(2) Electric Vehicles (EVs) — HDI Boards and Automotive-Grade Reliability

In new energy vehicles, PCB board assembly plays a critical role in BMS (Battery Management Systems), motor control units (MCUs), and on-board chargers (OBCs).

- Use of HDI boards with stacked microvias for high-current and high-density designs.

- Automotive-grade reliability verified under AEC-Q200 and IATF 16949 standards.

- Embedded thermal vias and copper base layers ensure excellent heat dissipation and vibration resistance.

Case Study:

A leading electric vehicle manufacturer has developed a battery management PCB boards that is five times more valuable per square meter than traditional automotive circuit boards, while maintaining excellent performance in environments ranging from -40°C to +125°C.

Smart grid technologies require real-time data communication, energy routing, and fault isolation, demanding high-frequency, low-loss PCB materials and robust EMC design.

- Use of Rogers and polyimide substrates for high-speed signal transmission.

- Differential pair design to reduce crosstalk and improve electromagnetic compatibility (EMC).

- Conformal coating for long-term outdoor stability in high-humidity or high-voltage substations.

Case Study:

Printed circuit board manufacturers offer customized smart grid PCBA solutions that enable stable signal integrity in distributed power systems, supporting the global transition to low-carbon, smart power networks.

4. Renewable Energy PCB Manufacturing Process

The manufacturing process of renewable energy PCBs focuses on sustainability, precision, and environmental responsibility. From material selection to final testing, each stage integrates eco-friendly technologies and clean production principles to minimize the carbon footprint and ensure compliance with global green standards.

(1) PCB Material Selection

- Prioritize lead-free solders, halogen-free solder masks, and eco-friendly copper foil to reduce environmental impact and improve recyclability.

- Use recyclable substrate materials such as FR-4 halogen-free laminates and metal-core PCBs for solar and wind energy applications.

- All materials should comply with RoHS, REACH, and ISO 14001 environmental standards.

(2) Pre-Production: Imaging & Patterning

- Includes cutting, laminating, exposure, and development steps.

- Utilize laser direct imaging (LDI) instead of traditional photolithography to eliminate photoresist film waste and reduce chemical developer usage by up to 30%.

- Optimize panel utilization to minimize raw material waste during PCB panelization.

(3) Inner Layer Circuit Formation

- Employ alkaline etching and micro-etching techniques to remove excess copper precisely.

- Use automated etching lines with closed-loop waste treatment systems to reduce hazardous effluent discharge.

(4) Lamination and Drilling

- Apply multi-layer lamination with precision alignment systems to ensure high-density interconnects for renewable energy converters and inverters.

- Laser and CNC drilling minimize material loss and dust emission, supporting clean-room compliance.

(5) Outer Layer Circuit and Plating

- Perform copper electroplating and pattern plating with advanced automation to achieve uniform thickness.

- Replace tin-lead stripping with lead-free immersion tin or ENIG finishes, reducing heavy metal contamination and improving solderability.

(6) Solder Mask and Surface Finish

- Use halogen-free green solder mask ink, enhancing insulation and UV resistance for outdoor energy systems.

- Apply eco-friendly surface finishes such as ENEPIG or OSP to ensure strong corrosion resistance under harsh environmental conditions.

(7) Profiling, Electrical Testing, and Quality Control

- Adopt precision routing or laser cutting to reduce edge burrs and dust.

- Conduct 100% electrical testing and AOI inspection to ensure reliability for solar power converters, EV charging stations, and battery management systems.

- Implement waste segregation and recycling systems to recover copper and other metals efficiently.

5. Moving Toward Green Energy PCBs and Sustainable Manufacturing

As sustainability becomes a global priority, the PCB assembly and manufacturing industry is rapidly transforming toward eco-friendly materials, energy-efficient manufacturing, and circular production systems.

Modern PCB manufacturers play a crucial role in supporting this green transition, adopting advanced technologies and environmentally responsible practices to reduce their carbon footprint and enhance product reliability.

(1)PCB Material Innovation: Eco-Friendly and Lead-Free

The foundation of sustainable PCB board fabrication lies in green material selection.

- Lead-free solder and halogen-free laminates replace traditional toxic substances, ensuring compliance with RoHS and REACH standards.

- Plant-based copper-clad laminates (CCL) and ultra-thin flexible substrates reduce overall material consumption while maintaining high electrical performance.

- Recyclable metal-core PCBs (MCPCBs) are increasingly used in solar panels, EV chargers, and wind energy converters, improving heat dissipation and lifespan.

According to industry research, switching to halogen-free materials can reduce printed circuit board production CO₂ emissions by up to 27% compared to conventional processes.

(2) Process Upgrade: Cleaner and Smarter Manufacturing

- Eco-conscious manufacturers are embracing green process innovations that minimize environmental impact throughout production:

- Water-based cleaning systems replace solvent-based methods, lowering VOC (volatile organic compound) emissions by over 40%.

- Eco-friendly etching solutions and closed-loop chemical recovery systems significantly cut hazardous waste generation.

- No-clean flux technology reduces post-assembly chemical residues, enhancing production efficiency and reliability.

- Renewable energy integration — solar-powered SMT lines and smart energy management systems — further reduce electricity consumption in PCB fabrication.

These process optimizations not only reduce waste but also improve yield stability and enhance long-term reliability of renewable energy PCB assemblies.

(3) Circular Utilization: Recycling and Resource Efficiency

Circular economy principles are reshaping PCB board production:

- Etching solution recycling systems enable copper recovery rates exceeding 98%, transforming waste into reusable raw materials.

- Scrap circuit board recycling converts residual boards into reclaimed fiberglass and metal resources.

- Participation in carbon trading programs provides measurable financial and environmental benefits, aligning with ESG and ISO 14001 sustainability goals.

Companies implementing closed-loop recycling have reported up to 20% reduction in raw material procurement costs while achieving zero-waste certification.

The transition to green energy circuit design represents not only a technological upgrade but also a strategic commitment to sustainability.

By integrating environmental compliance, clean production, and material recycling, PCB assembly manufacturers are leading the global move toward sustainable electronics — supporting the next generation of renewable energy innovation.

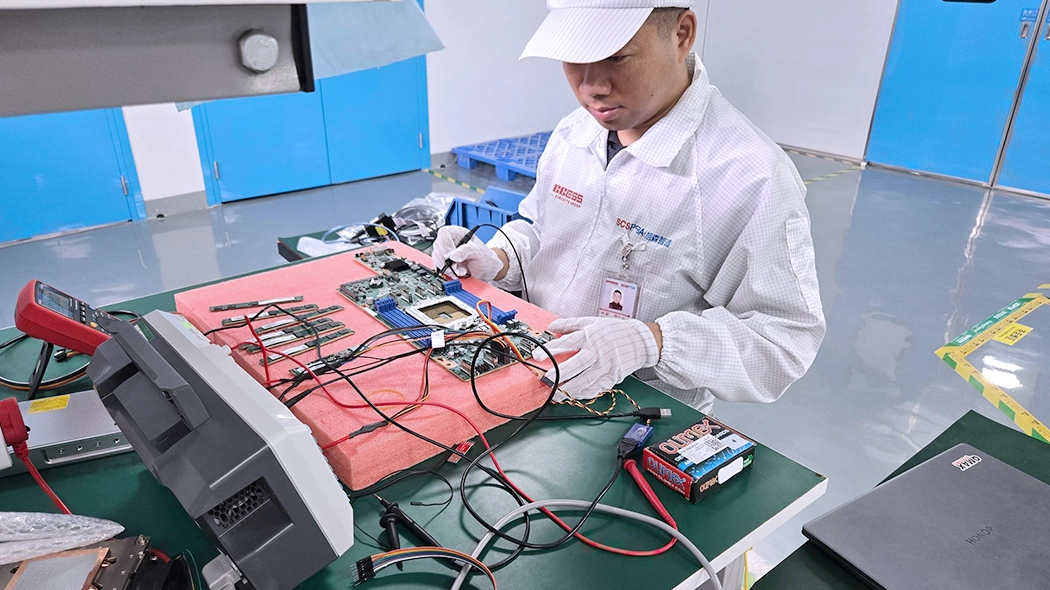

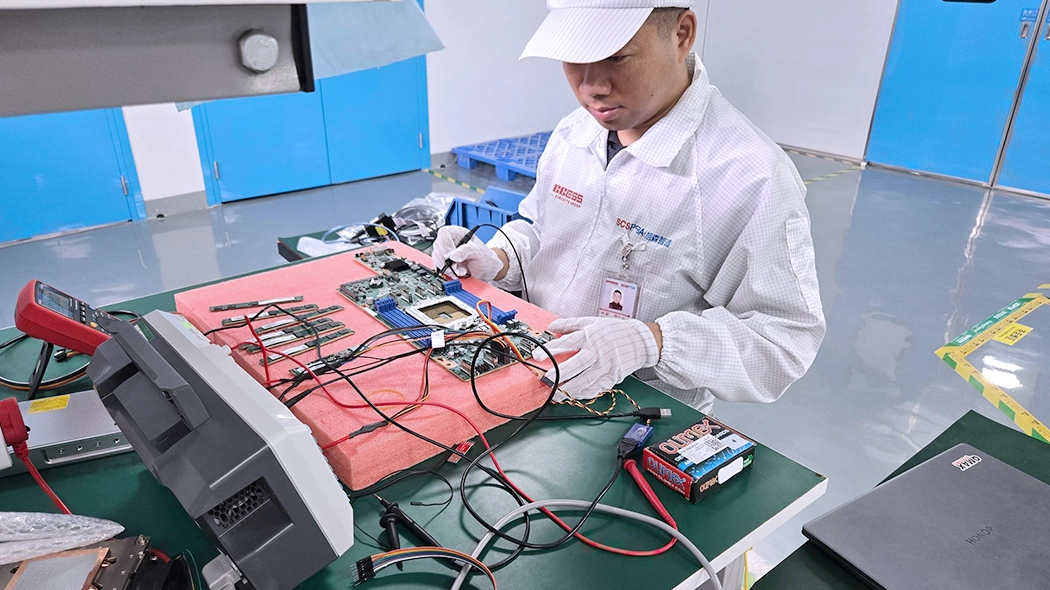

6. Manufacturer of Renewable Energy PCB Assembly

With over 12 years of expertise in PCB and PCBA manufacturing, SCSPCBA provides end-to-end renewable energy PCB assembly services. Our one-stop PCBA solutions combine precision engineering, reliability testing, and environmental compliance, ensuring every energy system operates efficiently and sustainably in demanding field environments.

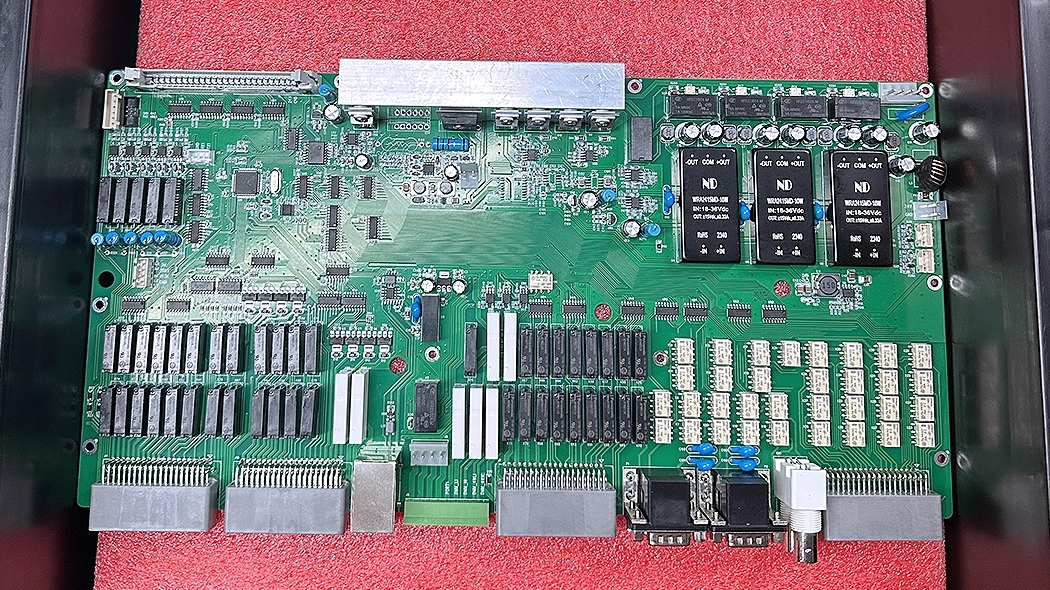

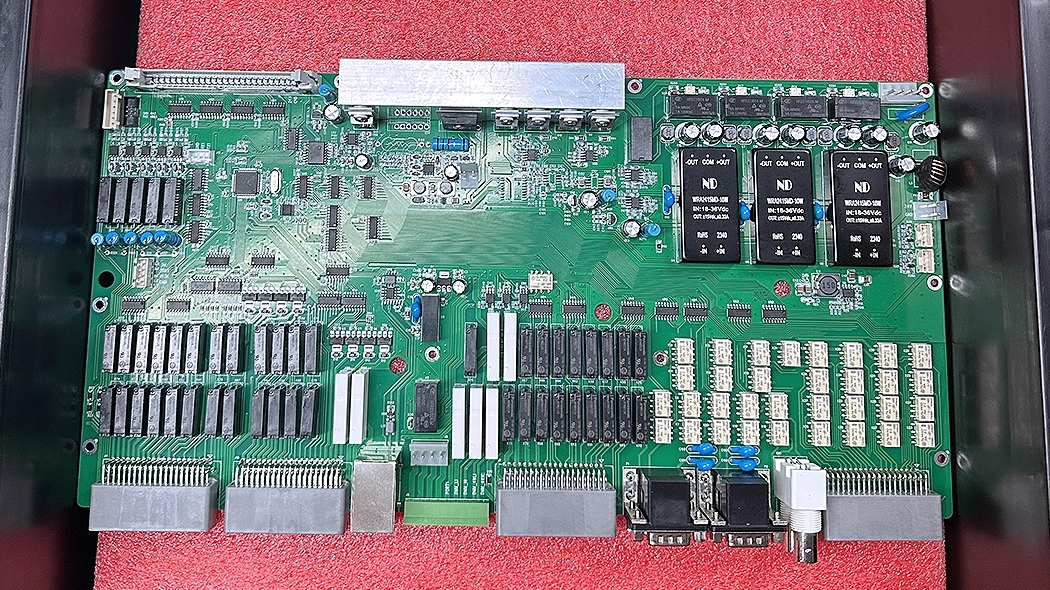

(1) Advanced PCB Assembly Capabilities

SCSPCBA offers a comprehensive manufacturing process, covering every stage from design review and SMT assembly to wave soldering and functional testing — providing customers with a single, integrated supply chain for energy electronics manufacturing.

Our advanced SMT lines are equipped with:

- Yamaha YSM20R pick-and-place machines, offering placement accuracy of ±0.025 mm for high-density energy modules.

- 10-zone nitrogen reflow ovens, maintaining precise peak temperatures of 245–260 °C to ensure strong solder joints for high-current applications.

- Automated Optical Inspection (AOI) and X-ray testing systems, guaranteeing a defect rate below 0.001% across all PCBA runs.

(2) Engineering Excellence and Process Reliability

Key advantages include:

- High-density multilayer and HDI designs for precise power control.

- Enhanced heat dissipation using thick copper and metal-core substrates.

- Strict quality management under ISO 9001 and IATF 16949 systems to meet global green energy standards.

SCSPCBA maintains a first-pass yield exceeding 99.98%, ensuring customers benefit from both efficiency and reliability.

(3) Why Choose SCSPCBA for Green Energy PCB Assembly

As renewable energy systems evolve toward higher efficiency and smarter control, SCSPCBA stands out as a trusted manufacturing partner delivering innovation, quality, and sustainability.

Key advantages include:

- End-to-end PCBA production — from DFM optimization, SMT, and wave soldering to functional and reliability testing.

- Material and process excellence — using halogen-free laminates, lead-free solder, and eco-friendly copper foils.

- Comprehensive testing — ensuring stable operation in high-temperature, high-current, and outdoor environments.

- Collaborative engineering support — enabling rapid prototyping and scalable mass production for solar, wind, and energy storage markets.

SCSPCBA not only delivers precision and performance but also aligns with the principles of green energy PCB manufacturing, supporting a sustainable electronics ecosystem.

7. FAQs: Renewable Energy PCB Assembly

Q: What types of PCBs are used in renewable energy systems?

A: Renewable energy applications often use thick-copper, aluminum-base, or multilayer PCBs to handle high voltage and current. SCSPCBA provides custom PCB solutions for solar inverters, battery management, and wind power electronics.

Q: How does SCSPCBA ensure reliability in high-temperature applications?

A:We use high-Tg FR-4 (≥ 170 °C) materials, nitrogen reflow soldering, and thermal-cycle testing to ensure stability under long-term high-temperature conditions.

Q: What certifications support SCSPCBA’s energy PCB production?

A:Our facilities are ISO 9001, ISO 14001, and IATF 16949 certified, following IPC-A-610 and UL standards for high-reliability assemblies.

Q: Can SCSPCBA handle low-volume, high-mix renewable energy projects?

A: Yes. We offer flexible SMT lines suitable for small-batch or prototype builds while maintaining industrial-grade precision and traceability.

8. Ready to build reliable energy electronics with SCSPCBA?

Whether you’re developing solar inverters, energy storage systems, or electric vehicle power modules, SCSPCBA offers customized PCB assembly solutions to meet your performance and reliability goals.Contact us today for a detailed quote or technical consultation on renewable energy PCB assembly solutions.