Industrial Control PCB Assembly: Reliable PCBA Solutions for Industrial Control

1. Industrial Control PCBA: The Core of Reliable Automation Systems

Industrial control printed circuit board assembly carries and implements crucial functions such as signal sensing, data processing, logical decision-making, and instruction execution in industrial automation systems. Specifically, this is reflected in the following aspects:

(1) As the Physical Carrier of The Control System

Industrial control PCBA is the hardware foundation of core control equipment such as PLCs (Programmable Logic Controllers), DCS (Distributed Control Systems), servo drives, and human-machine interfaces (HMI). It provides a physical mounting platform and electrical connection pathways for all electronic components, including microprocessors (MCU/MPU), memory, sensor interfaces, communication chips, and power modules.

(2) Automation Systems Rely on Real-time Data Flow

The circuits on the PCBA receive weak analog signals from sensors such as temperature, pressure, and position, and preprocess them through amplification, filtering, and isolation (such as using optocouplers) to eliminate electromagnetic interference in the industrial environment.

(3) Ensuring System Reliability and Stability in Harsh Environments

Industrial control PCBAs must be designed and manufactured using more durable materials and stricter process standards to withstand harsh industrial environments such as high and low temperatures, humidity, dust, vibration, and strong electromagnetic interference.

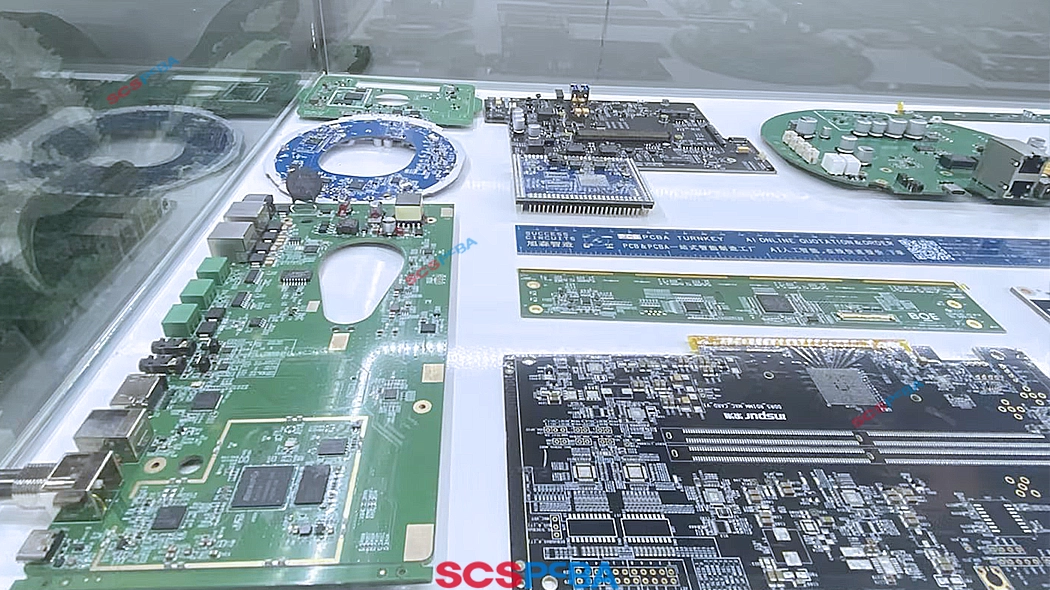

2. Industrial Control PCBA Application Scenarios

Industrial control PCBA is widely used in:

(1) Programmable Logic Controllers (PLCs)

PLCs are the brains of industrial automation, and their core is highly reliable PCB assembly and manufacturing. These circuit boards are responsible for receiving signals from sensors, executing preset logic programs, and outputting control commands to actuators such as motors and valves, thereby achieving automated control of production lines and machinery.

(2) Industrial Sensors and Measuring Instruments

Whether monitoring temperature, pressure, flow rate, liquid level, or other physical parameters, industrial sensors and measuring instruments rely on precise PCB fabrication and assembly to collect weak analog signals, amplify them, and perform analog-to-digital conversion, then output or transmit the processed data. These PCB manufacturing assemblies require high precision and resistance to industrial environmental interference.

(3) Industrial Robots

The joint drives, motion control, and sensing systems of industrial robots all rely on assembly boards. They are used to process data from encoders, torque sensors, etc., run complex motion control algorithms, and drive servo motors to achieve precise and coordinated movements.

(4) Motor Drives and Control

In various industrial equipment, from large pumps to precision machine tools, PCBAs are used to build motor drivers and controllers, enabling precise control of motor speed, torque, and position.

(5) Industrial Communication and Network Interfaces

PCBA manufacturing is used to manufacture communication devices such as industrial Ethernet switches and fieldbus gateways (e.g., Profibus, Modbus), ensuring stable and real-time transmission of control signals and data in the factory network.

(6) Human-Machine Interfaces (HMIs) and Control Panels

The touch screens, control panels, and operator consoles used by factory operators all contain circuit board assemblies, which are used to process user input, display operating status and alarm information, and communicate with the higher-level control system.

3. Stability and Anti-Interference: Core Requirements of Industrial PCBA

Industrial control boards face strong electromagnetic interference (EMI) and unstable power environments. Key requirements include:

- Multi-layer PCB with optimized grounding and power planes

- Strict impedance control and signal integrity design

- EMI/ESD protection layout and component placement

- High-temperature, long-life industrial-grade components

A single unstable solder joint or layout flaw can cause system downtime, making high-reliability industrial printed circuit board assembly manufacturing essential.

4. Industrial-Grade PCBA Manufacturing Configuration at SCSPCBA

(1) High-Reliability SMT Lines for Industrial Control PCBA Manufacturing

SCSPCBA operates 5 SMT production lines, specifically configured to support industrial control PCBA, automotive electronics, and medical electronics—not just consumer products.

☆ High-End Multi-Function SMT Line (2+1 Configuration) – 1 Line

- This line is dedicated to high-reliability applications, including:

- Industrial control PCBA

- Automotive electronics

- Medical electronics

- Communication equipment

- Key advantages for industrial PCB assembly:

- Supports high-mix, high-density, multi-layer PCB

- Suitable for fine-pitch BGA, QFN, and complex IC packages

- Stable process control for long-life industrial products

- Ideal for anti-interference and high-consistency automation PCB assembly

This SMT line is where industrial-grade PCBA requirements are truly met, rather than adapted from consumer production.

☆ Standard SMT Lines (1+1 Configuration) – 3 Lines

Primarily used for consumer electronics, these lines are strictly isolated from industrial control projects.

Industrial control PCBA is not mixed with high-speed consumer orders, ensuring:

- Stable process parameters

- Reduced changeover risk

- Better quality consistency

☆ Dedicated Sample SMT Line – 1 Line

Designed for:

- Industrial control PCBA prototypes

- Engineering samples

- Small-batch trial production

This allows OEM & ODM customers to move smoothly from prototype → pilot → mass production without changing manufacturing logic.

☆ SMT Production Capacity

- 40,000,000/point/day

High capacity ensures:

Stable delivery for long-term industrial PCBA projects

Scalability for automation customers entering mass circuit board manufacturing production

(2) Industrial-Focused DIP Assembly Capability

Industrial control boards often include power components, connectors, relays, transformers, which require reliable through-hole assembly.

SCSPCBA provides 2 DIP production lines, optimized for industrial reliability.

☆ Selective Soldering Line – 1 Line

Dedicated to small-batch, high-reliability orders, including:

- Industrial control PCBA

- Automotive electronics

- Medical electronics

Advantages for industrial PCBA:

- Precise soldering for mixed SMT + DIP boards

- Reduced thermal stress on sensitive components

- Higher solder joint consistency than wave soldering

This is especially important for PLC boards, control modules, and power control PCB board production.

☆ Wave Soldering Lines – 2 Lines

Mainly used for:

- Consumer electronics

- Large-volume standardized products

Industrial projects are selectively assigned, avoiding unnecessary printed circuit board manufacturing process risk.

☆ Manual Soldering Lines – 2 Lines (8 Skilled Operators)

Used for:

- Industrial samples

- Small-batch control boards

- Customized or non-standard components

Manual soldering is controlled, documented, and inspected—not used as a shortcut, but as a precision supplement for industrial control PCBA.

☆ DIP Production Capacity

- 350,000 solder joints per day

Ensures reliability without sacrificing delivery time.

(3) Assembly & Testing Lines for Industrial Control Systems

SCSPCBA operates 2 dedicated assembly & testing lines, essential for industrial control products that require functional validation, not just visual inspection.

☆ Testing Capability

6 functional test stations supports:

- Power-on testing

- Signal verification

- Load simulation

- Custom test fixtures

Functional testing is critical for industrial PCB assembly, where field failure is unacceptable.

☆ Final Assembly Capability

20 assembly workstations supports:

- Control box assembly

- Cable & connector integration

- Industrial enclosure assembly

This enables PCBA + box build services for automation and industrial control systems.

(4) Manufacturing Efficiency Reflects Industrial Maturity

SCSPCBA’s manufacturing data demonstrates process maturity, not labor dependency.

- Annual production value: 1.6 million (pure PCBA processing)

- Per capita production value: 20,000

This indicates:

- High automation level

- Stable process control

- Lower human error rate

For industrial control PCBA, process stability is more important than sheer labor scale

5. DFM Advantage: Reducing Risk Before Production

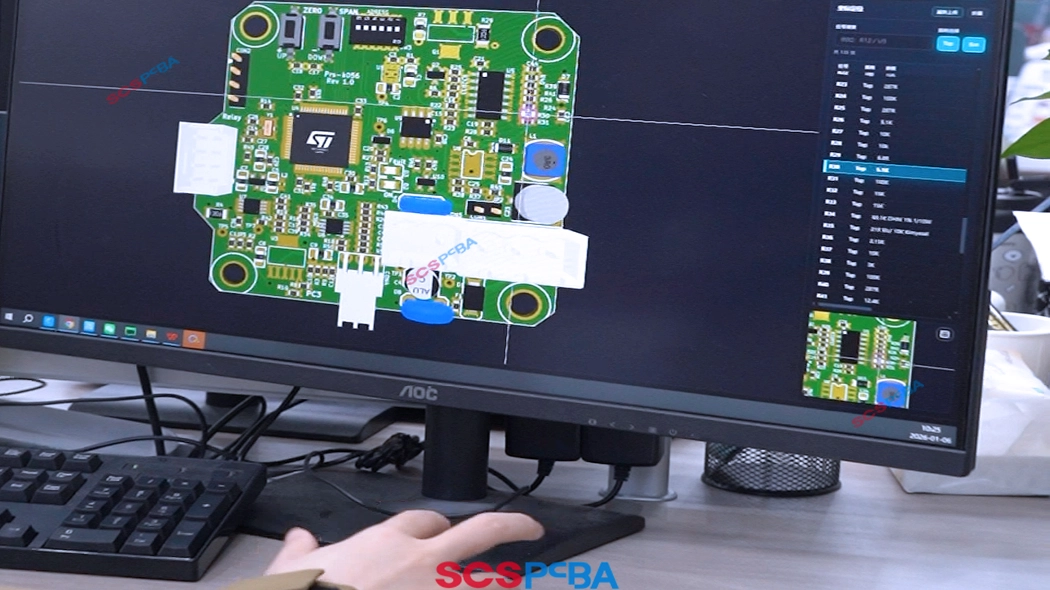

At SCSPCBA, DFM is implemented as a manufacturing-driven design optimization system, ensuring that potential risks are identified and eliminated before mass pcb assembly production begins.

SCSPCBA DFM System for Industrial Control PCBA

SCSPCBA provides a structured DFM analysis workflow, specifically tailored for industrial PCB assembly and automation PCBA, covering the following critical dimensions

(1) PCB Stack-Up & Material Optimization

Industrial control PCBA often operates in environments with electrical noise, thermal stress, and long duty cycles.

SCSPCBA evaluates:

- PCB layer stack-up structure

- Copper thickness and dielectric material selection

- Signal, power, and ground plane distribution

- Impedance consistency and EMC considerations

Improved signal integrity, reduced EMI risk, and enhanced long-term stability for industrial control PCB assembly.

(2) Pad Design & Soldering Reliability Checks

Solder joint reliability is a crucial factor in automation PCB assembly, particularly for applications that are prone to vibration and require high current.

DFM checks include:

- Pad size, shape, and symmetry verification

- Fine-pitch BGA / QFN solder joint reliability analysis

- Mixed SMT + THT process compatibility

- Solder fillet quality and thermal balance assessment

Lower risk of cold solder joints, tombstoning, voiding, and long-term fatigue failure.

(3) Thermal Design & Heat Dissipation Optimization

Thermal issues are one of the most common root causes of industrial electronics failure.

SCSPCBA’s DFM system analyzes:

- High-power component placement

- Copper pour and thermal via design

- Heat flow paths across PCB layers

Compatibility with enclosure-level heat dissipation

(4) BOM Risk Analysis & Component Strategy

Industrial projects often require long lifecycle support and supply chain stability.

SCSPCBA performs:

- BOM completeness and consistency checks

- Lifecycle and EOL (End-of-Life) risk assessment

- Alternative component validation

- Cost-performance optimization without reliability compromise

Reduced supply chain disruption risk and improved cost control for industrial PCB fabrication and assembly projects.

(5) Why DFM Matters for Industrial Control PCB Assembly

Unlike factories that address issues during production, SCSPCBA applies a DFM-first approach, where:

- Engineering feedback precedes tooling and SMT programming

- Design risks are corrected before volume scaling

- Manufacturing feasibility is validated upfront

This approach significantly reduces:

- Production rework

- Yield loss

- Field failure and after-sales risk

6. MES System: Full Traceability for Industrial Control PCBA

SCSPCBA’s MES system enables:

Component batch-level traceability

Real-time production data monitoring

Process parameter recording for each PCB fabrication process

Quality history tracking for audits and after-sales support

This is especially critical for OEM and ODM industrial PCBA projects

7. Industrial Control PCBA Online Quotation

(1) How the Industrial PCBA Online Quotation System Works

To start an industrial PCB assembly quotation, customers simply upload:

- PCB File – for PCB structure, layer stack-up, and process evaluation

- BOM list – for component sourcing, lifecycle assessment, and cost analysis

- Assembly File – assembly soldering, surface mount pcb assembly, soldering assembly, reflow soldering

Based on these file and list, the system generates a fast and transparent preliminary quotation covering:

- PCB board fabrication

- SMT assembly

- Through-hole (DIP / selective soldering)

- Functional testing

- Optional box build and final assembly services

This enables OEM and ODM customers to quickly evaluate project feasibility and budget.

(2) Why Online Quotation Is Reliable for Industrial Control PCBA

SCSPCBA’s quotation system is built on actual industrial manufacturing data, including:

- SMT and DIP line capabilities

- Process time and testing workload

- Quality control and traceability requirements

- Engineering support and DFM involvement

As a result, customers receive:

- Realistic pricing

- Predictable lead time

- Fewer changes during production

This is critical for industrial PCB assembly and automation PCB projects, where late-stage changes create high risk and cost.

(3) Supporting OEM & ODM Industrial Control PCBA Projects

The PCBA online quotation system is particularly valuable for:

- OEM customers evaluating new industrial control products

- ODM customers comparing manufacturing strategies

- Automation companies scaling from prototype to mass production

Combined with SCSPCBA’s DFM and MES systems, the quotation process becomes part of a controlled and traceable manufacturing workflow.

If you are planning an industrial control PCBA or automation PCB assembly project, SCSPCBA’s online quotation system provides a fast, transparent, and engineering-backed starting point.

8. How OEM & ODM Customers Choose Industrial Control Printed Circuit Manufacturing

For OEM and ODM clients, the right partner should offer:

- Proven industrial PCBA experience

- Strong DFM and engineering support

- Stable supply chain and MES system

- Scalable production capacity

SCSPCBA supports OEM and ODM industrial control PCBA from prototype to mass production, helping customers shorten time-to-market while maintaining quality.

9. Industrial Control PCBA Case Sharing: From Online Quotation to Stable Mass Production

An industrial automation manufacturer (OEM) uses products for factory control systems that operate in high-interference and high-load environments for a long time and have extremely high requirements for stability, maintainability and consistency of equipment.

(1) Customers Use SCSPCBA Industrial PCBA Online Quotation System

The customer uploaded the following files through SCSPCBA’s Industrial Control PCBA Online Quotation System:

- PCB File(Gerber)

- BOM List

- Assembly File

The system quickly generated a preliminary quotation for Industrial PCB Assembly, covering:

- PCB manufacturing

- SMT placement

- THT / DIP process

- Function test

(2) Use DFM Analysis System

Before confirming manufacturing of the industrial control PCBA board, the SCSPCBA engineering team initiated a DFM (Design for Manufacturability) analysis based on the customer documentation.

DFM focuses on discovering and optimizing the following issues:

- PCB stack-up and grounding structure:

Optimize power and ground plane layout to reduce EMI risks in industrial environments - Key device pad design:

Adjust the pads of some high-power and interface devices to improve welding reliability - Thermal design issues:

Optimize copper foil laying and heat dissipation paths for control boards that continue to work

(3) The MES System Ensures Traceability of Industrial Control PCBA Manufacturing

PCBA enters the later stage of production, and SCPCBA’s MES monitors the entire process.

The MES system implemented in this industrial control PCBA project:

- Missing batch level supplement

- SMT/DIP Problem Parameter Logging

- Test data binding for each PCBA

- Production exceptions can be traced back and quickly positioned

(4) Industrial Control Grade PCBA Project Results

One-off small batch production

The functional test pass rate is significantly higher than the customer’s previous projects

No on-site abnormalities caused by manufacturing issues

Smoothly enter the subsequent mass production stage

Customer feedback:

“SCPCBA’s online quotation is not a simple price calculation, but takes engineering, manufacturing and risk control into consideration, which is very critical for industrial control PCBA.”

If you are developing or upgrading industrial control PCBA/automated PCB assembly projects:

Upload your PCB file + BOM list + assembly file

9. Industrial control PCBA FAQ

How is industrial control PCBA different from consumer PCB assembly?

Industrial PCB assembly focuses on stability, anti-interference, long lifecycle components, and strict process control, while consumer PCBA prioritizes cost and speed.

What industries typically use industrial control PCBA?

Industrial control PCBA is widely used in:

- Factory automation

- Robotics and motion control

- Energy and power systems

- Industrial communication equipment

- Smart manufacturing and MES-connected devices

What reliability requirements are critical for industrial PCB assembly?

Key requirements include:

- Strong EMI/ESD resistance

- Stable power and signal integrity

- High solder joint reliability

- Continuous operation under harsh environments

What PCB types are commonly used in industrial control systems?

Common types include:

- Multi-layer control boards

- Power control PCBA

- PLC main boards

- Signal acquisition and processing boards

- Industrial communication boards

What does SCSPCBA’s DFM system cover?

SCSPCBA’s DFM system includes:

- PCB stack-up and material evaluation

- Pad design and soldering reliability checks

- Thermal design optimization

- BOM risk analysis and alternative component suggestions

Can SCSPCBA support small-batch and prototype industrial PCBA?

Yes. SCSPCBA supports prototypes, pilot runs, and scalable mass production, allowing OEM and ODM customers to grow without changing suppliers.

What testing is required for industrial control PCBA?

Typical testing includes:

- AOI and X-Ray inspection

- ICT testing

- Functional testing under load

- Customized test fixtures for control systems

Does SCSPCBA provide industrial control PCBA online quotation?

Yes. SCSPCBA offers an industrial PCBA online quote system for fast and transparent pricing based on Gerber files, BOM, and assembly data.

Can SCSPCBA support OEM and ODM industrial control projects?

Absolutely. SCSPCBA supports both OEM and ODM industrial PCBA, offering DFM support, supply chain management, testing, and optional box build services.

Is online quotation reliable for industrial PCB assembly projects?

Yes. All industrial quotations are reviewed by engineers after system pricing, ensuring manufacturability, reliability, and realistic lead times.