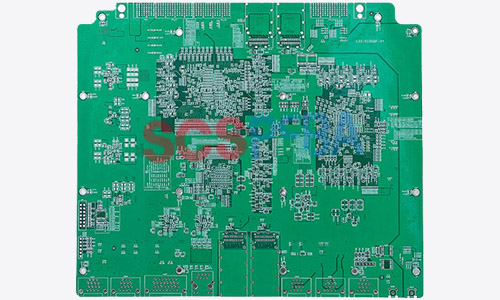

High-end Circuit Boards with Precise Control of Signal Integrity

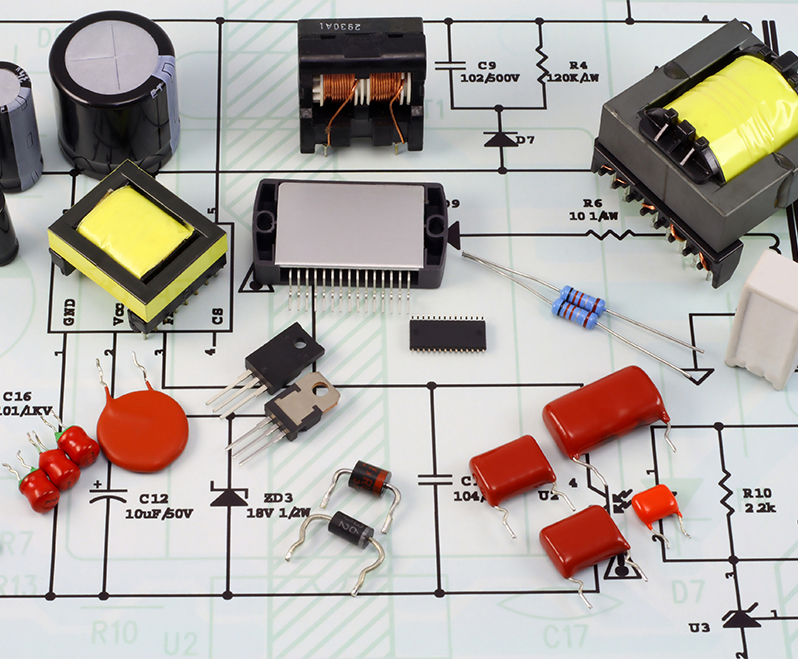

What Is Impedance Controlled PCB

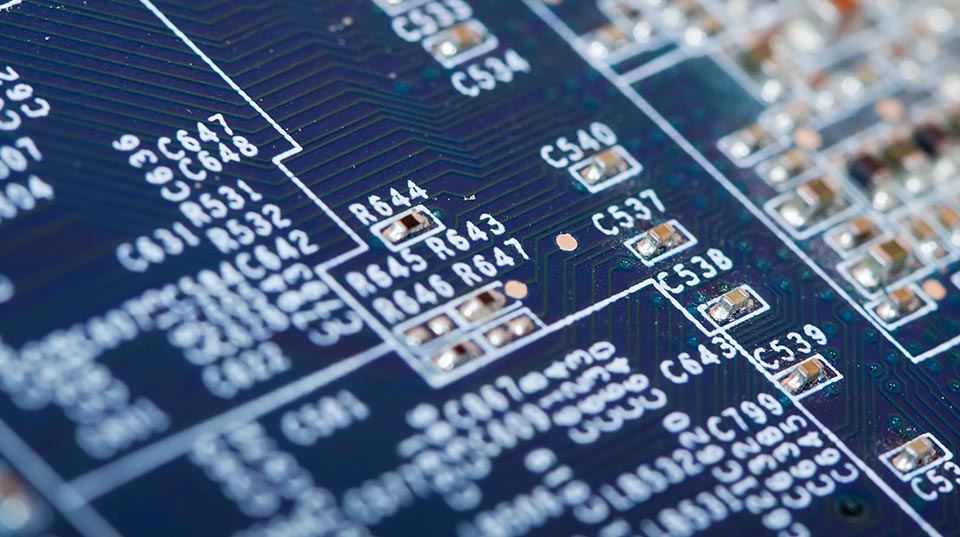

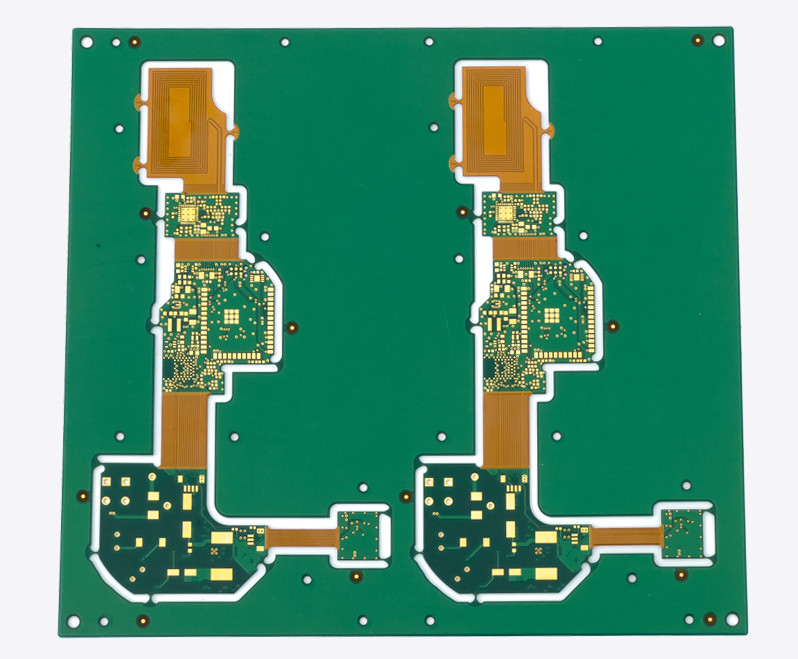

Impedance controlled PCB must consider material, layer stack-up, accurate line width and spacing, dielectric constant, etc. Impedance is the ratio between current and voltage, and it’s one of the key parameters for signal transmission in a circuit. Maintaining accurate impedance matching is crucial for signal integrity and performance, especially in high-frequency and high-speed circuits.

Precise Impedance Circuit Board Manufacturing

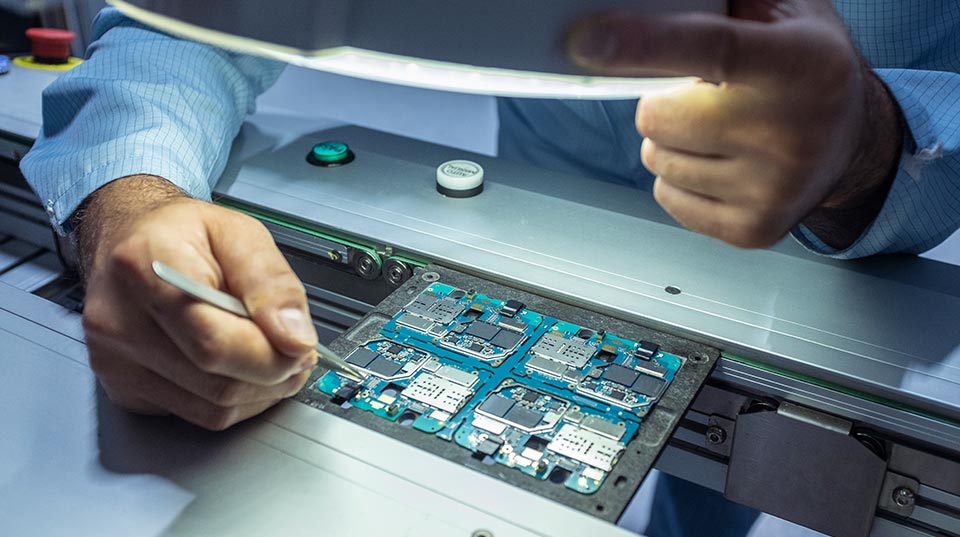

- Design verification: Our engineering team will carefully review and verify the customer’s circuit design files to ensure that the impedance control requirements are consistent with the customer’s design goals.

- Material selection: We will select a specific substrate material that meets impedance requirements, and ensure the material has stable dielectric constant and impedance characteristics.

- Manufacturing process: We will use a precise manufacturing process to ensure the accuracy and consistency of impedance values by control line width, spacing, layer spacing and dielectric constant, etc.

- Testing and validation: After PCB board production is finished, we will do testing and verification to ensure that the impedance value of each circuit board meets the design requirements.

SCSPCBA focuses on quality control and process control to ensure that the produced impedance controlled PCBs have stable performance and consistent impedance values. You can rely on SCSPCBA’s professional capability and experience to obtain high-performance impedance circuit board.