BOM Management in PCB Assembly: Smarter, Faster, and More Reliable with SCSPCBA

In PCB assembly and manufacturing, the Bill of Materials (BOM) is more than just a list of components; it is crucial for ensuring the quality, delivery time, and cost control of printed circuit boards.

Printed circuit assembly corporations face challenges such as opaque component pricing, supplier shortages, difficulties in evaluating alternatives, and low efficiency of manual review, all of which impact PCB board production schedules.

1. PCB Assembly Relies on High-Quality BOM Management

In the Printed Circuit Board assembly process, a high-quality BOM (Bill of Materials) not only includes component numbers, models, packages, quantities, and reference designations, but may also include brand, supplier, alternative material information, and special process requirements.

(1) Precise Guidance for Material Procurement

Due to the increasing complexity of electronic products and intensified supply chain fluctuations, the cycle time of electronic components has become more frequent:

- The lead time for some MCUs has been extended to 36–52 weeks

- The price fluctuation of high-speed interface ICs can reach 20–60%

The BOM provides the purchasing department with clear information on component types, quantities, and suppliers, avoiding omissions and errors in procurement, and ensuring timely and sufficient supply of materials required for production

(2) Support for Production Process Planning

Process engineers arrange the placement, insertion, and soldering sequences based on the BOM, and optimize parameters such as reflow soldering temperature profiles to ensure process compatibility. For mass-produced circuit boards, this can increase production efficiency by 3–6 times.

(3) Ensuring Quality Traceability

If a fault occurs in the circuit board manufacturing process, the brand, batch, and supplier of the problematic component can be traced back through the BOM to quickly pinpoint the root cause.

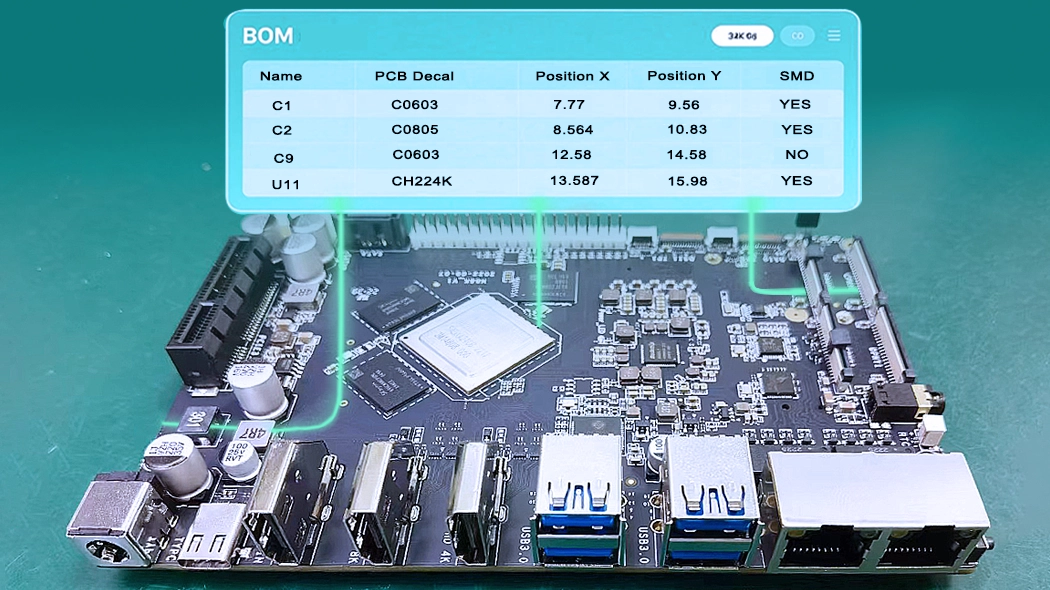

The BOM for a multilayer black printed circuit board includes the name, PCB label, position X , position Y , and SMD components

2. Impact of BOM Management Errors on PCB Assembly

(1) Component Incorrectness

Selecting ICs and components with incompatible packages or incorrect key parameters in the BOM can cause functional abnormalities, leading to crashes, failures, or even burnouts under high temperatures or long-term operation.

These problems typically only surface during the final PCBA testing or customer usage phase, resulting in extremely high rework and after-sales costs.

(2) Inventory Management Imbalance

Inaccurate BOM information can lead to shortages of key components, forcing production line shutdowns; or incorrect usage estimates can result in over-purchasing of components, tying up significant inventory funds and increasing warehousing and financial pressures.

This is particularly prominent in multi-batch, small-volume PCBA projects.

(3) Cost Overruns

Failure to conduct multi-channel price comparisons for components, evaluation of alternative materials, or inaccurate usage calculations can all lead to higher-than-expected procurement costs, resulting in inaccurate PCBA pricing, reduced profit margins, and even impacting long-term customer relationships.

(4) Potential Quality Issues

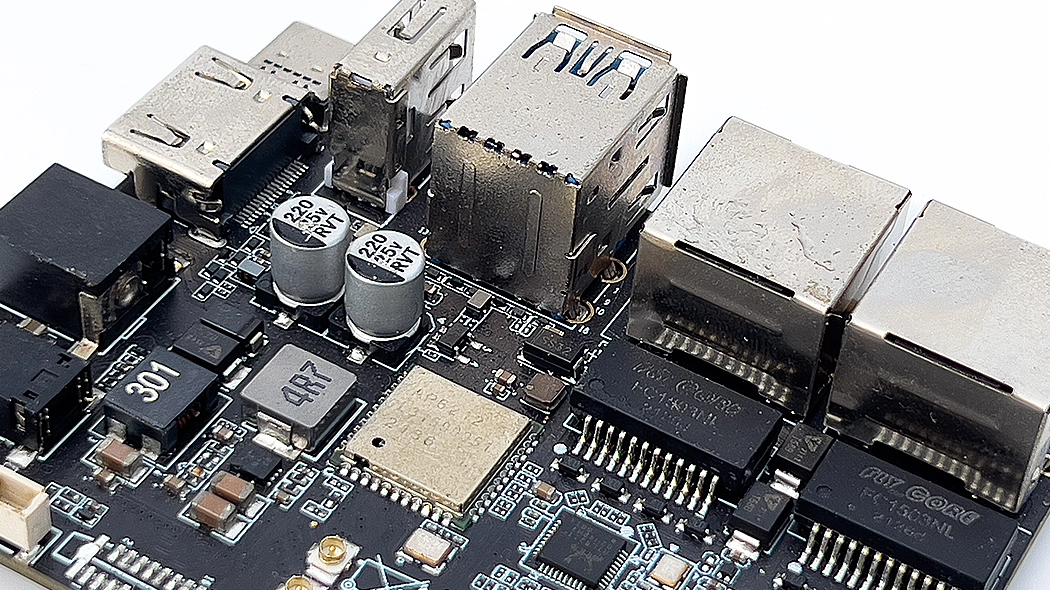

For example, mismatched pin counts or spacing, or unreasonable pad design, can lead to problems such as cold solder joints, short circuits, and tombstoning during SMT assembly or reflow soldering, significantly increasing the rework rate and affecting product consistency and reliability.

(5) Ambiguous Model Numbers

Different brands and batches of the same type of component may vary in accuracy, temperature drift, lifespan, and consistency. If the BOM does not clearly specify the brand or acceptable alternatives, the final product performance may fluctuate, affecting product quality and brand reputation.

Approximately 21% of PCBA surface mount defects are caused by BOM errors or missing information.

3. What high-quality conditions must a BOM meet in PCB manufacturing assembly?

(1) Complete Information

The BOM should list in detail all components and materials used in the circuit board manufacturing process, including the name, model, quantity, brand, part number, etc., for each component.

(2) Accuracy

The information in the BOM should be accurate to ensure that the correct components are used in the PCB board production process, thereby guaranteeing the functionality and quality of the finished circuit board.

(3) Real-time Performance

Using a real-time BOM can avoid errors caused by information lag, which could affect the circuit board delivery schedule.

(4) Practicality

The BOM can guide all aspects of procurement, production, quality control, cost control, and maintenance, ensuring transparency and efficiency in printed circuit board production.

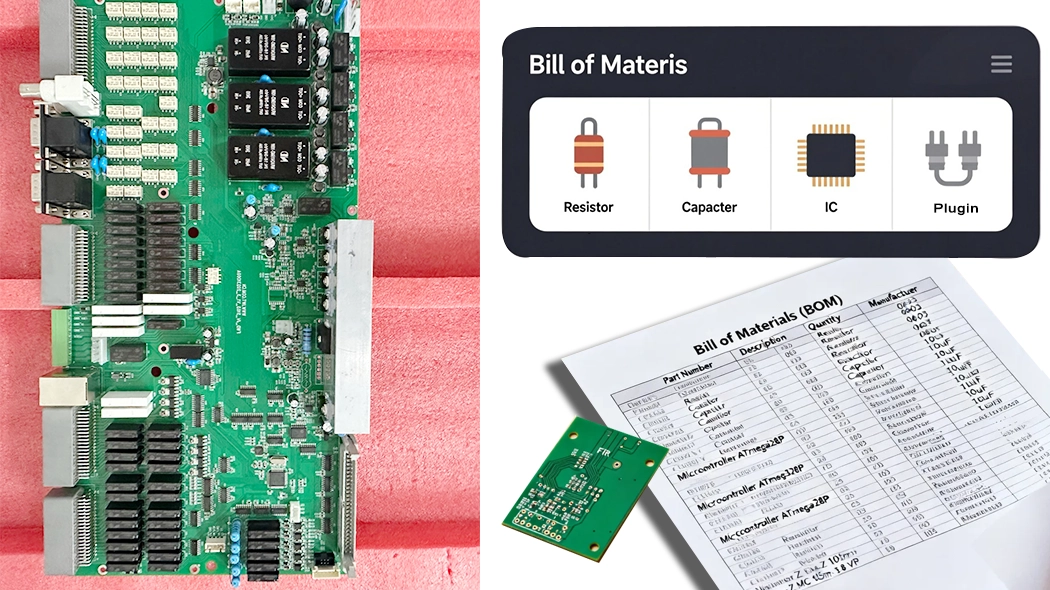

Provide PCBA manufacturers with a Bill of Materials (BOM) so they can printed circuit board production

4. SCSPCBA Smart BOM Quote Platform

Compared to other PCBA quotation websites that only summarize material prices, SCSPCBA’s BOM Quote system helps customers mitigate production risks.

(1) Real-time supply chain data comparison

The SCSPCBA BOM engine performs the following:

- Inventory check

- RoHS / REACH compliance check

- Delivery date prediction model (based on historical trends)

- Component price fluctuation monitoring

SCSPCBA BOM quote can help customers reduce component cost fluctuation risk by 8–12%.

(2) Identifying Ambiguous Part Numbers to Improve Matching Rate

Ordinary BOM tools can only match “surface model matching.”

SCSCPCBA’s BOM platform can identify the following by uploading files:

- Same specifications but different suffixes

- Automatic parameter completion when model specifications are incomplete

- OEM/ODM legacy part number mapping

(3) Recommended Alternatives

Component Alternatives:

- Compatible parameters, direct replacement

- Higher performance, similar or lower price

- Lower cost but fully compatible

- Suppliers and inventory

SCSPCBA’s component alternative recommendations can help customers save an average of 5–18% on BOM costs.

(4) Faster Cost Assessment

Unlike other website quoting tools that typically only display material prices, SCSPCBA’s intelligent BOM quotation service can provide the following within seconds:

- Component unit price

- Whether a replacement is needed

- Process complexity

- Quickly estimate product prototyping material costs

- Intelligent BOM comparison analysis to avoid quantity errors

- Connect with suppliers to provide quotations for readily available component inventory

5. Best Practices Guide: Before uploading BOMs to the SCSPCBA Instant Quotation System

For ODM/OEM companies, the BOM (Bill of Materials) is not just a procurement list, but a core document connecting circuit design, pcb board fabrication, and cost control. Thorough preparation before uploading the document to the SCSPCBA BOM instant quotation system can significantly improve quotation accuracy, shorten communication cycles, and reduce subsequent production risks.

(1) Include “Design Intent” in the BOM to Reduce Hidden Communication Costs

In real-world projects, many problems do not stem from technical difficulties, but rather from a lack of information. It is recommended to proactively supplement key specifications in the BOM (Bill of Materials) to help the system and engineering teams quickly understand your actual needs. For example:

- Whether components require mounting, and the mounting surface.

- Whether equivalent replacements are acceptable, and the priority of replacements.

- Description of tolerance ranges for key parameters (e.g., resistance, ESR, accuracy class).

- Special attribute markings, such as anti-static, moisture sensitivity rating, automotive-grade, or medical-grade requirements.

These details can effectively avoid “default assumptions” and are especially important in high-reliability PCB/PCBA projects such as automotive electronics, medical electronics, and industrial control.

(2) Use structured file formats to improve system recognition efficiency

To maximize the efficiency of SCSPCBA’s intelligent quotation system, it is recommended to prioritize the use of editable and clearly structured file formats such as XLSX, XLS, and CSV.

- Avoid using BOMs in the form of images or screenshots.

- Maintain consistent field order and clear naming.

- Use a consistent template structure within the same project as much as possible.

Structured data not only facilitates rapid system parsing but also reduces the time spent on manual secondary confirmation.

(3) Complete BOM Information

Before uploading, you can check the following elements to ensure that the information is complete and traceable:

- Clear line numbers for easy communication and location

- Quantity per PCB

- Reference Designator

- Explicit Manufacturer Part Number (MPN)

- Manufacturer Brand Name

- Component Function and Package Description

- Remarks: Alternatives, Limitations, or Special Notes

The more complete the BOM, the closer the quoted price will be to the actual production cost.

(4) A Shift in Mindset from “Quotation Document” to “Manufacturable Document”

Many ODMs/OEMs only use BOMs as a tool for requesting quotes, but in SCSPCBA’s actual projects, we prefer it to be an engineering document directly applicable to production decisions.

In our system, the BOM is not only used for price calculations but also linked to:

- Component availability assessment

- Risk material warnings

- Cost optimization and substitution suggestions

- Subsequent SMT and PCBA process matching

Spending an extra 10 minutes perfecting the information before uploading the BOM can often save hours or even days of repeated communication.

SCSPCBA has successfully handled hundreds of BOM structures and complex variations; our intelligent quotation system is designed specifically for this type of “engineering-grade BOM.”

For ODMs/OEMs seeking efficiency, reliability, and cost transparency, this step deserves serious attention.

6. FAQ

(1) What is a high-quality BOM?

It includes the complete model number, package, brand, specifications, quantity, description, and optional alternatives, and provides good support for manufacturability.

(2) What is the difference between a BOM quote and a PCBA quote?

A BOM quote focuses on component cost, inventory, and risk; a PCBA quote includes PCB, SMT processes, and testing.

(3) What are the advantages of SCSPCBA’s BOM quotes compared to other websites?

Real-time supply chain data, lifecycle management, process analysis, alternative material recommendations, multi-source price comparison, and end-to-end integration.

(4) I only have a BOM, not Gerber; can I still get a quote?

Yes, scspcba supports XLSX, XLS, and CSV file formats, with a file size not exceeding 2MB.