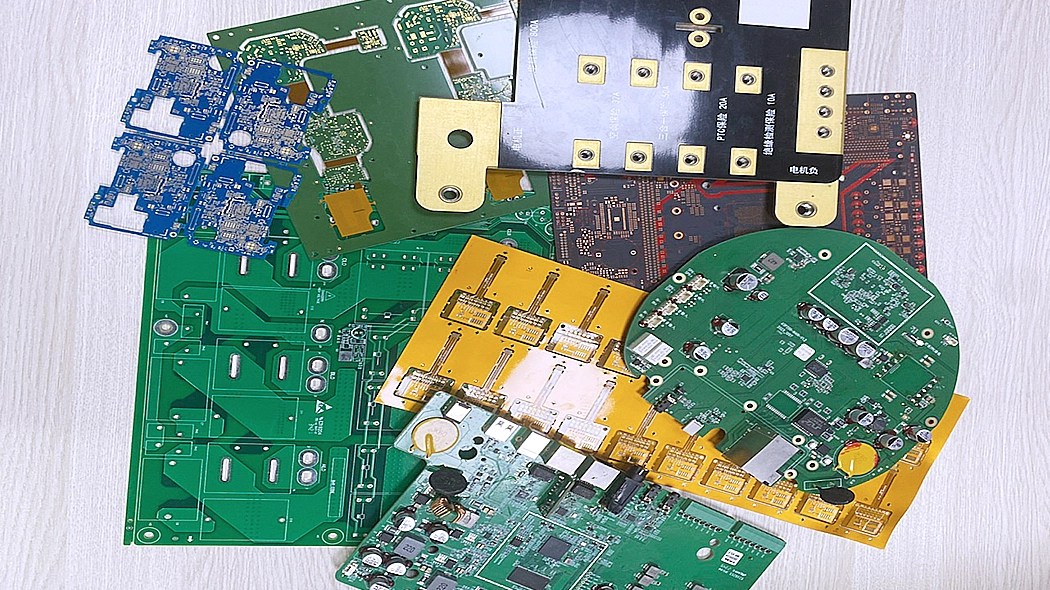

Enhancing Industrial Control Systems with Reliable and Cost-Effective PCBA

Many engineers and purchasing managers face the same challenge — how to choose a reliable PCBA manufacturer in China. After all, producing high-quality PCB assemblies is not a simple task. It’s a complex and precision-driven process that involves every stage — from the initial communication and circuit design, to component sourcing, SMT assembly, testing, and finally box build integration and functional verification. Each phase requires strict process control, technical expertise, and a commitment to quality.

To support global engineers, product developers, and procurement specialists, we’ve prepared this industry insight to help you identify the key criteria for selecting a trusted PCB manufacturing and assembly partner in China. You can ensure your electronics projects are delivered with precision, efficiency, and confidence by evaluating factors such as production capability, R&D strength, supply chain stability, quality control, delivery reliability, customization options, and sustainability standards.

1. Printed Circuit Board Production and Manufacturing Capabilities

(1) Layer range

- Single/double-sided PCB → Multi-layer PCB

- Batch processing: 1-16 layers

- Sample PCB: 1-16 layers

- Up to 24 layers

(2) Trace width/spacing

Minimum trace width/spacing up to 2.5mil/3mil (approx. 0.064mm/0.076mm)

(3) Hole accuracy

- Machine drilling 0.2mm

- Laser drilling 0.1mm (tolerance ±0.01mm)

- Supports ultra-thin board thickness of 0.15mm and fine pitch of 0.25mm

(4) Via Process

- Tenting

- Uncovered

- Plug with SM

- Epoxy-filled & Capped

(5) Surface Finish

- HASL Lead Fre

- Immersion Gold (1U)

- Immersion Gold (2U)

- Immersion Gold (3U)

- Immersion Gold (4U)

- Immersion Gold (5U)

- Immersion Ti

- Immersion Silve

- OS

- OSP+Immersion Gold(1U

- OSP+Immersion Gold(2U)

(6) Material Coverage

- Supports special boards such as FR-4, PTFE, PI, aluminum-based, and ceramic.

(7) Production Capacity

- Monthly output exceeds 100,000 square meters.

- Suitable for SMT and DIP assembly of multilayer, high-density, and high-frequency circuit boards.

- Suitable for BGA, QFN, and fine-pitch component assembly for complex electronic products.

- Functional and ICT testing to ensure the reliability of the final application.

- Complete assembly and full product integration.

Note: Advanced SMT production lines equipped with AOI, SPI, and automated reflow ovens ensure consistent PCB assembly quality, which is crucial for the automotive, medical, and consumer electronics industries.

(8) Delivery Capability

- Rush orders can achieve 24-hour sample delivery and 72-hour small-batch shipment.

Capacity varies among different manufacturers; special processes (such as resin-filled vias and mixed-pressure boards) require separate review.

Supports circuit boards made of special materials such as multilayer PCB, high-density PCB, HDI, and high-frequency PCB

2. Technology and R&D Expertise

Technology and R&D strength refer to the precision machining, material application, and process optimization technologies involved in PCB board production. These are key indicators of a PCB and PCBA manufacturer’s overall production capabilities. In the electronics manufacturing industry, innovation and precision engineering determine not only product reliability but also its scalability and performance across various applications.

(1) High-precision manufacturing capabilities

- Supports stable mass production of 1-20 layer multilayer PCB

- Achieves minimum line spacing of 2mil/3mil and minimum hole diameter of 0.1mm, using LDI laser direct imaging technology to improve production efficiency by over 30%

- Chinese printed circuit board assembly manufacturers typically use high-precision SMT production lines capable of mounting components as small as 0.1005 (0.4 × 0.2 mm) with an assembly accuracy of ±0.03 mm.

(2) Breakthrough in PCB Materials Technology

- High-frequency materials such as Rogers RO4350B are widely used in the 5G communication field, achieving insertion loss as low as 0.15dB/inch in the 28GHz band.

- Automotive electronics utilize a 2oz thick copper design combined with FR-4 TG170 material, passing 1000 temperature cycle tests (-40℃~125℃).

(3) Advanced Optical Inspection Systems

- AOI (Automated Optical Inspection) and SPI (Solder Solder Paste Inspection) have become standard features for real-time quality monitoring.

- X-ray inspection technology is used to inspect BGA and QFN packages to ensure solder joint integrity.

(4) Process Innovation Directions

- High-frequency, high-speed PCBs employ impedance control (±5%) and special surface treatment processes to meet the requirements of millimeter-wave communication.

- Leading manufacturers are committed to multilayer PCB design optimization, impedance control, and thermal management technologies to support high-frequency and high-power electronic applications.

- PCB assembly manufacturers provide Design for Manufacturability (DFM) and Design for Assemblability (DFA) feedback early in the design process, thereby reducing production defects and improving overall yield.

(5 ) R&D Capabilities

- A typical R&D department includes experts in signal integrity analysis, stack-up design, and high-speed data transmission simulation to ensure that final components meet electrical performance requirements.

- Some manufacturers also employ AI-driven inspection and intelligent manufacturing execution systems (MES) to enhance traceability, process control, and production efficiency.

- The combination of technological depth, R&D experience, and advanced equipment enables manufacturers to handle complex components such as high-density interconnect (HDI) boards, flexible/rigid PCBs, and automotive-grade electronics.

3. Supply Chain Management and Component Sourcing

Efficient supply chain management is a defining factor in the overall reliability of any PCBA manufacturing process. In China’s electronics manufacturing sector, maintaining a stable and transparent supply chain directly impacts cost control, lead time, and the quality consistency of the final assemblies.

Most established PCB and PCBA manufacturers work with a dual-layer supply chain system—authorized global distributors and verified local suppliers. This ensures that 100% genuine components are used and reduces the risk of counterfeit or obsolete parts entering production. Procurement partners typically provide traceable components with full certification.

On average, component procurement lead times for standard electronic parts range from 2 to 4 weeks, while specialized or high-frequency components may extend to 6–8 weeks, depending on global inventory conditions. To mitigate disruptions, many manufacturers maintain safety stock systems or alternative sourcing lists, particularly for critical ICs, connectors, and passive components.

A typical PCBA supply chain process includes:

- BOM verification and cross-checking against authorized databases

- Component traceability tracking using barcode or QR systems

- Incoming quality inspection (IQC) for visual, functional, and electrical verification

- Batch-level record management through ERP or MES systems

In well-managed facilities, the component defect rate after IQC is usually below 0.1%, and overall on-time material availability exceeds 95%. Manufacturers equipped with real-time procurement tracking and inventory visibility systems are better positioned to ensure on-time PCB assembly delivery, even under volatile market conditions.

Additionally, growing environmental and compliance requirements have pushed many suppliers to conform to RoHS, REACH, and Conflict Minerals Reporting (CMRT) standards. These practices not only improve global supply chain transparency but also align with international ESG expectations for sustainable electronics manufacturing.

Electronic component (resistors, capacitors, IC chips) material management warehouse

4. Production Flexibility and Lead Time Management

In modern electronics manufacturing, production flexibility and delivery cycle management are key performance indicators for measuring a manufacturer’s ability to simultaneously meet the needs of both OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) customers. These capabilities ensure that printed circuit board assembly manufacturers can efficiently and reliably meet customers’ diverse needs from early PCB prototyping to large-scale commercial production.

(1) Production Flexibility: Balancing Customization and Efficiency

Production flexibility is reflected in the ability to quickly respond to order changes and adapt to diverse product needs.

- Equipment and Process Support:

Utilizing automated production lines, a typical Chinese PCBA manufacturer operates multiple SMT production lines, each capable of mounting 80,000 to 120,000 components per hour with an accuracy of ±0.03 mm. - Advanced Systems:

Intelligent management systems support the switchover between small-batch customization and large-scale production. For example, a U-shaped production line layout helps reduce material handling time and improves production line adjustment efficiency. - Order and Scheduling Optimization:

By proactively optimizing the order model and incorporating switchover time into production scheduling, equipment preparation time is reduced for multi-product production. Simultaneously, a priority management system is established to prioritize urgent orders.

This allows the PCB assembly manufacturer to simultaneously handle both multi-product, small-batch and low-product, large-batch projects. This flexibility is particularly important for OEM customers who need to manage product diversity and ODM customers who require rapid design iteration.

(2) Delivery Cycle Management: Full-Process Control Strategy

- Production Process:

Optimize multi-layer PCB production processes, introduce quality control technologies such as AOI and X-ray inspection to reduce rework and shorten production cycles. - Supply Chain Collaboration:

Establish a supply chain system with suppliers, maintain safety stock of key components, address raw material shortage risks, avoid production stoppages due to material shortages, and ensure the continuity of printed circuit board production. - Emergency Mechanism:

Develop contingency plans, monitor PCB board fabrication progress in real time, and quickly adjust resource allocation when delays occur.

(3) Delivery Time Varies Depending on Project Type

- Prototype assembly:

Typically 3-7 business days, depending on component availability and design complexity. - Medium-volume production:

Typically completed within 10-15 business days after materials are ready. - High-volume production:

20-30 business days, including final testing and packaging.

Efficient manufacturers use MES (Manufacturing Execution System) to track production progress in real time, enabling precise scheduling and traceability across all stages, from stencil printing and reflow soldering to inspection and assembly. Integration with ERP systems also ensures synchronized updates to material planning, logistics, and quality reports.

For OEM/ODM electronics customers, this flexibility helps them launch products faster, optimize costs, and achieve scalable production without sacrificing quality. By maintaining a good balance between automation, skilled labor, and process standardization, Chinese PCBA manufacturers can achieve consistent on-time delivery, a key factor in the reliability of the global supply chain.

5. Quality Control and Certifications

A robust quality control system is the foundation of any reliable PCB assembly and manufacturing process. Given the complexity of modern electronic assemblies, consistent quality assurance requires a combination of process standardization, multi-stage inspection, and international certification compliance.

Most PCB and PCBA manufacturers in China implement a layered quality management framework covering IQC (Incoming Quality Control), IPQC (In-Process Quality Control), and FQC (Final Quality Control). At each stage, data-driven monitoring ensures that deviations are detected early and corrected before final delivery.

(1 )Typical inspection and testing technologies include:

- AOI (Automated Optical Inspection) —— solder paste and component placement verification

- SPI (Solder Paste Inspection) —— paste volume and alignment accuracy

- ICT (In-Circuit Testing) —— short/open circuit detection and electrical continuity verification

- X-ray inspection —— hidden joint analysis on BGA and QFN components

- FCT (Functional Circuit Testing) —— confirm performance under real operating conditions

In quantitative terms, advanced facilities maintain first-pass yield rates above 98%, and overall defect per million levels below 1000 ppm, depending on assembly complexity and component density.

PCB and PCBA Inspection and Testing Technologies

(2)Common certifications include

Certification plays an equally vital role in ensuring reliability and global market compliance.

- ISO 9001: General quality management standard

- ISO 13485: Medical device manufacturing compliance

- IATF 16949: Automotive electronics quality system

- UL safety certification: Fire and material safety for PCB substrates

- RoHS, REACH, and CE compliance: Environmental and chemical safety standards

- IPC-A-610 Class 2 or Class 3 workmanship standards —— ensuring that assemblies meet specific reliability grades for industrial or aerospace applications.

In addition to product-level validation, many facilities perform environmental stress screening (ESS), temperature cycling, and vibration testing to verify long-term durability and solder joint stability. These verification protocols are critical for sectors such as automotive, medical, and aerospace electronics, where operational reliability is paramount.

The integration of certification-based management systems, automated inspection, and traceable data analytics has made modern Chinese printed circuits assembly corporation capable of achieving global quality benchmarks, meeting both OEM/ODM electronics production requirements and stringent export standards.

6. Industry Applications and Compatibility

The versatility of Printed Circuit Board Assembly makes it essential across a wide range of industries, each with unique requirements for performance, safety, and reliability. In China, many manufacturers specialize in producing customized PCB assembly and manufacturing solutions for automotive electronics, medical devices, industrial control systems, and consumer electronics, ensuring compatibility with strict regulatory standards and technical demands.

(1) Automotive Electronics

Automotive electronics require a high-reliability PCBA board capable of performing under extreme conditions, including temperature fluctuations, vibrations, and exposure to chemicals. Typical applications include infotainment systems, advanced driver-assistance systems (ADAS), powertrain control modules, and battery management systems.

- Key requirements:

- Thermal management for heat dissipation

- High-speed PCB design for data-intensive applications

- Compliance with IATF 16949 for automotive manufacturing quality

- Automotive-grade components and RoHS-compliant materials

Manufacturers producing automotive PCB assemblies often perform temperature cycling and vibration testing to ensure durability under real-world driving conditions. Some also employ automotive-grade connectors and low-resistance solder joints for enhanced reliability.

(2) Medical Electronics

The medical electronics sector requires high-precision PCBA to ensure the safety and effectiveness of medical devices, such as patient monitoring systems, defibrillators, diagnostic equipment, and wearable health trackers. These assemblies must comply with stringent ISO 13485 standards, ensuring that they meet medical device manufacturing quality.

- Key requirements:

- Biocompatible materials and lead-free solder

- High reliability and low failure rates

- Adherence to EMC (electromagnetic compatibility) and ESD (electrostatic discharge) standards

- Comprehensive validation through functional circuit testing (FCT)

Due to the critical nature of medical devices, manufacturers often perform environmental stress screening (ESS) and regulatory certifications (e.g., CE, FDA approval) to ensure that the devices function as intended without risk to patient safety.

(3)Industrial Electronics

For industrial control systems, automation equipment, and robotics, PCB fabrication and assembly must withstand harsh operating environments, including high voltages, extreme temperatures, and dust or moisture exposure. Industrial electronics applications typically include motor control boards, sensors, and programmable logic controllers.

- Key requirements:

- Durability and robustness against physical stress

- Wide temperature range and anti-corrosion coating

- Compatibility with Industry 4.0 IoT and automation protocols

- Functional testing under load conditions

Manufacturers for this industry typically perform extensive durability testing, including shock and vibration testing and long-term burn-in cycles, to ensure system reliability in 24/7 industrial environments.

(4) Consumer Electronics

The consumer electronics sector represents one of the largest markets for printed circuit assembly, ranging from smartphones and laptops to smart home devices and wearables.

- Key requirements:

- Miniaturization for compact, lightweight designs

- High-speed data transmission for multi-functional devices

- Quick prototyping and fast time-to-market

- Compliance with CE, FCC, and RoHS standards

Due to the mass production nature of consumer electronics, rapid PCB prototyping and automated testing are crucial to maintaining high output while ensuring quality consistency across large production volumes.

Manufacturers provide customized PCB assembly and manufacturing solutions for multiple industries

7. Delivery and After-Sales Service

Assembled circuit board delivery and after-sales service encompass guaranteed delivery efficiency, after-sales repair commitments, a quality control system, and customer support mechanisms.

(1) Delivery Process and Efficiency Guarantee

- Delivery Cycle

Standard repair time is 2-3 business days; expedited service is 1-2 business days (excluding special components requiring off-site ordering). - Customized Services

support the processing of flexible circuit boards, high-tg PCB, multilayer boards, and other special specifications, and provide free prototyping design solutions. Before delivery, we conduct multi-dimensional quality inspections including AOI automatic optical inspection and flying probe testing.

(2) Core Content of After-sales Service

| Fault Types |

Common Problem Examples |

Troubleshooting Methods |

|---|---|---|

| Mechanical component wear | Worn paper take-up teeth and stretched chain | Replace worn parts and adjust clearance |

| Circuit malfunction | Touchscreen malfunction, servo driver overcurrent alarm | Detect module damage, repair or replace circuit board |

| Printing quality issues | Double sheet feeding, unstable paper transfer | Adjust the position of the blower foot and paper stop brush |

(3 ) After-sales Support and Value-Added Services

- Technical Support:

Provides installation, commissioning, and operation training; regular customer feedback collection; 7/24 response time; responds within 30 minutes of receiving notification; - Supply Chain Guarantee:

Interconnected with systems to ensure rapid allocation of repair materials; provides a reserve of consumable parts to minimize downtime.

8. Customization and Solution Flexibility

printed circuit board assembly manufacturers’ customized solutions cover the entire process of circuit design, production, and testing, meeting the personalized needs of multiple industries. Their core advantages lie in technology adaptation, cost optimization, and rapid response.

(1) Core Contents of Customized Solutions

PCBA customized solutions provide manufacturers with a full-process service from PCB design to delivery based on customer needs, including:

- Design Stage

Circuit layout optimization (e.g., HDI technology), BOM matching, and DFM analysis - Production Stage:

Support for PCB production (minimum order of 1 piece), diverse substrates (FR4/aluminum substrate), and rapid prototyping - Testing and After-sales:

Functional testing, aging testing

(2) Advantages of Choosing a Customized Solution

- Precise matching of needs:

For example, medical devices require strict safety standards, and manufacturers can customize PCBAs that comply with ISO 13485. - Cost optimization:

Reduce production costs by more than 15% through DFM analysis, reducing material waste. - Rapid response:

Flexible delivery from prototype to mass production, shortening the product launch cycle

9. Choosing A Reliable PCB Assembly Manufacturer

Selecting a reliable PCBA manufacturer in China requires evaluation across multiple dimensions: manufacturing capabilities, R&D strength, supply chain management, production flexibility, quality control, industry experience, delivery reliability, and customization capabilities. Prioritizing these factors ensures high-quality PCB assembly, timely delivery, and compliance with regulatory requirements, thereby increasing project success rates and long-term partnership value.

Partner with SCSPCBA, a leading PCBA manufacturer in China, for fast printed circuit board prototyping, flexible batch production, and reliable PCB assembly solutions. Contact us today to ensure quality, on-time delivery, and expert support for your electronics projects.