Maximize Device Lifespan with Professional Printed Circuit Assembly Repair

Help You Complete Your Project Faster And Better!

- ISO9001 & UL Certified

- Experience hassle-free PCBA solutions

- SCSPCBA profession PCB manufacturing repair teams

- Assy PCB repair and maintenance services you can count on

- Expert-assembled circuit board repair services for quick turnaround

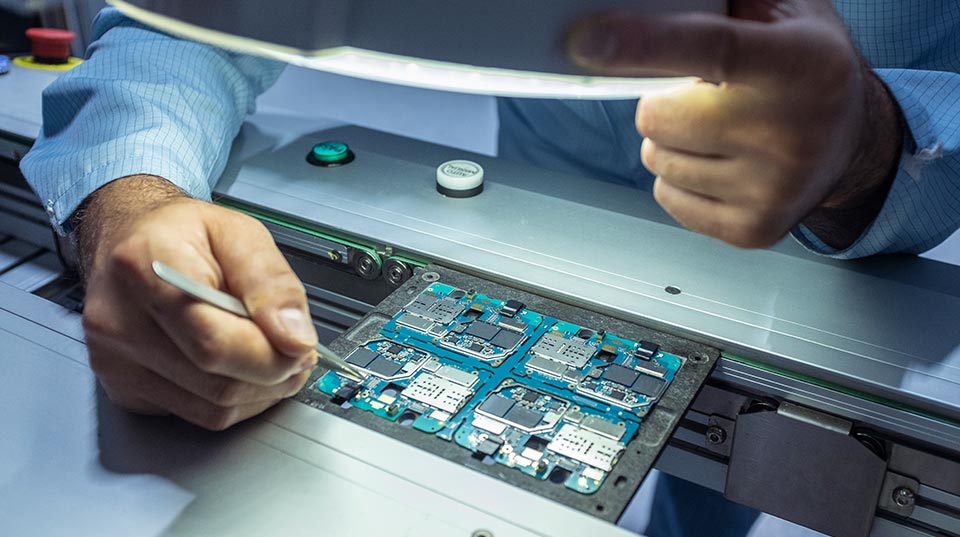

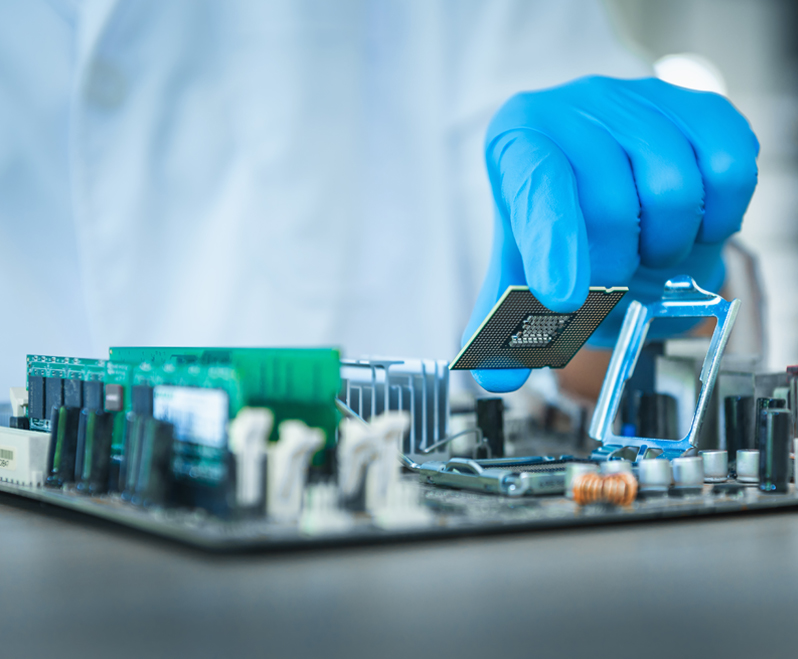

Circuit Board Repairing

SCSPCBA has complete SMT machine and a professional technical team, that can provide printed circuit board repair services.

The operation follow-up of the entire PCB board manufacturing process and professional circuit board repair personnel capable of addressing various PCBA failures ensure electronic assembly quality stability.

SCSPCBA: Essential Tools and Materials for Effective PCBA Repair and Maintenance

- Soldering Tools for PCB Repairs

Includes soldering iron, solder wire, solder paste, and other essential tools for precise component joining and repairing PCB assembly connectors. Ideal for PCBA welding repair and electronic circuit board fixes.

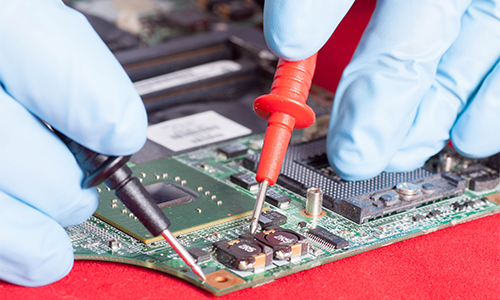

- PCBA Testing Tools

Multimeters and oscilloscopes are crucial for testing pcb and assembly connectivity and checking voltage, current, and resistance. These tools help verify circuit board performance and ensure proper functionality during PCBA troubleshooting.

- Printed Circuit Repair Toolbox for Electronics Assembly

Essential tools include pliers, tweezers, wrenches, and more for the removal and adjustment of printed circuit assembly components. A well-stocked toolbox ensures efficient PCB maintenance and repair tasks are carried out precisely.

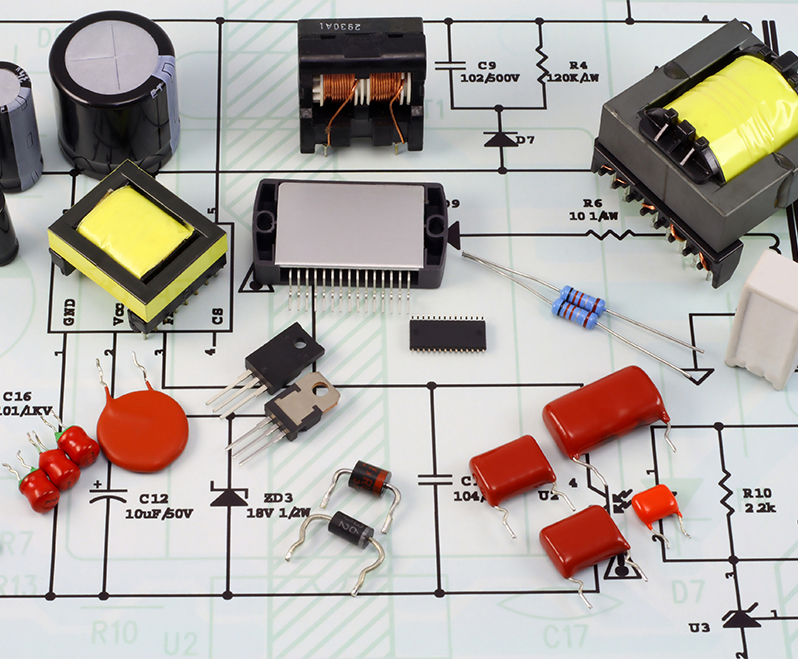

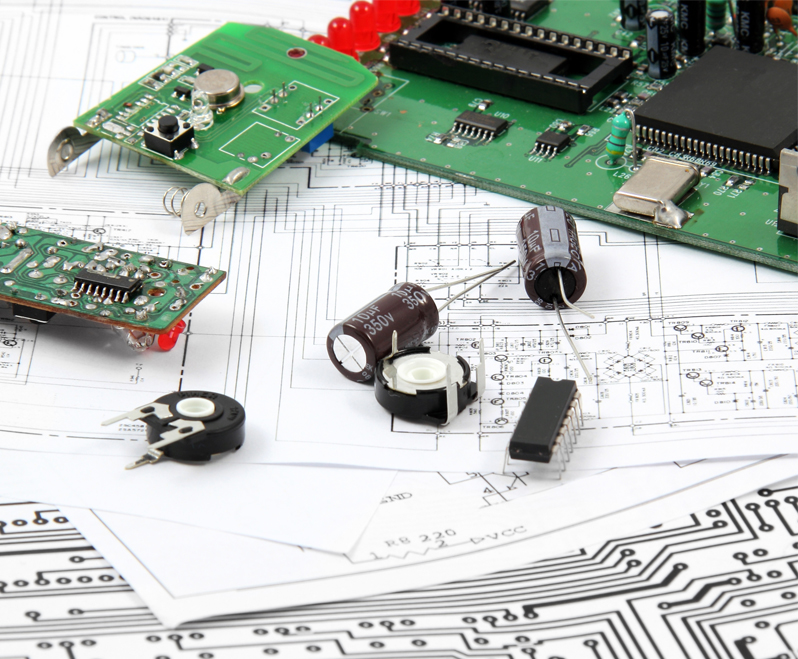

- Replacement Electronic Components for PCB Assembly

Ensure your repairs are reliable by having common electronic components for PCB replacement like capacitors, resistors, diodes, and transistors. Stocking up on these components is crucial for PCBA component replacement and electronic repairs.

- Electronic Board Repair and Maintenance Documentation

Incorporating PCB wiring diagrams, circuit schematics, and component datasheets into your workflow allows for accurate component placement and effective PCB troubleshooting. These resources are essential for PCBA maintenance and ensuring high-quality repairs.

- PCB Cleaning Supplies for Post-Repair Work

Use cleaning cotton, PCB cleaning alcohol, and other cleaning agents to remove solder flux residue and dirt from the board after repairs. This ensures the cleanliness and reliability of the PCB boards and prevents potential damage during PCBA rework.

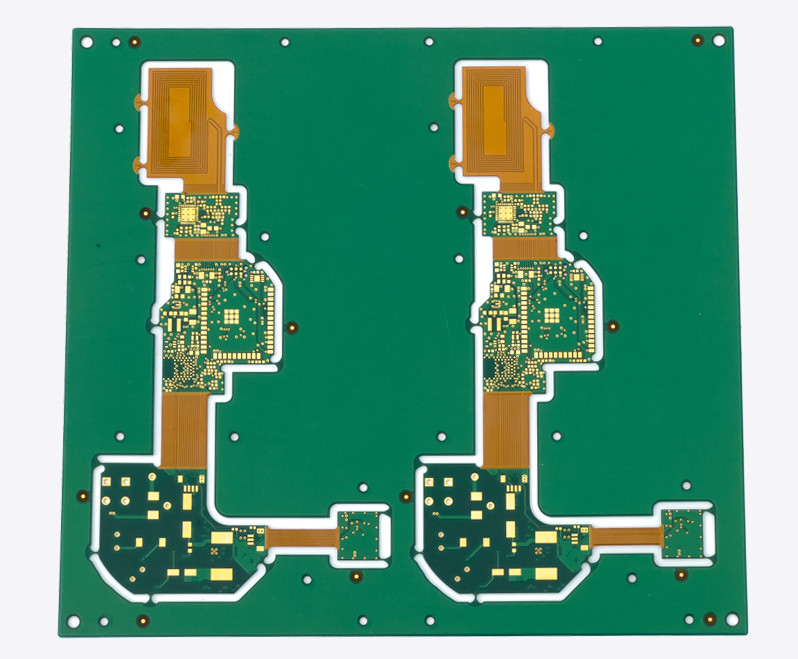

Your Go-To Source for High-Quality Circuit Board

SCSPCBA analyzes the PCB assembly failures issue through several key aspects to ensure efficient repair and recovery:

- Visual PCB Board Assembly Inspection

Start by visually inspecting the PCB board to identify visible issues like burnt areas, oxidation, cracks, or damaged electronic parts. Check connectors, capacitors, resistors, and diodes for physical damage that could affect performance.

- Electronics Components Testing

Use multimeters, oscilloscopes, and signal generators to test whether components like capacitors, resistors, and transistors function correctly. Aging or electromagnetic interference can cause PCB board parts failure, leading to poor circuit performance.

- Signal Detection for Electronic Assembly Troubleshooting

Use an oscilloscope to detect whether signal transmission is normal. Inspect for issues like loose connectors, poor solder joints, or broken traces that can cause signal loss, resulting in circuit failures.

- Thermal Imaging for PCBA Heat Troubleshooting

Utilize a thermal imager to identify overheated components on the printed board. Poor heat dissipation or an inefficient circuit design can lead to excessive heat and component failure. Thermal hotspots often indicate underlying issues that need to be addressed.

- Hardware Debugging for Circuit Analysis

Perform hardware debugging by injecting signals into specific points of the circuit and analyzing the reaction to identify fault locations.

- Software Debugging

Check for software-related failures during program debugging. Ensure that the program is correctly loaded and the peripherals are properly detected. Software errors can often cause PCB assembly and manufacturing failure when data processing is incorrect.

- Fault Simulation for PCB Assembly Failure Analysis

By mimicking real-world conditions, fault simulation helps uncover potential failure points, improving troubleshooting accuracy.

- PCBA Programming Issues and Circuit Failure

For assembled circuit boards requiring programming, ensure that the chip is correctly programmed. Programming errors or faulty chips can lead to malfunctioning circuits, causing widespread issues across the board.

PCB Assembly Maintenance Process

Always handle circuit board repair service with care to prevent further damage. For guidance, consult professional PCBA engineers from SCSPCBA for expert assistance.

- Diagnose PCB Board Production Failure

Identify circuit board failure symptoms and determine the root cause of the issue for effective repair.

- Disassemble and Clean

Carefully remove PCBA board from equipment and clean it to ensure thorough inspection and circuit assembly maintenance.

- Replace Faulty Components

Identify faulty electronic component assemblies and use the right tools to remove and replace them. Prepare replacement electronic parts such as capacitors, resistors, and ICs.

- Soldering Components

Use appropriate soldering tools to mount new PCB components onto the circuit board, ensuring strong solder joints for long-term performance.

- Reprogram the Board

Reprogram the printed circuit board assembly by downloading the correct firmware or software for optimal functionality.

- Test the PCBA

Test the repaired PCB to ensure it’s functioning correctly and meeting specifications.

- Final Cleaning and Organization

Clean up any solder flux or dirt, and organize the surface mount component for a neat, professional finish.

- Acceptance and Delivery

Final inspection to confirm the printed circuit board assembly repair is complete and functional, followed by delivery to the customer.