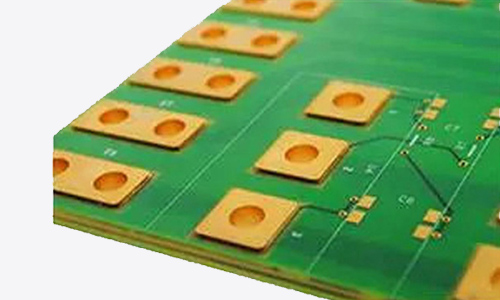

Thick Copper Circuit Board, Improve Current Carrying

What Is Heavy Copper PCB

Heavy copper PCB is made on traditional FR4 substrate by increasing the copper thickness to achieve high current and power transfer and to provide better heat dissipation.

The Advantages of Heavy Copper PCB Include

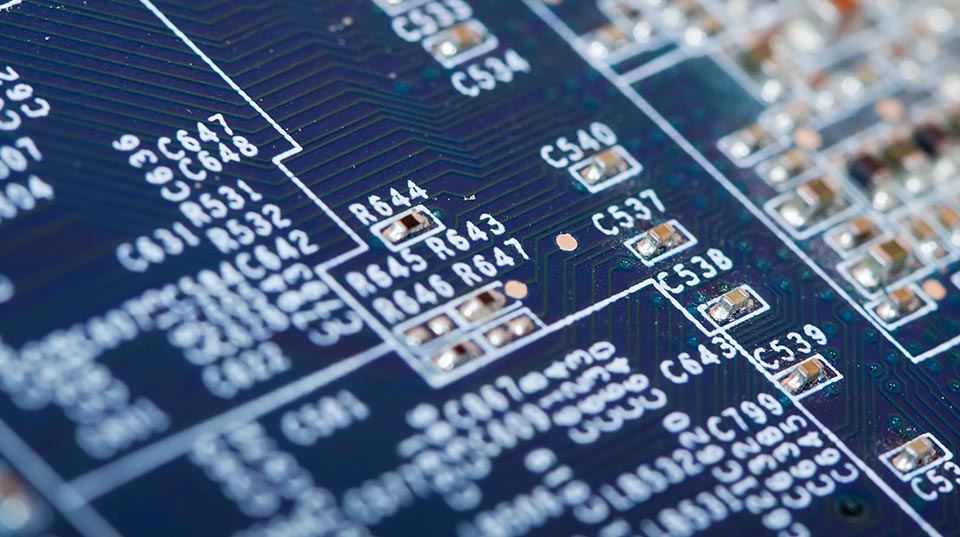

- High current transmission: Heavy copper PCB can withstand high current transfer due to the increased thickness of copper. It is suitable for applications that need to handle high-power circuits and high currents, such as power electronics, electric vehicle chargers, and industrial devices.

- Excellent thermal management: Thicker copper has better performance in conducting heat. Heavy copper PCB can effectively disperse and conduct heat, providing better heat dissipation and thus protecting circuit components from overheating.

- Improve mechanical strength: Thick copper foil increases the mechanical strength and stability of PCB. Heavy copper PCB has better resistance to vibration, shock, and environmental stress for applications requiring high reliability and durability.

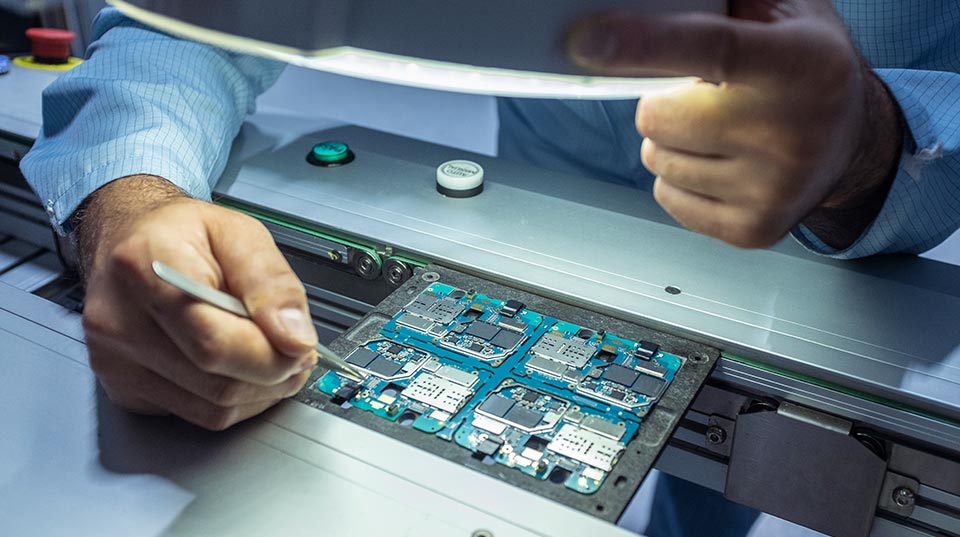

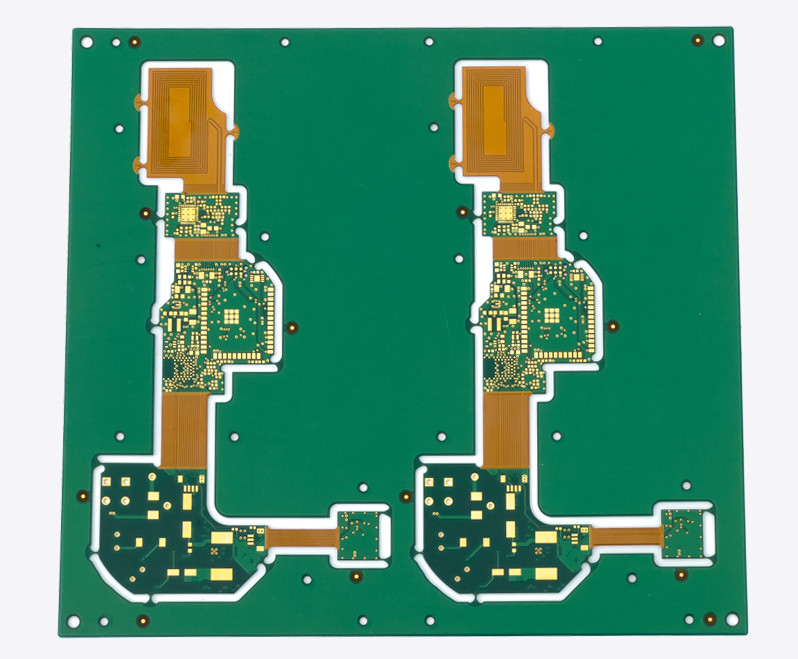

- Support multi-layer design: Heavy copper PCB can be used in conjunction with multi-layer designs to meet the needs of complex circuit layouts and high-density wiring. Multi-layer PCB board designs also provide greater design flexibility and freedom.

- High reliability: Due to better thermal management and mechanical resistance, it provides higher reliability and long lifespan. It’s important for critical applications and industries that require high reliability, such as aerospace, military and medical equipment.