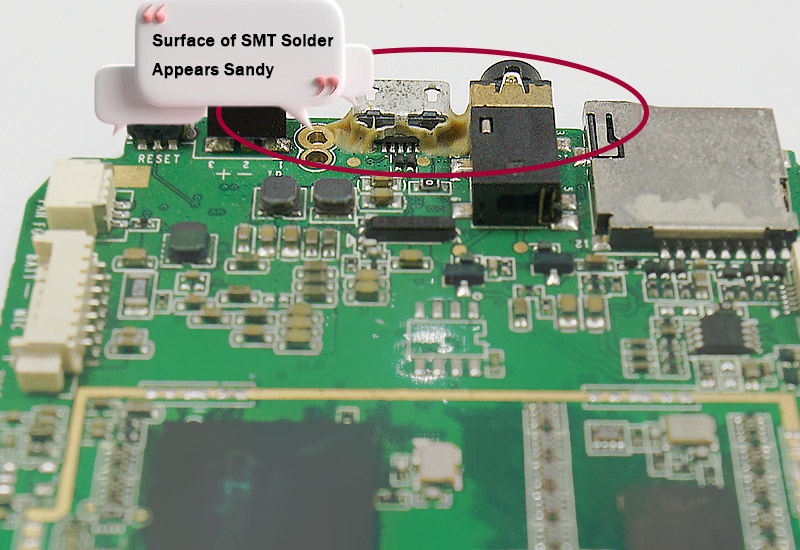

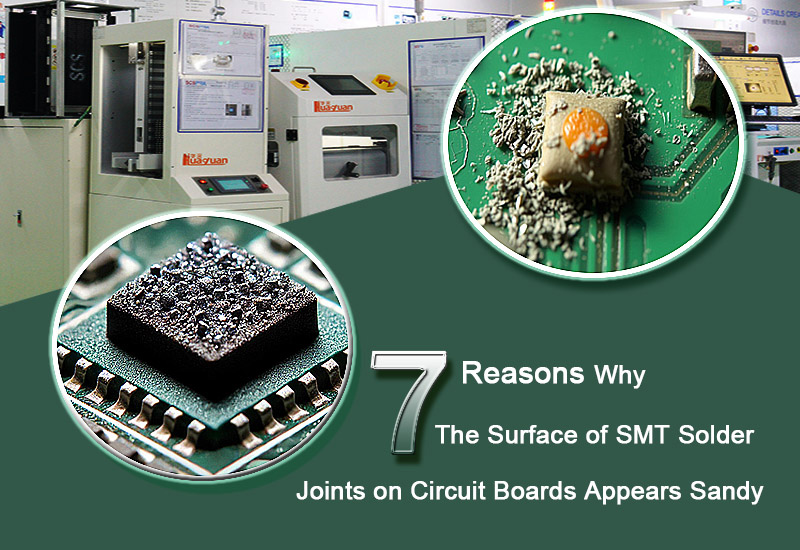

7 Reasons Why The Surface of SMT Solder Joints on Circuit Boards Appears Sandy

The Following Reasons May cause the Sandy Feeling on The Surface of SMT Mounting Solder Joints:

1. Solder Paste Problem

The metal particles in the solder paste are too large, an inappropriate type is used, or the quality of the solder paste is poor. The solder paste may also absorb moisture when exposed to the air for a long time, making the solder joint surface uneven.

2. Expired Solder Paste

The active agent components of the flux in the solder paste chemically erode the surface of the tin powder, causing “oxides” to form on the surface of the tin powder. This “chemical corrosion” reaction not only changes the melting characteristics of the tin powder but also consumes the active components in the flux, making it difficult to effectively and thoroughly remove the oxides on the surface of the tin powder during reflow soldering. The solder joints where the tin powders are not fully melted will have a dull sandy appearance.

3. Soldering Temperature Is Too High or Too Low

If the printed circuit assembly soldering temperature is too high, the solder will oxidize quickly, resulting in a rough solder joint surface. If the temperature is too low, the solder will not melt completely, and the solder joint surface will also appear rough.

4. Improper Welding Time

PCB manufacturing welding time that is too short or too long will affect the quality of the solder joint. Too short a time may result in the solder not being completely melted, while too long a time may result in solder joint oxidation and welding defects.

5. Poor Atmosphere in The Reflow Oven

If the nitrogen protection in the reflow oven is insufficient or the oxygen content is too high, the circuit board solder joint surface may oxidize, resulting in a gritty feel.

6. Contamination of Substrate or Components

Oxide layer, dirt or grease on the substrate surface or component pins may also cause uneven circuits on board solder joint surface.

7. Improper Cooling Speed

Excessive cooling speed may cause the grain structure of the solder joint surface to be rough, thus showing a sandy feel. It is recommended to control the cooling rate according to the printed circuit board manufacturing process requirements.