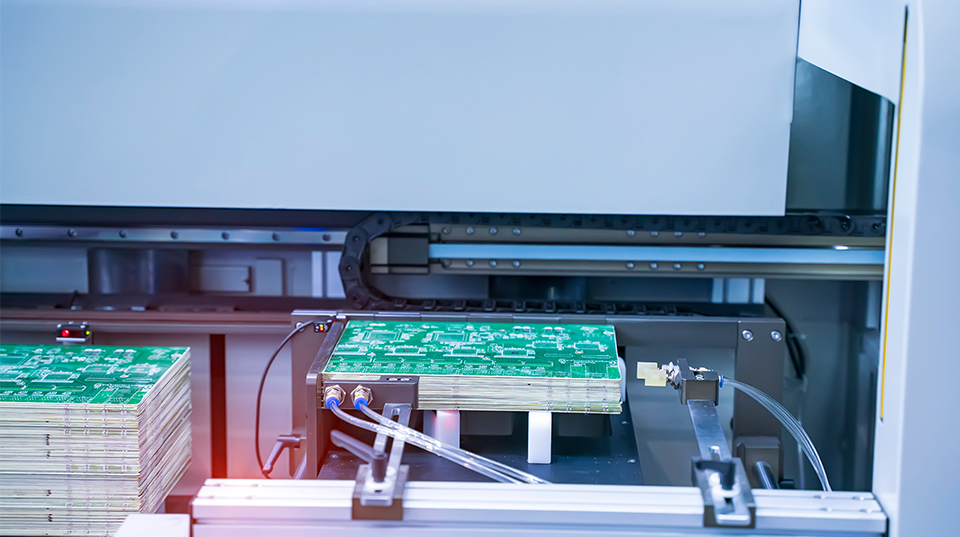

● Automated Production

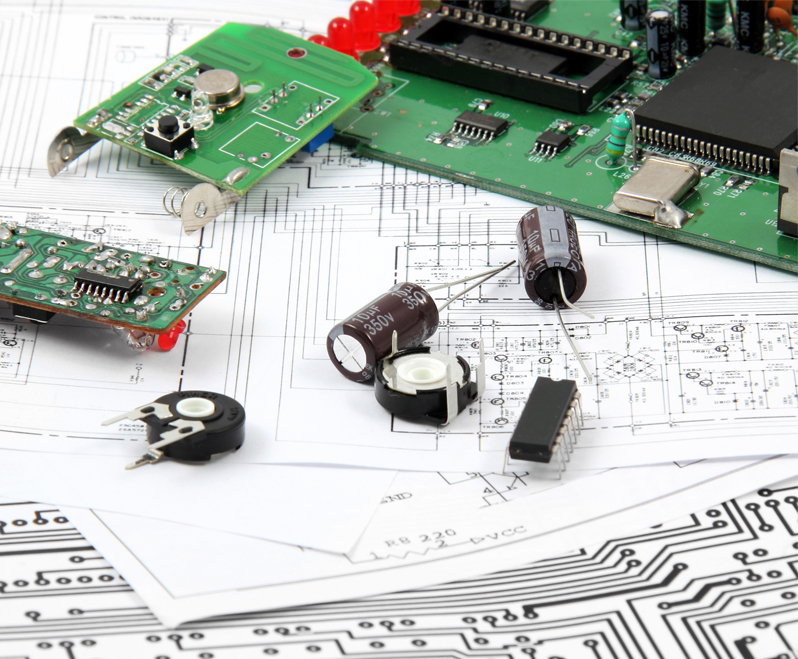

Printed circuit board manufacturing, We use more automated equipment and circuit board technologies, such as automated printing and placement, which can improve production efficiency and accuracy, and reduce the risk of human error.

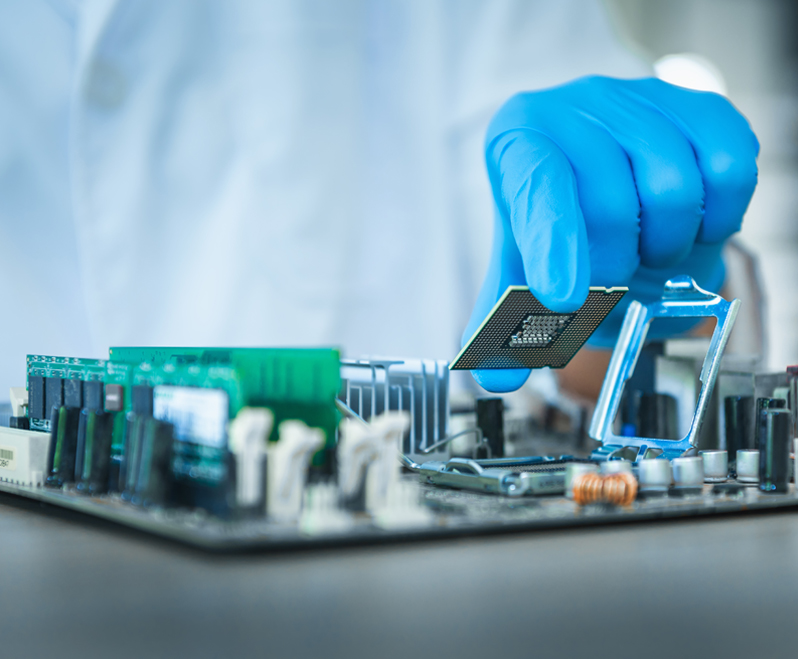

● State-of-the-art Equipment

Invest in the latest printed circuit board manufacturing equipment, such as high-precision cutting machines, drilling machines and surface mount equipment. These devices can provide higher industrial control PCBA quality and precision.

● IPC Standards

Complete production in strict accordance with IPC standards, enabling us to create durable PCB and PCBA that can guarantee product stability

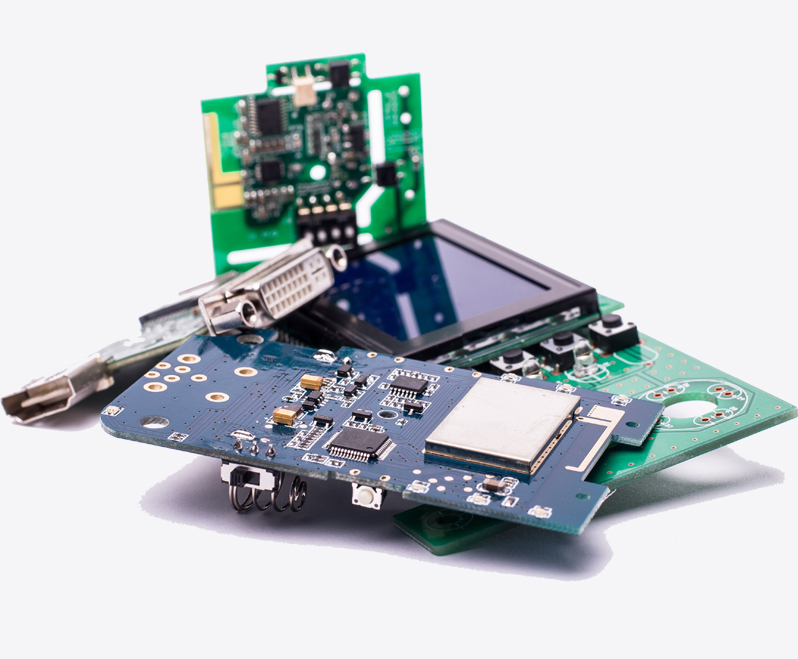

2. Assembly and Kitting

● Quality Control

After years of experience, we PCB assembly team has established a sound quality control system, including inspection, testing, and verification processes. Using high-precision measuring equipment and testing tools to ensure that each printed circuit board meets the specified requirements and standards.

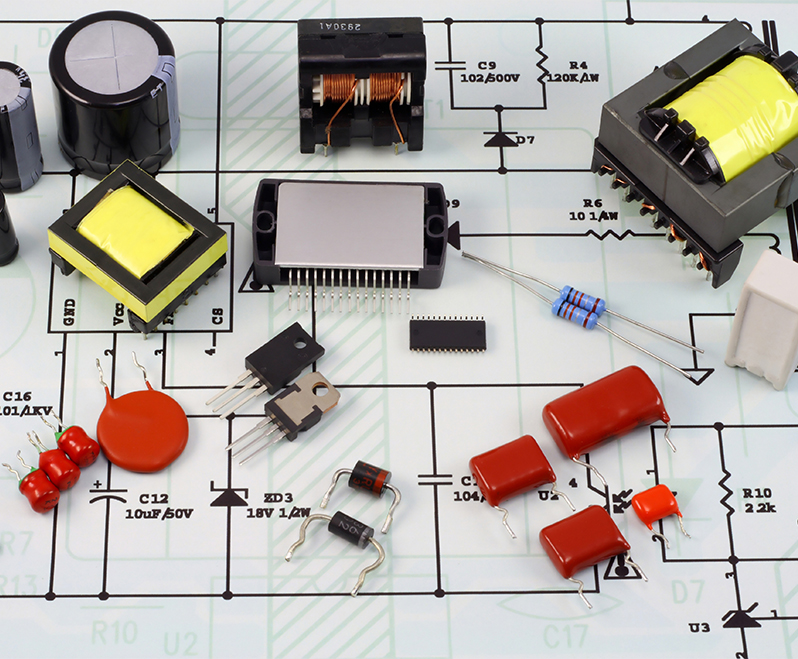

● Material Selection

Select high-quality and reliable materials, such as reliable substrate materials, reliable electronic components, and soldering materials that meet environmental protection requirements. This ensures that the industrial control printed circuit board maintains stability and reliability in long-term use.

● Technical Expertise

During the long-term PCB assembly fabrication production process, our team has mastered various advanced technologies and processes. This includes SMT, DIP, soldering techniques, testing methods, etc. Our team can handle complex and high-density industrial control circuit boards.

3. Strict PCBA Production Process

● Process Optimization

Through years of practice and feedback, our team has optimized the PCBA manufacturing process many times. We have implemented the best processes and operating methods to improve industrial control PCBA production efficiency, reduce costs, and ensure the quality of printed circuit boards.

● Continuous Improvement

We regularly evaluate and improve the PCB assembly manufacturing production process, look for potential problems and bottlenecks, and take corresponding measures for improvement. Improve production efficiency and product quality through continuous optimization and innovation.

● Quality Certification

Our strict quality assurance system has earned us an excellent reputation and is ISO 9001:2015 and IATF16949 certified

4. Perfect After-sales Service

● Problem-Solving Ability

In the long-term PCB assembly fabrication production experience, we have encountered various problems and challenges, such as assembly problems, circuit failures, design defects, etc. By solving these problems, our team has accumulated rich problem-solving abilities and production industrial control PCBA skills.

● Customer Satisfaction

Our team has been operating in the field of PCBA production for 10 years, and we have established a group of loyal customers. They have a sense of trust in our PCBAs and services and are satisfied with our delivery capabilities and the quality level of our industrial control PCBAs.

● Training and Technical Support

We provide the necessary training for our employees to ensure that they are familiar with the latest PCBA manufacturing technology and operating procedures. At the same time, establish a well-trained and experienced technical support service team to provide customers with professional technical consultation and support.