Aluminum Printed Circuit Board Manufacturing Solutions

What is Aluminum PCB

Aluminum PCB is a metal-based printed circuit board with aluminum alloy as the substrate. It is usually composed of three layers:

- Circuit layer (copper foil)

- Insulation layer (thermal conductive medium)

- Metal base layer (usually aluminum)

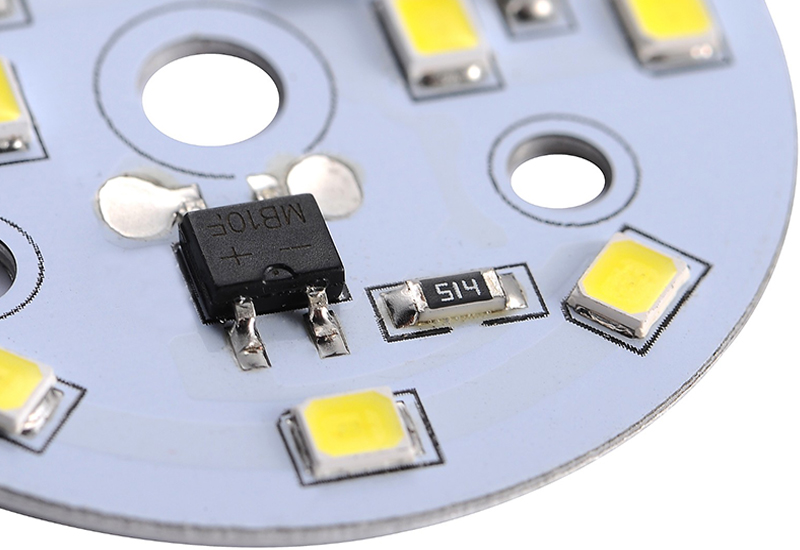

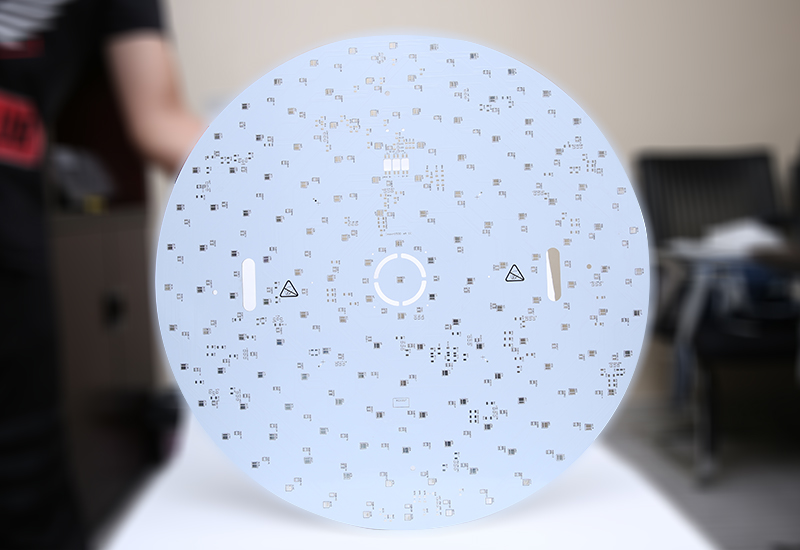

The biggest feature of aluminum PCB is that its metal base gives it excellent thermal conductivity and mechanical strength. It can effectively transfer the heat generated by electronic components to the aluminum layer and dissipate it, effectively improving product stability and service life. Aluminum circuit board are widely used in fields that require efficient heat dissipation, such as LED lighting, power modules, and automotive electronics, and are ideal for high-power electronic devices.

Common Applications of Aluminum PCB

Aluminum PCB boards play an irreplaceable role in multiple industries due to their excellent heat dissipation and structural stability:

- LED lighting – enhanced heat dissipation, longer life, more stable operation – suitable for LED light strips, high-power bulbs, street light modules

- Power modules – efficient thermal control, improved system reliability – suitable for driver power supplies, adapters, inverters

- Automotive electronics – high temperature resistance, durable in harsh environments – suitable for headlight controllers, battery management systems (BMS)

- Communication equipment – light and strong, best thermal management – suitable for amplifiers, antenna power modules

- Industrial equipment – high efficiency under thermal stress – suitable for motor drives, industrial sensors, power device baseplates

How Do Aluminum PCBs Outperform Traditional PCB Materials?

Compared with traditional FR-4 and other resin material PCBs, aluminum PCBs have the following key advantages:

- High thermal conductivity: Aluminum circuit board has superior thermal conductivity. The heat generated by electronic components is quickly transferred to the aluminum substrate, effectively reducing local temperature rise and preventing overheating and damage to the device, thereby extending the life of the entire device.

- High mechanical strength: Aluminum circuit on board are resistant to impact and deformation, and are not easy to deform, making them suitable for installation in vibration or harsh environments.

- High volume compressibility: Aluminum PCBs support more compact structural designs, and have higher integration and cost-effectiveness in high-power, small-volume devices.

The Core Advantage of Aluminum PCBs

| Advantages | directions |

|---|---|

| 1. Excellent heat dissipation performance | Conduct the heat generated by electronic components to the aluminum layer and diffuse it into the air, reducing thermal resistance, preventing device overheating |

| 2. High cost performance | Compared with high-end heat dissipation materials such as ceramics, aluminum PCB costs are more controllable and can meet most medium and high power heat dissipation requirements |

| 3. Environmental protection | Aluminum is recyclable, which is in line with the concept of green environmental protection; at the same time, it has low density and light weight, which facilitates the lightweight design of the whole machine |

| 4. Mechanical strength | The aluminum PCB itself has good tensile strength and rigidity, making the circuit board more impact-resistant and less prone to deformation |

| 5. Easy to process | CNC, drilling, and stamping are highly efficient and easy to mass-produce printed circuit board |

Aluminum PCB Design Considerations

When designing aluminum PCB, optimize the design from multiple dimensions to achieve the heat dissipation effect of aluminum

- Thermal management: Ensure that the heat flow path between the electronics components and the aluminum base is the shortest;

- Component layout: The arrangement of components will affect the heat distribution of printed circuit manufacturing. High-heat components should be placed close to the aluminum core to shorten the heat path, optimize the heat distribution, and prevent local overheating. At the same time, heat-sensitive components should be avoided near heat sources.

- Layer stacking: For double-sided PCB or multi-layer aluminum PCBs, reasonable arrangement of signal layers, power layers, and ground layers can not only enhance signal integrity, but also help build heat dissipation paths.

- Design for manufacturing (DFM) principles: Simplifying PCB layout and selecting appropriate printed circuit board materials and a PCB fabrication process can help reduce manufacturing costs, error rates, and delivery cycles.

Aluminum PCBs’ thermal performance and production efficiency can be greatly improved by optimizing thermal via locations, component layouts, stacking structures, and DFM execution.

The Manufacturing Process of Aluminum PCBs

The aluminum circuit board manufacturing process requires precision and attention to detail at every stage, from material selection to final testing.

1. Preparation of aluminum-based copper-clad laminate

At the beginning, select aluminum-based copper-clad laminate (usually including aluminum base layer, insulation layer and copper foil) with appropriate thickness and thermal conductivity, and perform surface cleaning and degreasing treatment to ensure smooth subsequent processes.

2. PCB Material Selection

Select according to product requirements:

- Copper foil thickness (usually 1oz-3oz)

- Aluminum substrate thickness (0.8mm, 1.0mm, 1.6mm, etc.)

- Thermal conductive insulation layer type (thermal conductivity 1~9W/m·K)

3. Graphic transfer & etching

The circuit pattern is transferred on the copper surface through dry film or wet film, and then the excess copper foil is removed by acid etching process to retain the required circuit.

After etching, cleaning and inspection are carried out to ensure that the circuit is complete and there is no residual copper.

4. Drilling & deburring

According to the design requirements, through holes or countersunk holes are drilled at the specified location for subsequent pin insertion or assembly.

After drilling, deburring, cleaning and hole wall treatment are carried out to ensure the electrical and structural integrity of the through hole.

5. Solder Mask

Print green, white or black solder mask ink (solder mask) on the surface of the circuit board, leaving only the pad exposed to prevent solder short circuit or oxidation.

Use exposure, development and curing processes to ensure the accuracy and adhesion of the solder mask.

6. Surface treatment

Surface treatment of the pad part to enhance solderability and anti-oxidation performance. Common treatment methods include:

- OSP (organic solderability protection)

- ENIG (immersion gold)

- Lead-free tin spraying

- Silver plating

The choice depends on the soldering method, storage life and product use.

7. Forming, testing and inspection

Use CNC or molds to form and cut the circuit board to ensure dimensional accuracy and hole alignment.

Then proceed with:

- Appearance inspection

- Electrical test (open circuit/short circuit detection)

- Functional test (if it is a whole board with components)

Ensure that the aluminum PCB meets performance standards and customer specifications before leaving the factory.

Challenges Faced by Aluminum PCB Production

Although PCB has obvious advantages, the manufacturing process still faces the following challenges:

- It is difficult to control thermal stress: warping or delamination is prone to occur;

- High requirements for insulating medium materials: thermal conductivity, insulation, and adhesion must be taken into account;

- High requirements for metal processing accuracy: the hole position and cutting edge of aluminum materials need to be precisely controlled;

- Narrow welding temperature window: high-power welding is prone to damage the copper layer or substrate

Why Choose SCSPCBA as Your Aluminum PCB Manufacturer in China?

Professional strength supported by scale and experience

Our headquarters and one-stop PCBA factory are in Shenzhen. We offer full PCBA services, including design, manufacturing, assembly, testing, and delivery, focusing on quality and timely delivery for global clients.

We also have a factory in Vietnam to serve our overseas customers better. This facility offers the same one-stop PCBA services, including design, manufacturing, assembly, testing, and delivery, ensuring high-quality and efficient solutions for international clients.

The Wuhan and US Branches provide fast, localized services, optimize production and logistics management, reduce costs and improve efficiency, and offer customers competitive prices.

SCSPCBA Advanced Aluminum PCB Manufacturing Capabilities

● Aluminum Substrate Copper Laminate Clad GM-AL Series

| TYPE | features |

|---|---|

| AL-M-01 | Tg 130 -170C Aluminum substrate and copper foil, FR4 fiber glass Tg130-170 ℃ |

| AL-H-02 | Aluminum substrate and copper foil , no-fiberglass,thermal conductivity(Laird)3.0w/m..k |

| AL-H-03 | Aluminum substrate and copper foil,no-fiberglass, thermal conductivity(NRK)2.0w/m..k |

| AL-H- 04 | Aluminum substrate and copper foil,no-fiberglass, enduring 10 min at 35℃, dielectric constant 4.2 |

| AL-H-05 | Aluminum, copperfoil,no-fiberglass (Bergquist) thermal conductivity 2.0w/m..k |

● Special Series Copper Ciad Laminate GM-CU

CU-M-01: Thick copper clad laminate (40z~100z),super-current, Super-power circuit.

Meet the diverse quality requirements of multiple industries

SCSPCBA provides stable services from structural design optimization to batch shipment for customers in industries such as LED lighting, power electronics, automotive BMS, and communication equipment. Each aluminum substrate is accompanied by a complete traceability number to ensure consistent quality and on-time delivery.

📩 Contact scspcba now to get a free online proofing quote and experience professional aluminum PCB manufacturing services