PCB Assembly Prototype to Mass Production: How Volume Impacts Cost, Risk & Quality

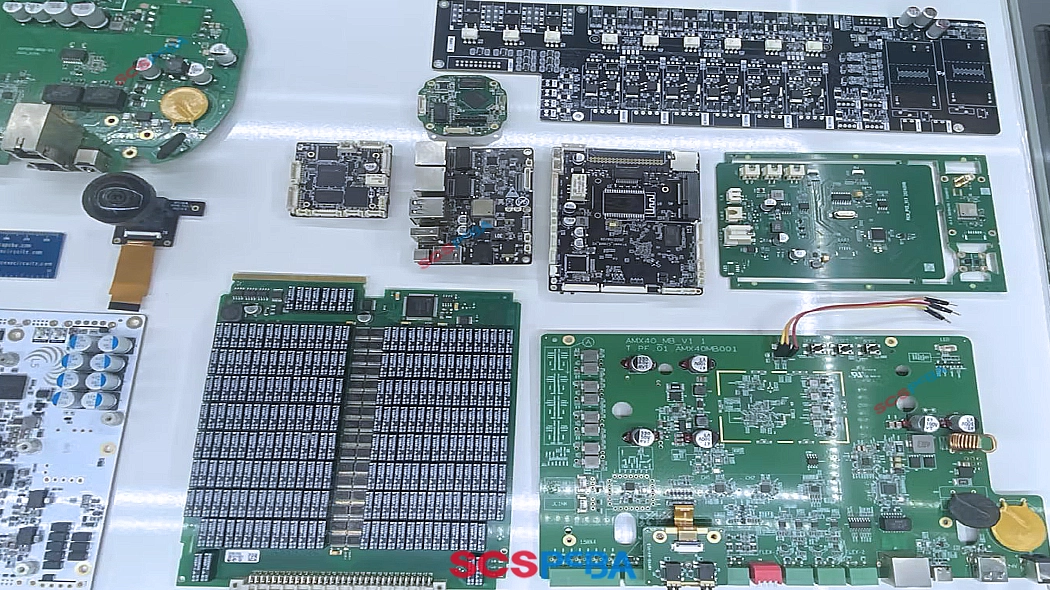

1. Why PCB Assembly Volume Matters for ODM/OEM

When evaluating PCB projects, ODM/OEM purchasing teams consider PCB assembly volume to assess the stability and overall cost-effectiveness of the printed circuit board assembly manufacturer supply chain.

(1) Direct Impact of PCB Assembly Quantity on Cost

Unit cost decreases significantly with batch size

- There is a clear scale effect in the procurement of bare PCB boards and components. Fixed costs such as production preparation and engineering expenses (e.g., stencil fabrication, programming) are significantly diluted in large-volume orders.

- For example, the unit price of a small-volume pcb board fabrication order (<100 pieces) may be 30%-50% higher than that of a large-volume order of 5000 pieces or more.

Increased PCB material utilization

- Mass production typically uses panelization, integrating multiple boards into a single processing unit, significantly improving substrate utilization and reducing edge waste.

- Data shows that panelization can increase circuit board material utilization from 60% to over 80%, directly reducing substrate costs by 15%-20%.

Enhanced bargaining power in circuit board components procurement

- The larger the assembly volume, the more bargaining power the PCBA manufacturers have in procuring electronic components (e.g., chips, capacitors), especially for key components (e.g., MCUs, FPGAs), where bulk discounts can be obtained, with reductions reaching 30%-50%.

(2) Impact on Delivery Cycle

Small batch PCB board production leads to longer delivery times

- Due to frequent production line changes and high preparation time, preparation time for small batch PCB production can account for more than 30% of the total cycle, resulting in longer delivery times per unit.

Large batch production has higher priority

- PCBA maufacturer factories tend to allocate resources to large batch orders because of their high equipment utilization and low management costs, thus ensuring delivery stability.

(3) PCB Quality and Production Stability

Paneling improves circuit board manufacturing process consistency

- In panelization mode, processes such as SMT placement and reflow soldering are centrally processed, reducing human intervention.

- AOI inspection data shows that the circuit defect rate of panelized production (0.3%) is much lower than that of single-board production (1.2%).

High risk of quality fluctuations in small batch production

- The high proportion of first-article inspection and the large sample size for process control result in quality inspection time being 1.5-2 times that of large batch production, and the cost of reworking defective products is also higher.

2. What Is Prototype, Low, Medium & High Volume PCB Assembly?

(1) Prototype PCB Assembly

Quantity Range: Typically 1-10 pieces, mainly used for design verification and functional testing

Core Purpose: To verify the circuit logic, layout and routing rationality, and basic functional feasibility; a critical step in the early stages of R&D.

Features:

- Fast delivery; PCB manufacturers offer “expedited prototyping” services, with shipments as fast as 24 hours.

- Not focused on cost optimization; unit price is relatively high, but very small minimum order quantities (e.g., 5 pieces) are supported.

- Processes may be simplified in some areas (e.g., manual soldering, non-fully automated placement) to shorten the cycle time.

(2) Small Batch PCB Assembly

Quantity Range: 50-1000 pieces, with slight variations among printed circuit board assembly manufacturers.

Typical Uses: Customer sampling, market testing, pilot testing, small-batch trial sales.

Features:

- Costs are significantly lower than in the printed circuit board prototype stage, and economies of scale are beginning to emerge.

- High requirements for circuit board manufacturing processes, especially in industrial control, medical, and automotive electronics fields.

- Frequent production line switchovers and reliance on flexible production capabilities.

- Quality control must be on par with large-batch production; raw material inspection and AOI testing are indispensable processes.

(3) Medium Batch Printed Circuit Board Assembly

Quantity Range: 1000~10000 pieces/year, or approximately 50~200㎡ in area.

Application Scenarios: When products enter the initial market promotion stage, or for bulk supply to small and medium-sized customers.

Features:

- Enjoy better material utilization and component procurement discounts.

- PCB board production becomes more stable, and semi-automated or fully automated placement lines can be used to improve consistency.

- Delivery time is more controllable than small batch

(4) Mass PCB Manufacturing and Assembly

Quantity Range: single orders exceeding 5,000 pieces; some printed circuit board assembly companies define mass production as orders exceeding 50,000 pieces. Annual production of 10,000 to 100,000 pieces also falls into this category.

Typical Scenarios: Mass production of mature products and large-scale market distribution (e.g., consumer electronics).

Features:

- Lowest unit cost; fixed costs (e.g., stencils, programming) are fully amortized.

- Wide application of panel design; circuit board materials utilization rate can reach over 80%

- Uses fully automated SMT lines control to ensure consistent quality.

The definition of “small batch” and “large batch” varies depending on the size of the PCB assembly manufacturer and the industry.

3. Why Many Printed Circuit Assembly Corporations Avoid Small-Batch and Mixed-Batch Orders

Small-batch orders are the starting point for product innovation and trial production. Still, for PCB assembly corporations, they have higher fixed costs, lower production efficiency, and require significantly more resources than large-batch orders, as detailed below:

(1) Fixed costs are difficult to amortize, resulting in high unit price pressure

The initial investment in PCB assembly (such as stencil fabrication, SMT program debugging, and DFM analysis) is a fixed cost that will not decrease with reduced order volume.

- A set of custom stencils costs approximately 300-500 yuan. If used for a small batch order of only 10 pieces, the cost per piece is as high as 30-50 yuan; while for an order of 1000 pieces, the cost per piece is only 0.3-0.5 yuan.

The preparation time for engineering debugging, first article inspection, etc., is almost the same as for large orders. Still, the output is extremely low, resulting in abnormally high unit circuit board assembly costs.

(2) Frequent line changes reduce production line efficiency

Surface-mount technology production lines require continuity and stability.

Small-batch surface-mount assembly orders are diverse and few in quantity, leading to multiple line changes daily: stencil replacement, placement program adjustments, vision system calibration, reloading, etc. Each SMT line changeover takes 30 minutes to several hours.

During line changeovers, equipment idles, capacity is idle, and the frequency of first article confirmation and in-process sampling inspections needs to be increased.

(3) Complex Material Management

Mixed batch orders mean multiple BOMs running concurrently, resulting in dispersed material requirements:

Small-batch purchases cannot enjoy centralized procurement discounts, and component unit prices are higher; for example, the price of a small-batch capacitor purchase may be more than 50% higher than that of a large-batch purchase.

Customized materials are difficult to standardize, easily leading to inventory backlogs or shortages. Low completeness rates result in production delays and extended delivery cycles.

Material traceability and management costs increase, especially when multiple projects are running concurrently, significantly increasing the risk of errors.

The Response Strategy of Professional SCSPCBA Manufacturers: Not Rejection, but Optimized Acceptance

Despite the challenges, SCSPCBA actively accepts small-batch orders, viewing them as a starting point for testing technical capabilities and building customer relationships.

- Establishing Independent Rapid Prototyping Lines

Equipped with multi-skilled workers and general-purpose equipment; - Establishing a Shared Materials Library

Stocking commonly used components to shorten kitting time; - Introducing Digital Systems ——MES Systems

Implementing rapid quoting, intelligent scheduling, and end-to-end traceability; - Providing Value-Added Services

DFM optimization and alternative material suggestions; - Providing an Online Quotation Platform

Supporting 24/7 online order placement.

4. SCSPCBA Supports Prototype & Small Batch & Medium Batch to Large Batch Production

(1) Online PCBA Quotation System

SCSPCBA’s online quotation system is not just for price calculation; rather, its quotation logic from PCB prototype to mass circuit board production is predictable, comparable, and reusable.

- Automatic identification of cost structure differences between samples, small batches, medium batches, and large batches

- Automatic adjustment based on batch size:

- Electronic circuit board components procurement strategy

- Test coverage ratio (AOI/ICT/FCT)

- Printed circuit board production line configuration

(2)Bill of Materials (BOM) Management

SCSPCBA employs a BOM data management mechanism—strict BOM management is used throughout the entire printed circuit board production lifecycle.

PCB material validated in small batches can be directly applied to large-scale production.

This reduces the risk of PCB manufacturing process revalidation due to supply chain changes.

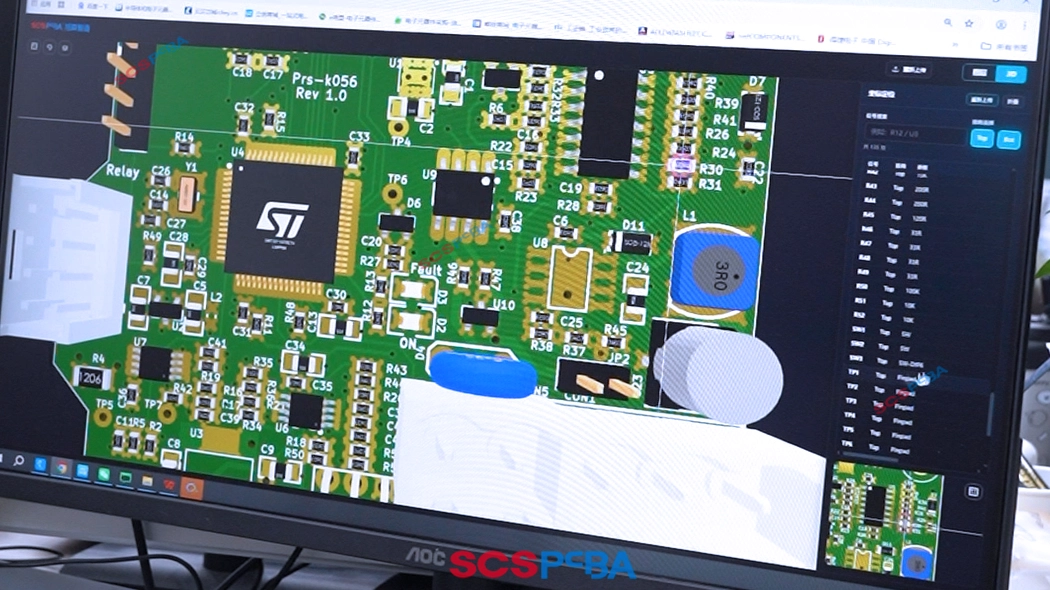

(3) Design for Manufacturability (DFM) Review During PCB Prototyping

Unlike many factories that only conduct DFM during mass production, SCSPCBA performs a complete DFM review during the prototyping stage, covering:

- Pad design and device package compatibility

- Panel layout and automation compatibility

- SMT/DIP process windows

- Test point accessibility

- Future ICT/FCT fixture feasibility

(4) MES Traceability System

SCSPCBA’s MES system is enabled in the prototype stage:

- Single board-level serial number binding

- Association with BOM version, process parameters, and equipment data

- Support for defect traceability to:

- SMT line

- Critical PCB fabrication process node

5. Quality & Process Control That Scales with Volume

In PCB assembly, effective quality control does not mean applying the same inspection intensity to every order.

At SCSPCBA, quality control is volume-adjusted, not volume-compromised.

The inspection and testing strategy is dynamically aligned with:

- PCB board production volume

- Product application risk

- PCB production process maturity level

This approach ensures engineering relevance, cost efficiency, and process stability at every stage—from prototype to high-volume production.

(1) Fast Turn Prototype PCB Board Stage: 100% Visual Inspection + AOI

During the prototype fabrication phase, the primary objective is PCB design and process verification.

- Component placement accuracy

- Solder joint integrity

- Polarity and footprint validation

- 100% manual visual inspection by trained QC engineers

- 100% AOI inspection after reflow

- Early identification of DFM and soldering risks

- Immediate feedback to design and process engineering

- Prevention of design errors being replicated in later stages

(2) Low Volume PCB Production: AOI + Sample Functional Testing

In low volume PCB assembly, the process parameters are largely defined but still under validation.

- Surface mount technology process repeatability

- Early detection of functional anomalies

- 100% AOI inspection

- Sample-based functional testing, defined by product risk level

- Validation of functional performance without excessive test fixture cost

- Confirmation that printed circuit board prototype performance translates to repeatable production output

(3) Medium Volume Production: AOI + Full Functional Testing (FCT)

At medium circuit board prototyping volume, the product enters market-facing production, where failure cost increases significantly.

- Functional stability

- Yield consistency across batches

- 100% AOI inspection

- 100% FCT, simulating real operating conditions

- Detection of latent functional defects not visible optically

- Stabilization of First Pass Yield (FPY)

(4) High Volume Production: AOI + ICT

High volume PCB assembly introduces statistical risk—even low defect rates can result in significant absolute failures.

- Printed circuit board manufacturing process capability

- Long-term consistency

- Cost of quality control

- 100% AOI inspection

- In-Circuit Testing (ICT) for electrical integrity

- Solder paste volume and height

- Placement accuracy

- Reflow temperature profiles

- Key electrical test limits

- Early detection of PCB fab process drift

- Prevention of mass defect propagation

(5) SCSPCBA Monitors Quality Using Industry-recognized, Measurable Indicators:

First Pass Yield (FPY) ≥ 98%

Indicates process stability and effective defect prevention.

Process Capability Index (Cpk) ≥ 1.33

Confirms sufficient process margin for consistent mass production.

Defect Rate < 300 DPPM

Ensures controlled outgoing quality; stricter targets applied for automotive and industrial projects.

These metrics are continuously tracked and reviewed through MES systems to maintain PCBA manufacturing process consistency and long-term reliability.

6. Finished Product Assembly & System Integration

In medium- to high-volume production, box build assembly and system integration achieve a seamless transformation from bare PCB boards to complete, usable products. This process requires high coordination between all stages to ensure that the final delivered circuit board assembly possesses functional integrity, structural stability, and market compliance.

(1) Cable and Connector Assembly

Connectors, acting as “plugs” or “sockets” in circuit systems, provide separable electrical and mechanical connections between the PCB and external devices (such as power supplies, sensors, and displays). By using standard interfaces such as pin headers, RJ45, and USB, they enable efficient and repeatable signal and power transmission. Cable assemblies ensure stable electrical connections within complex devices or across modules.

(2) Housing Installation

The housing not only provides an aesthetically pleasing appearance, but more importantly, it provides physical protection for the internal electronic components, preventing dust, moisture, impacts, and other factors from affecting the product’s lifespan. At the same time, a well-designed structure aids in heat dissipation management and electromagnetic shielding, enhancing overall reliability.

(3) Labeling and Serialization

Each finished product must have a unique identifier (such as a serial number or QR code) for tracking production batches, after-sales service, anti-counterfeiting verification, and meeting industry regulatory requirements (such as in medical and automotive electronics). This process also supports companies in establishing a comprehensive supply chain traceability system.

(4) Final Functional Circuit Test (FCT)

This is the most critical quality control step in the final assembly process. Functional testing simulates the product’s actual operating environment to comprehensively verify whether all functional modules are functioning correctly, including signal transmission, power management, and communication protocol response. Its goal is to detect assembly defects (such as short circuits, poor soldering, and missing components) as early as possible, preventing defective circuit board assembly from flowing into subsequent stages and causing rework and waste.

SCSPCBA’s box build assembly service is an integrated solution built around the above needs, and is particularly suitable for small, medium and high volume orders that require stable delivery and strict quality control.

7. How to Choose the Right PCB Assembly Partner for Each Stage

(1)Prototype PCB Assembly Stage

Pre-production engineer-led DFM (Design for Manufacturing) review

Willingness to communicate design and process risks

Full traceability even in small-batch production

Consistency of process parameters, maintaining alignment with future large-scale production

SCSPCBA supports free stencils for PCB and PCBA orders; all standard templates are provided free of charge; fast delivery and DFM optimization support.

(2) Support Small-batch PCB Assembly Stage

Small-batch PCB assembly often demonstrates the flexibility of PCB assembly manufacturers and their reliance on production volume.

Avoid charging excessive fees unrelated to actual costs.

Support mixed bill of materials procurement and approved alternatives.

Maintain the same quality standards as mass production.

Provide scalable testing solutions instead of mandating the use of high-cost test fixtures.

SCSPCBA can provide cost breakdowns to confirm whether hidden charges (such as stencil fees and debugging fees) are included, ensuring transparency in PCB assembly costs.

(3) Medium Volume PCB Production

Medium volume PCB production is where many projects fail—not due to design, but due to process inconsistency.

Stable First Pass Yield across multiple batches

Defined quality metrics

Minimal engineering change requests caused by manufacturing limitations

Clear production planning and capacity allocation

SCSPCBA has professional SMT placement lines and AOI inspection areas, equipped with key equipment such as pick and place machines, SPI solder paste inspection, and in-circuit functional testing (FCT).

(4) High-volume PCB assembly and manufacturing

High-volume production requires not only capacity but also stringent process flows.

Dedicated production lines or equivalent configurations

Predictable capacity

Component replacement library support

IATF/ISO certification

Continuous process capability monitoring

SCSPCBA establishes a component replacement database and proactively pushes compatible models when stockouts occur, reducing the risk of supply disruptions.