Improving PCB Pad Quality: Common Welding Defects and Solutions

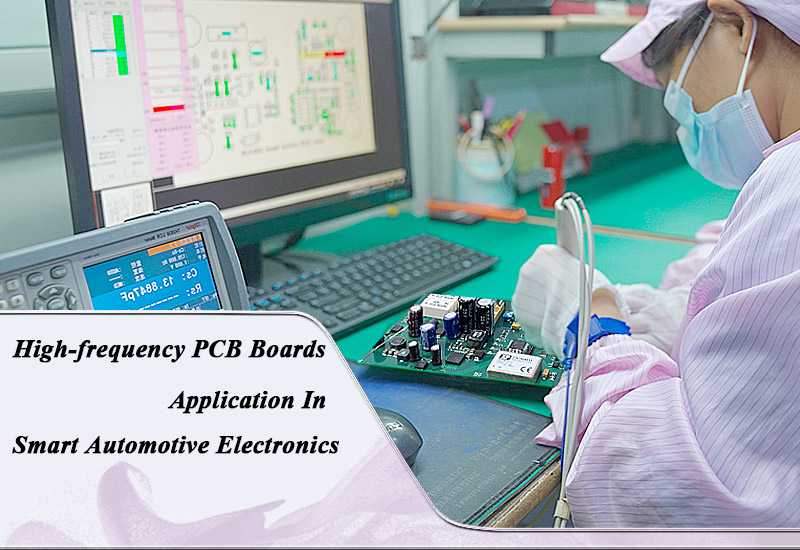

High-frequency PCBs are special printed circuit boards designed to operate at frequencies above 300 MHz, particularly in microwave ranges above 3 GHz. With the rapid development of smart automotive technologies, vehicles demand high-speed signal transmission, advanced driver-assistance systems (ADAS), and powerful computing units. As a result, high-frequency PCBs have become an indispensable component in automotive electronic systems.

1. Why High-Frequency PCBs Are Essential in Smart Automotive Electronics

● High-Speed Data Transmission (High-Frequency Circuit Board for Automotive Communications)

Smart vehicles rely on vast sensor data, requiring fast, stable, and real-time communication. High-frequency PCB boards enable high-speed signal transmission, ensuring low latency and reliable data transfer between radar, cameras, and processing units.

● Signal Integrity Optimization (Signal Integrity-Focused Circuit Design)

Signal integrity is crucial for high-frequency circuits. These circuit boards minimize signal loss, reduce electromagnetic interference (EMI), and provide consistent performance in mission-critical applications like braking or steering control systems.

● High Precision and Reliability (Automotive-Grade High-Frequency PCB)

Advanced materials like Rogers, PTFE, and Teflon manufacture high-frequency PCBs, ensuring thermal stability and electrical precision. These boards meet ISO/TS 16949 and IPC Class 3 standards, making them ideal for harsh automotive environments.

● Thermal Management (High-Frequency Printed Circuit Board with Enhanced Heat Dissipation)

Electric and autonomous vehicles use high-power processors and sensors. High-frequency PCBs are engineered with excellent thermal conductivity, helping dissipate heat and preventing performance degradation or failure.

● Environmental Resistance (Moisture-Resistant High-Frequency PCB)

Thanks to their low water absorption materials, these boards maintain performance in humid, wet, and extreme temperature conditions, providing long-term reliability.

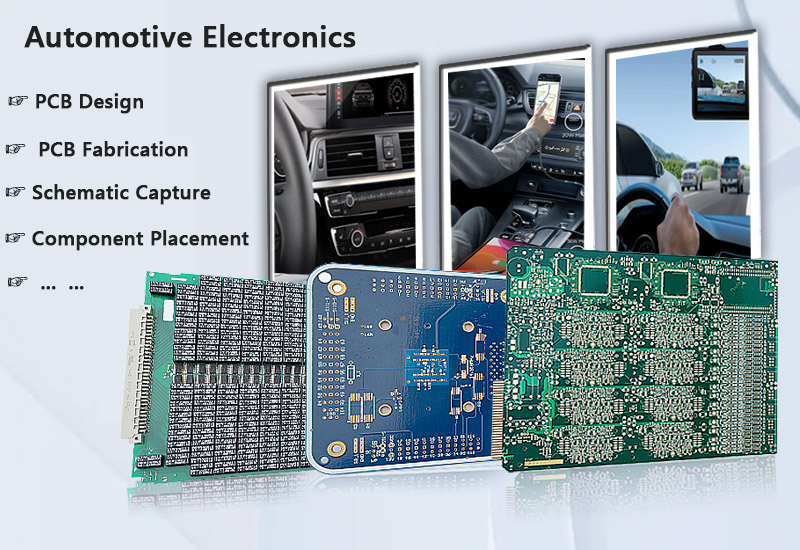

2. Key Applications of High-Frequency PCBs in Automotive Electronics

● Automotive Radar Systems (77GHz Radar PCB)

Millimeter-wave radar systems (24 GHz or 77 GHz) detect objects, monitor lanes, and support collision avoidance. High-frequency PCBs ensure precise signal processing, low noise, and fast response.

● Vehicle-to-Everything (V2X) Communication (V2V/V2I High-Frequency PCB)

Smart vehicles communicate with infrastructure, pedestrians, and other vehicles. High-frequency PCBs enable real-time wireless data exchange in V2X systems, forming the backbone of connected mobility.

● Advanced Driver Assistance Systems (ADAS Printed Circuit Manufacturing)

ADAS features like automatic emergency braking (AEB), lane keeping, and adaptive cruise control rely on low-latency, high-speed PCB and assembly to support decision-making algorithms and sensor data fusion.

● EV Power Management Systems (BMS and Motor Control High-Frequency PCB)

Electric vehicles require accurate voltage and current monitoring. High-frequency printed circuit assembly manages complex power signals in battery management systems (BMS) and inverters, ensuring efficiency and safety.

● In-Vehicle Infotainment Systems (Multimedia PCB for Automotive Use)

Modern vehicles feature touchscreens, voice assistants, and 5G connectivity. High-frequency PCBs enable HD video output, fast data transfer, and noise-free audio performance.

3. Key Equipment Used in Manufacturing Automotive High-Frequency Printed Circuit Board

● Lamination Press (Multilayer PCB Lamination Machine)

Essential for bonding copper layers with dielectric material. Precise lamination reduces signal distortion and dielectric mismatch, critical in high-frequency automotive printer PCB board stack-ups.

● Fully Automatic VCP (Vacuum Compression Press) Line

Vacuum lamination prevents air entrapment, enhancing board strength and signal clarity. This is especially vital for multi-layer high-frequency PCBs in radar and V2X modules.

● Outer Layer LDI (Laser Direct Imaging)

LDI offers high-resolution pattern imaging, enabling high-density interconnect (HDI) PCB design. It ensures minimal distortion, critical for tight tolerance circuits in autonomous driving systems.

4. OEM & ODM Services for Automotive High-Frequency PCB Projects

Our factory supports full OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities for automotive electronics. Whether you need:

-

Custom multilayer high-frequency PCB layouts

-

Rogers/PTFE/Teflon material selection

-

Box Build Assembly: Complete PCB + SMT + final product assembly

-

Prototype to mass production transitions

-

Design consulting for radar, BMS, ADAS and infotainment systems

We offer end-to-end solutions tailored to your specifications. Our engineers work closely with Tier 1 and Tier 2 automotive suppliers to shorten development cycles, optimize cost, and ensure high reliability.

5. Driving the Future with High-Frequency PCB Solutions

As the automotive industry rapidly evolves, high-frequency PCBs are becoming the core enablers of smart mobility. Whether it’s radar sensing, wireless communication, or intelligent control, high-frequency PCBs’ precision, speed, and reliability are indispensable.

With our OEM/ODM one-stop PCBA service support, advanced manufacturing lines, and automotive-grade quality assurance, we are ready to help your next-generation automotive product succeed.

Learn more about expert tips on PCB assembly and electronics manufacturing