One-stop Box Build Assembly Solution: From PCB to Complete Machine Assembly

Box Build Assembly has become an important bridge between electronic design and final products in modern electronic manufacturing. The perfect integration of circuit boards and structural parts determines product performance and affects delivery speed and market competitiveness.

1. What is Box Build Assembly?

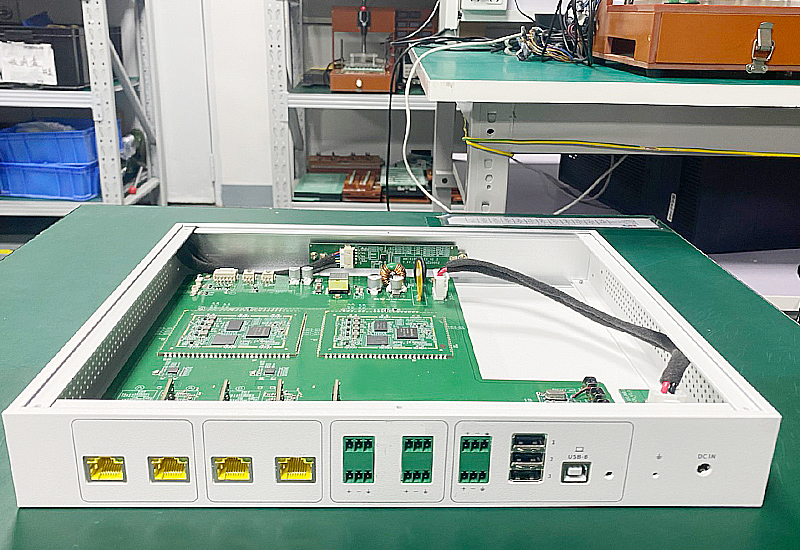

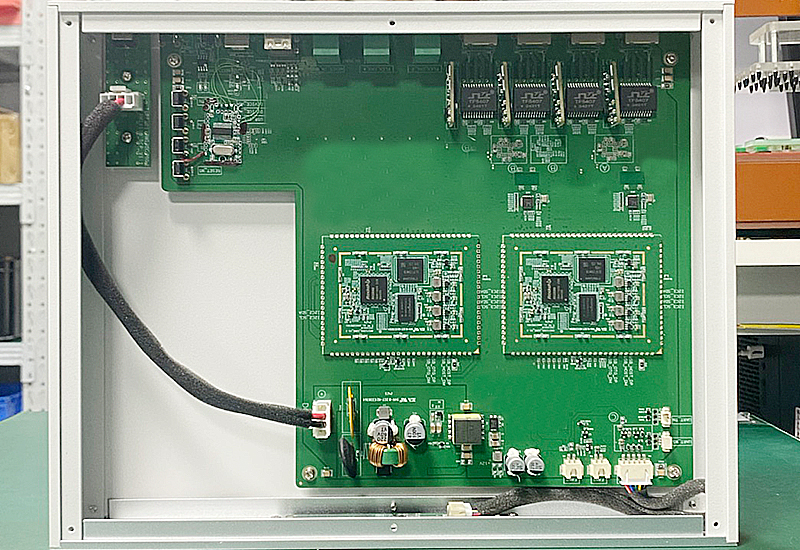

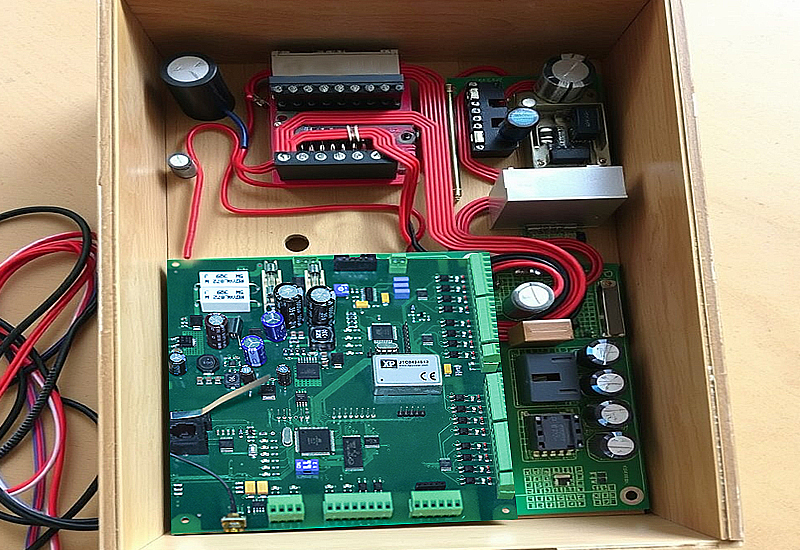

Box Build Assembly, also known as system integration or complete machine assembly, refers to integrating multiple electronic, electrical and mechanical components into a complete package. It goes beyond traditional PCB assembly and covers housing installation, cable connection, functional module integration and final testing. It is one of the most complex and closest links to the final product in electronic manufacturing services (EMS).

2. What Are The Components of Box Build Assembly?

Box Build Assembly usually includes the following key components:

- PCB circuit board: the core of the main control or functional module

- Cables and harnesses: used for signal and power connections

- Power module: adapts to various input/output voltage requirements

- Display/indicator/button: human-computer interaction component

- Structural parts and housing: protect electronic systems and improve the aesthetics of the whole machine

- Fasteners and brackets: ensure that each component is firm and aligned

- Software and firmware: realize functional control and user interaction

3. The Core Role of PCB Board In Box Build

In box build assembly process, circuit board manufacturing is the “nerve center” of the whole system. We have mature DIP and SMT mounting technologies in PCB integrated circuit solution, supporting complex requirements from Double Layer PCB, Multilayer PCB, HDI PCB, Aluminum PCB, Ceramic PCB, Thick Copper PCB, High-Tg PCB to mixed assembly.

- Precise welding to ensure signal integrity and thermal management capabilities

- Integrated test points and interface design to facilitate subsequent system joint debugging

- Support the application requirements of flexible PCB and rigid-Flex PCB

4. Our Box Build Assembly Capabilities

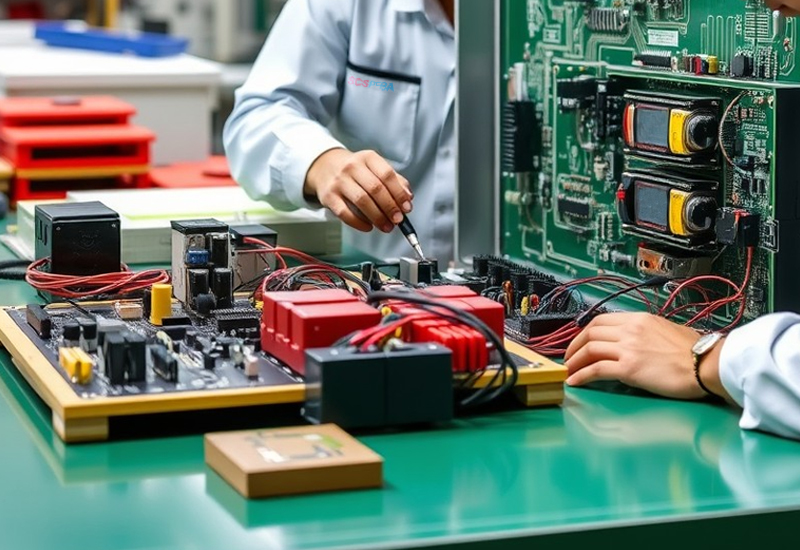

Integrated capabilities from circuit design, electronic components procurement, PCB board fabrication, printed circuit assembly, surface mounting technology, plug-in, structural parts customization, to whole machine testing.

- Full turn-key PCB assembly services: PCB design, PCB fabrication, DFM checking, components procurement, PCB assembly, BGA assembly, firmware programming, functional testing and box-build.

- Precision structure design support: 3D modeling verification, simulate assembly interference in advance

- BOM procurement and material management: original factory authorized channels to ensure delivery time and quality

- Integrated MES traceability system: Each finished product can track component batches and test data

5. Box Build Assembly Application Industries

Box build assembly manufacturing is widely used in the following industries:

| Industries | application |

|---|---|

| Industrial Control | Power control box, Instrument housing |

| Medical Electronics | Wearable health equipment, Detector housing system |

| Communications | Router, Antenna box, 5G base station submodule |

| Smart Home | Smart gateway, Central control system, Security terminal |

| Automotive Electronics | In-vehicle controller, Charging pile main control box |

| Consumer Electronics | Audio system, Smart wearable host |

6. Our Box Build Assembly Process

SCSPCBA printed circuit board manufacturer, adopts a standardized and flexible whole-machine assembly process to ensure product stability and consistency:

● Project Evaluation and DFM Support

– Analyze customer drawings, optimize PCB design, and confirm the feasibility of printed circuit assembly

● BOM Procurement and Material Management

– Carry out full-process electronic components procurement and warehouse material preparation according to the customer BOM

● Printed Circuit Board Assembly

– SMT surface mount technology, AOI/X-ray inspection, functional testing

● Cable/Subassembly Manufacturing

– Homemade wiring harnesses, plastic parts, metal brackets and other parts

● Machine Assembly

– Combining manual and automated processes to complete multi-step system integration

● Testing and Verification

– Functional testing, aging testing, waterproofing/drop testing

Packaging and Shipping

– Customized packaging, anti-static/shockproof treatment