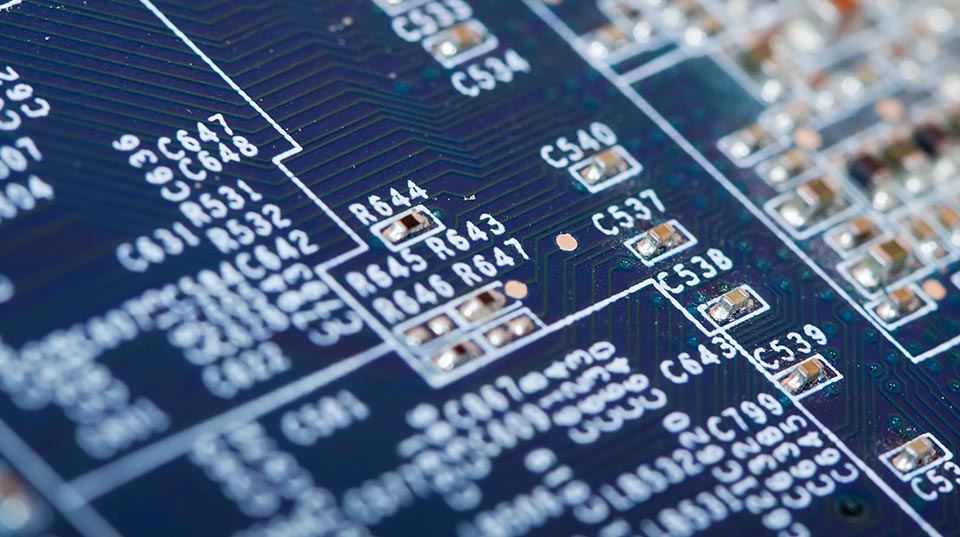

- Gold plating protection: Gold fingers are typically electroplated to evenly cover the connector with metal material. This electroplated gold layer not only provides better electrical conductivity but also protects the connector from oxidation, corrosion and abrasion, thereby extending its lifespan.

- Easy to plug and pull: Hard gold fingers have smooth surfaces and excellent abrasion resistance, making the plug and pull operations with other devices or plug-ins smoother and more reliable. Gold finger connectors are suitable for applications that require frequent plug and pull, such as expansion cards, slots, sockets, etc.

- Signal integrity: The metal material of the gold finger has low resistance and capacitance which can reduce signal loss and interference, providing better signal integrity. This is particularly important for high-frequency and high-speed transmission circuits.

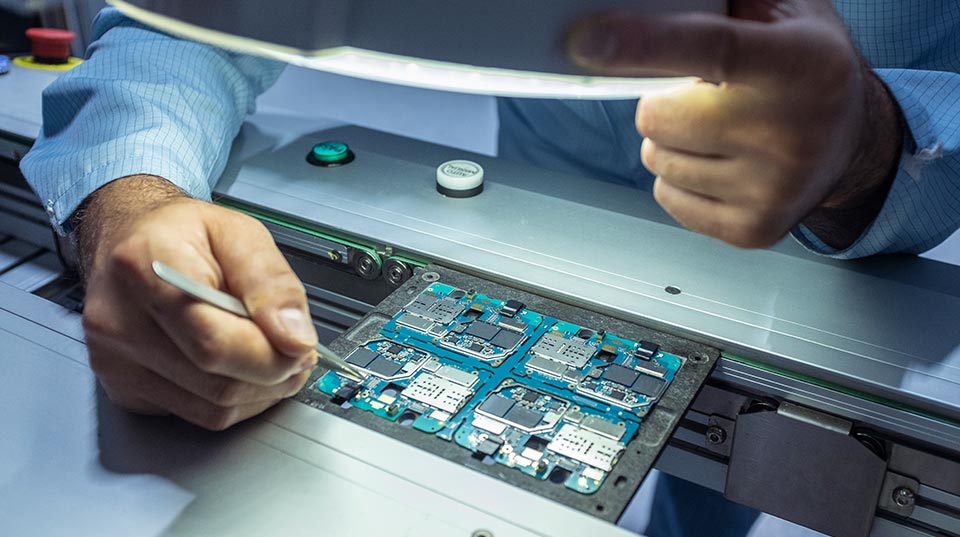

SCSPCBA has produced many golden finger boards for servers, industrial control, high-performance computers and communication equipment, etc.