Enhancing Industrial Control Systems with Reliable and Cost-Effective PCBA

Reliability and precision are crucial in the industrial control industry. Failure of industrial controllers can have serious consequences, including production interruptions (costing millions to tens of millions of yuan), equipment damage, product quality degradation, and even safety incidents such as explosions and leaks, threatening the environment and human life. Therefore, industrial control PCB manufacturing assembly (printed circuit board assemblies) plays a crucial role. Highly reliable PCBAs reduce downtime, improve production efficiency, and lower defective product rates, while also driving industrial upgrades towards intelligent and automated processes.

✅ The Role of PCBA in Industrial Control Systems

PCBAs are not only the “brains” of industrial control systems, responsible for processing and executing various control commands, but also integrate multiple functional modules, making them the core vehicle for intelligent and automated operation of industrial control systems. Key applications include:

1. Driving Intelligent Manufacturing

In industrial control systems, PCB manufacturing and assembly are responsible for controlling the robot’s motion trajectory, movement sequence, and force. For example,

- In industries like electronics manufacturing and machining, industrial robots are widely used in automated production. Industrial control PCBA, acting as the robots’ brains ensure precise operation.

- In automated production line control systems, circuit assembly serve as the core control unit, coordinating the actions of various production processes, such as robotic gripping, conveyor belt operation, and welding equipment startup. This ensures stable production line operation and improves production efficiency and product quality.

2. Data Processing and Communication

Printed circuit board assembly possesses powerful data processing and communication capabilities, integrating data from various sensors, such as position sensors, force sensors, and vision sensors. This enables robots to perceive their own state and surrounding environment, making informed decisions and improving operational accuracy and safety.

- In intelligent warehouse management systems, industrial control PCB board assembly are used to automatically store, retrieve, and sort goods, improving warehouse management efficiency and accuracy while reducing labor costs.

3. Improve Production Flexibility and Precision

PCB and assembly’s high-precision, high-speed, and high-reliability control capabilities improve production flexibility and precision, reducing reliance on manual labor. For example:

- Household cleaning robots, the PCBA control board must integrate multiple functions, including motor drive, sensor control, and wireless communication, to enable autonomous navigation, intelligent obstacle avoidance, and user interaction. Advanced algorithms and efficient data processing capabilities enable the robot to plan the optimal cleaning path and adjust its motion state in real time, ensuring efficient cleaning.

4. Ensure System Reliability

High-quality printed circuit board assembly manufacturers are equipped with professional testing equipment such as X-ray, AOI, flying probe testing, and reliability laboratories to eliminate counterfeit and substandard materials. Standardized processes, from solder paste printing accuracy to reflow soldering temperature profiles, adhere to IPC-A-610 Class 2/3 standards throughout the entire PCB manufacturing process to ensure soldering reliability. Adapting to the characteristics of industrial boards, conformal coating processes are added to ensure the long-term stability of industrial control systems

5. Accelerate product launch and iteration.

This one-stop PCBA solution provides comprehensive coordination, leveraging scale and industry databases to proactively identify materials and optimize alternatives, thereby alleviating the burden of sourcing and waiting for electronic components for customer R&D and production departments. This seamlessly integrated process directly integrates material procurement, inspection, and warehousing with SMT production lines, reducing transfer steps and shortening overall lead times. This helps accelerate product launch and iteration, meeting the demands of accelerated iteration cycles for industrial equipment

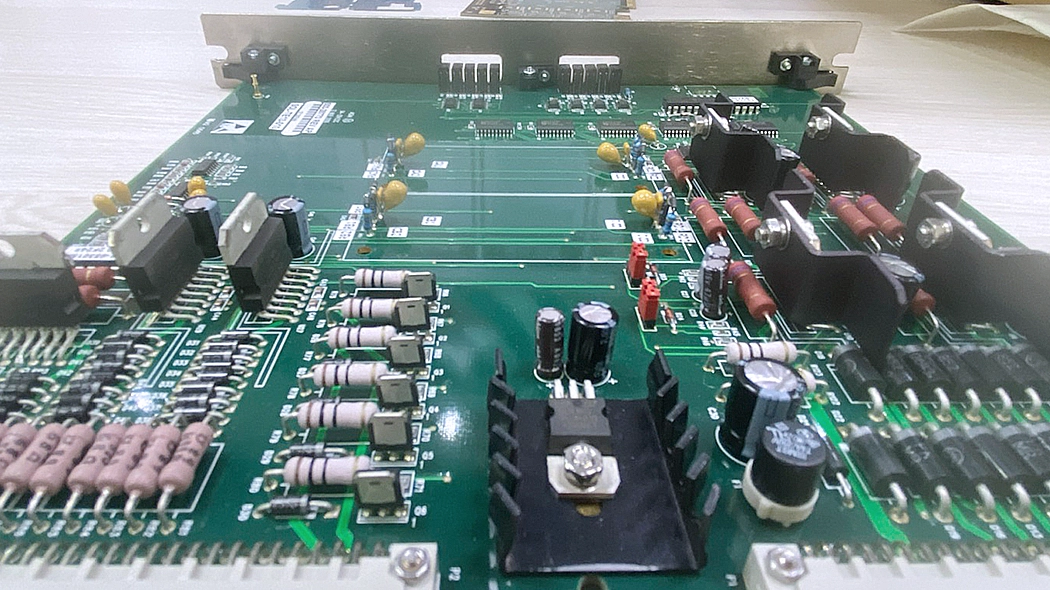

✅ Industrial PCB Assembly Reliability Characteristics

The design of industrial PCB assemblies requires consideration of multiple reliability characteristics to ensure long-term stable operation in harsh environments. Key reliability characteristics include:

- Material Selection

Circuit board are manufactured using high-quality, heat-resistant, and corrosion-resistant materials, such as high-temperature resistant materials (FR-4 TG150+ and polyimide), to ensure stable performance in complex and changing industrial environments. - PCB Layout

Advanced circuit design concepts and optimization algorithms are employed to achieve a rational distribution of signal layers and optimized configuration of power and ground planes. - Manufacturing Process

Strict control of the printed circuit board manufacturing process, the introduction of sophisticated production equipment and technology, and meticulous circuit design and precise processing ensure the quality and performance of PCB board fabrication. - Protection Mechanisms

Overcurrent and overvoltage protection circuits are implemented to address unexpected situations. - Environmental Testing

PCBs undergo rigorous environmental and life testing to ensure stable operation under extreme conditions. Electromagnetic - Compatibility Design

Focuses on the PCB board electromagnetic compatibility design, minimizing the impact of electromagnetic interference through rational layout and routing. - Heat Dissipation Design

Optimizes heat dissipation to reduce trace length and complexity, lowering power consumption and heat generation.

These design optimizations ensure the robustness of PCB assembly and manufacturing in harsh environments, extending product lifespan and minimizing downtime.

✅ Cost Reduction Strategies in Industrial PCBA Manufacturing

While reliability is critical, cost efficiency cannot be overlooked. Leading industrial pcb assembly manufacturers employ smart design and sourcing strategies to reduce PCBA cost without compromising performance:

- DFM (Design for Manufacturability) to simplify layouts and improve yield

- Alternative component sourcing to avoid shortages and high prices

- Automated SMT lines to ensure precision and reduce labor costs

- Batch testing and functional inspection to cut rework expenses

These strategies help customers achieve optimized cost-to-performance ratios across printed circuit board production volumes.

✅ Ensure High Reliability and Quality Assurance

Industrial control assembled circuit board directly impacts equipment stability and production safety, requiring them to meet three key requirements: long-term trouble-free operation, precise signal transmission, and strong anti-interference capabilities. Therefore, PCB board makers employ comprehensive process control:

Key Controls

- Raw Material Control:

Industrial-grade components (such as solid-state capacitors and high-temperature-resistant chips) are used

FR-4 fiberglass epoxy resin is preferred for PCB substrates

Ensuring stable operation in a wide temperature range of -40°C to 85°C

Humidity testing is performed for 96 hours - Process Control:

Surface mounting technology: high-density component placement is achieved through solder paste printing and reflow profile control (preheating, soaking, reflow, and cooling)

DIP: High-power devices (such as relays and connectors) are processed using a plug-in process - Full-Process Inspection:

Automated Optical Inspection (AOI) identifies solder joint defects

X-rays inspect hidden solder joints such as BGAs.

ICT in-circuit testing verifies circuit connectivity

FCT functional testing ensures module performance meets standards.

System Assurance and Continuous Improvement

- Standardized System:

Requires ISO9001:2008 certification and clear operating instructions (including personnel qualifications, equipment specifications, and environmental cleanliness). - Full Process Traceability:

Records are maintained throughout the entire process, from component batches to welding parameters and test data, enabling accurate identification of quality issues.

✅ Partner with a Trusted Industrial PCBA Manufacturer

In the industrial control sector, selecting a reliable PCBA manufacturer requires a comprehensive assessment of technical capabilities, quality systems, and industry experience. The following are key factors and recommended manufacturers:

Core Partnership Standards

- Technical Capabilities and Qualifications

- High-precision placement technology (such as BGA 0.15 pitch placement) and full-process service capabilities (SMT, testing, and assembly) are required.

- ISO9001 and IATF16949 certifications are required to ensure compliance with industrial-grade reliability requirements.

- Supply Chain and Delivery Assurance

- Preferred suppliers include those with flexible supply chains, such as multi-factory collaboration to mitigate geopolitical risks.

- Daily production capacity must match demand, and expedited orders must be supported.

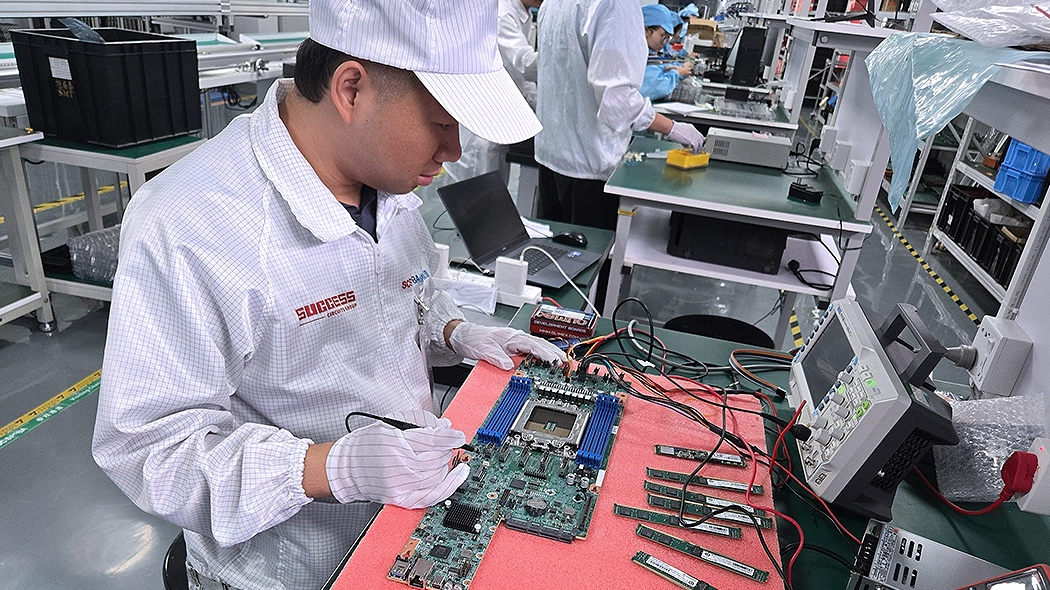

Choosing an SCSPCBA Manufacturer and Its Advantages

SCSPCBA, with its comprehensive, one-stop PCBA solutions, combines technological strength, cost optimization, and high reliability, making it a trusted partner for global industrial control and automation companies.

1. Proven Industrial Control PCBA Expertise

SCSPCBA has over a decade of experience in industrial PCB assembly services and possesses a deep understanding of the requirements of automation systems, control boards, and sensor modules.

Our engineering team works closely with customers from design to production to ensure that every circuit board meets industrial-grade reliability standards.

2. Cost Optimization through Smart Manufacturing

At SCSPCBA, reducing PCBA costs doesn’t mean sacrificing quality. We implement a multi-layered cost control strategy:

Efficient component sourcing through global partnerships with authorized distributors

An AI-driven material management system effectively prevents stockouts and excess inventory

High-speed SMT and automated test lines minimize labor and rework costs

Design optimization recommendations improve yield and reduce unnecessary complexity

3. High-Reliability Manufacturing for Harsh Environments

Industrial PCBs must withstand high temperatures, vibration, and continuous operation. SCSPCBA utilizes advanced materials and processes to create rugged and durable PCBAs for harsh environments:

Conformal coating and selective potting ensure dust and moisture resistance

Thick copper layers and reinforced vias for high-current applications

Comprehensive reliability testing, including vibration, thermal cycling, and salt spray testing

4. Strict Quality Control and Traceability

SCSPCBA adheres to ISO9001, ISO14001, and IATF16949 quality management systems. Each production stage is rigorously monitored through the following:

Automated Optical Inspection (AOI)

X-ray Solder Joint Verification

In-Circuit Test (ICT) and Functional Test (FCT)

Full-process traceability from component to final shipment

Our customers benefit from consistent quality, minimal defect rates, and complete visibility into every stage of production.

5. One-Stop PCBA Service: From Design to Delivery

Unlike traditional assembly plants, SCSPCBA provides end-to-end industrial PCBA manufacturing services:

PCB design and layout optimization

Component sourcing and BOM cost control

SMT and DIP assembly

Functional testing and final product assembly

Global logistics and after-sales technical support

Partnering with a reliable manufacturer like SCSPCBA means more than just outsourcing assembly—it ensures that every circuit board you need for your industrial control system is manufactured with high precision, reliability, and cost competitiveness.

From rugged PCBAs for harsh environments to high-speed automation modules, SCSPCBA supports your business with intelligent manufacturing, reliable quality, and complete peace of mind.