High Reliability and Stability of Beauty Equipment Printed Circuit Board

1. The Importance of Medical Beauty PCBA in Modern Medical Equipment

With the continuous advancement of technology and the rapid development of the medical industry, medical equipment has become an indispensable part of healthcare, and high-frequency PCBs (printed circuit boards) play an essential role in medical beauty devices. These circuit boards are widely used in diagnosis, treatment, and monitoring, and the continuous upgrading of beauty equipment has driven the increasing demand for printed circuit assembly solution development & technical support.

Currently, the global medical equipment market is in a steady growth phase. Factors such as population aging and improved healthcare standards are driving the expansion of the medical beauty equipment sector. As a critical component of these devices, the demand for medical beauty PCB board assembly is also rising. Additionally, the development of 5G technology, the Internet of Things (IoT), and telemedicine has created new opportunities in medical electronics, further fueling the need for high-frequency circuit boards.

With the advancement of integrated circuit technology, medical beauty circuit board will evolve toward high integration, low power consumption, and intelligence, making beauty devices more compact and portable.

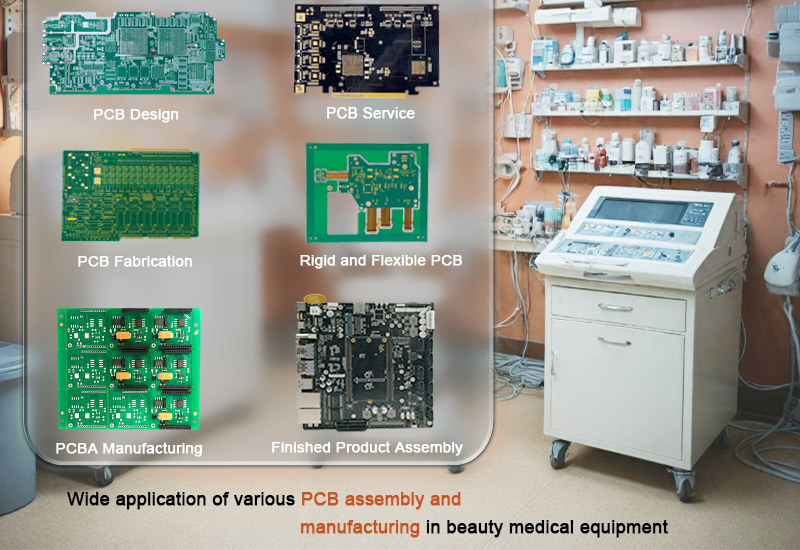

In this context, high-frequency PCB board fabrication, high-frequency circuit board assembly, prototype PCB assembly, PCB fabrication, and PCBA production will play an increasingly significant role in the medical beauty industry. The continuous optimization and innovation of these technologies will provide enhanced solutions for medical beauty circuit board design and manufacturing.

2. Characteristics of Medical Beauty Equipment Circuit Boards

As the core carrier of medical beauty equipment, high-frequency circuit board improves the reliability and performance of the devices by optimizing circuit connections, ensuring that medical beauty equipment functions efficiently.

● High Reliability

In medical beauty equipment, any circuit board failure may affect treatment outcomes and even pose risks to patient safety. Therefore, medical beauty PCB design incorporates advanced high-frequency circuit board manufacturing technology and prototype circuit card assembly processes to ensure exceptional reliability. Through strict quality control and functional testing, every circuit board is designed to operate stably in harsh environments, providing trouble-free protection for medical beauty devices.

● High Stability

Medical beauty equipment must maintain stable performance over long-term operation. Thus, high-frequency circuit boards require a compact layout and optimized material selection to minimize device size while enhancing circuit board stability. This ensures that medical beauty equipment operates efficiently and reliably over extended periods.

● Excellent Anti-Interference Capability

In medical beauty equipment, electromagnetic interference (EMI) can lead to performance degradation or even incorrect diagnostic and treatment results. To prevent this, we utilize advanced high-frequency PCB assembly design techniques to enhance the anti-interference capabilities of circuit boards. Through optimized layout design and shielding technology, beauty equipment circuit boards can effectively resist external electromagnetic interference, ensuring accuracy and operational stability.

By integrating high-frequency printed circuit board design, high-reliability PCBA, and cutting-edge assembly technology, medical beauty circuit boards will continue to support innovation in the industry, offering more efficient and precise solutions for advanced medical beauty applications.

3. One-Stop Medical Beauty Equipment Printed Circuit Assembly Service

● Prototype PCBA Design Scheme

We provide professional prototype circuit board assembly design solutions to enhance high reliability, high stability, and strong anti-interference capabilities. Our optimized designs ensure that each high-frequency PCB operates efficiently and accurately in medical beauty equipment.

● Prototype PCB Assembly

SCSPCBA responds quickly to customer needs, delivering high-quality prototype circuit board assembly services with advanced high-frequency PCB assembly technology to meet the demands of modern medical beauty equipment.

● Finished Product Assembly

From design to production, we offer one-stop high-frequency PCB fabrication and assembly services, ensuring that medical beauty devices are highly reliable, stable, and durable.

● PCB Assembly Manufacturer

Using the most advanced PCB design and manufacturing technology, combined with cutting-edge production equipment and a rigorous quality control system, we produce high-performance high-frequency PCBs and deliver premium medical beauty circuit board assembly services.

At SCSPCBA, we continuously enhance the high reliability, stability, and anti-interference performance of medical beauty equipment printed circuit boards, laying a strong foundation for innovation and technological advancement in the industry.

Choosing SCSPCBA means selecting efficient, precise, and reliable high-frequency PCB solutions for medical beauty equipment. Contact us today to unlock the full potential of your medical beauty devices with our PCBA expertise.