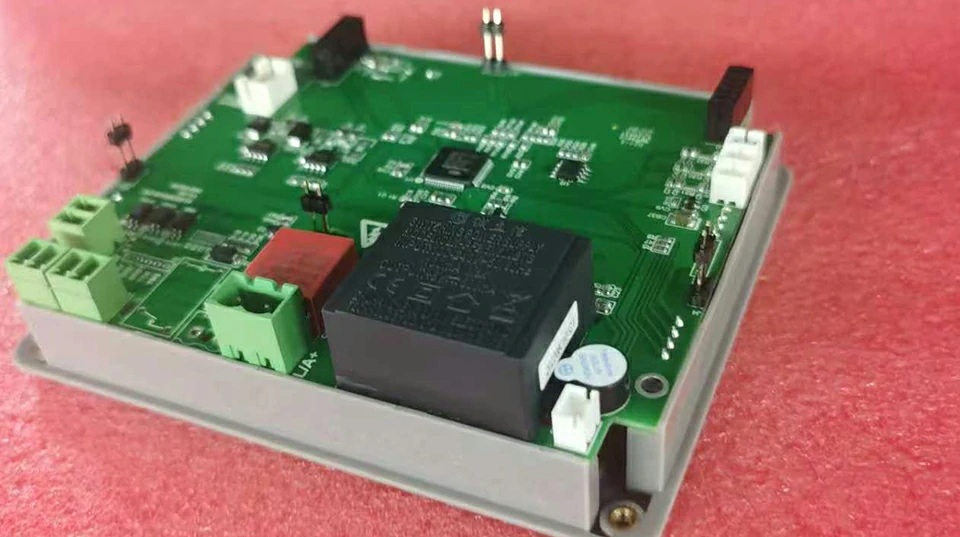

Our Box build assembly services are designed to deliver reliable, cost-effective, and scalable manufacturing solutions for OEM and ODM customers across multiple industries.

(1) Cost Efficiency & Quality Assurance

By integrating PCBA, cable assembly, mechanical assembly, testing, and packaging under one manufacturing system, box build assembly significantly reduces supply chain complexity and overall production costs. Standardized workflows, DFM reviews, and in-process inspections help ensure consistent quality and high yield rates, minimizing rework and field failures.

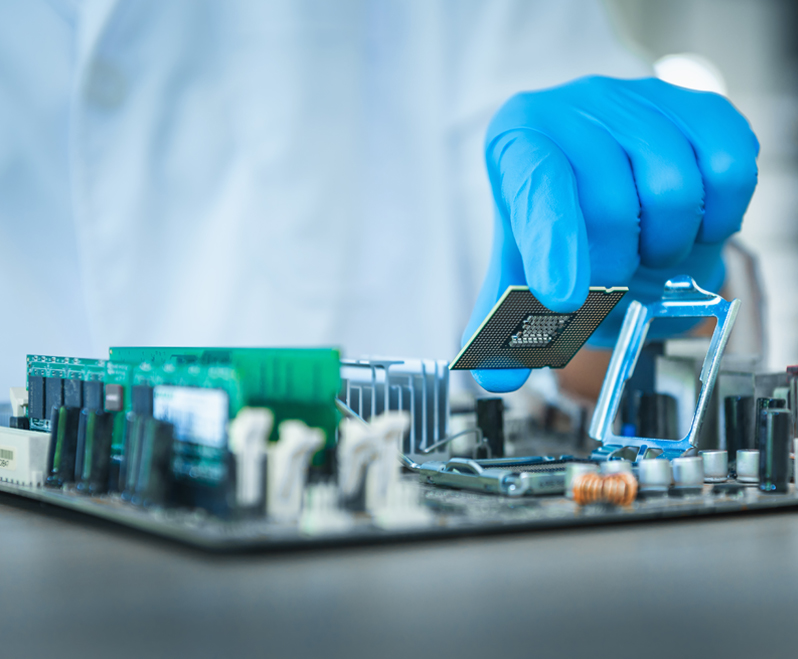

(2) Flexibility & Scalable Manufacturing

Box build assembly supports flexible production volumes, from prototypes and low-volume builds to high-mix, mass production. This scalability allows customers to adapt quickly to market changes, shorten time-to-market, and seamlessly transition from pilot runs to full production.

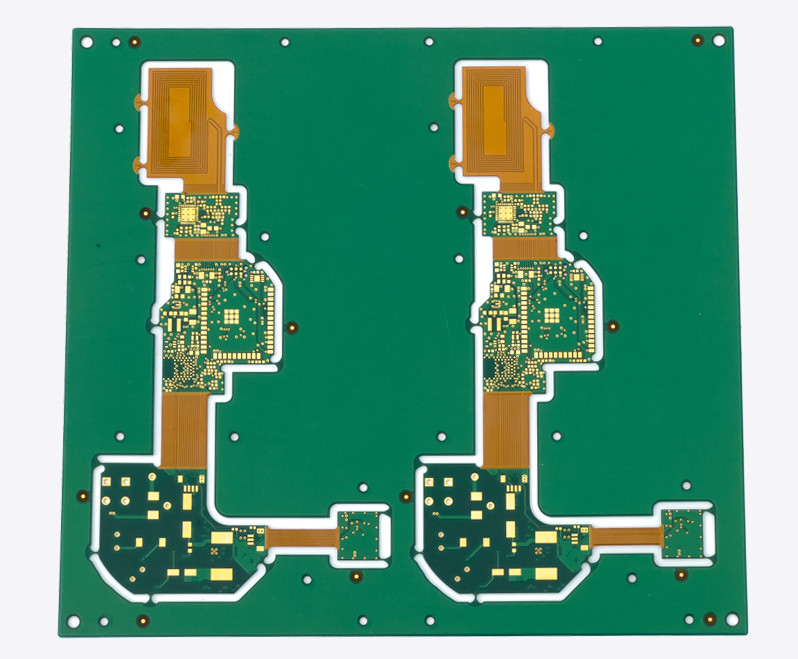

(3) Advanced Automation & Process Control

Advanced automation technologies, such as automated SMT lines, precision wire harness assembly, and functional testing systems, improve assembly accuracy and repeatability. Automated processes also enhance efficiency, traceability, and long-term product reliability.

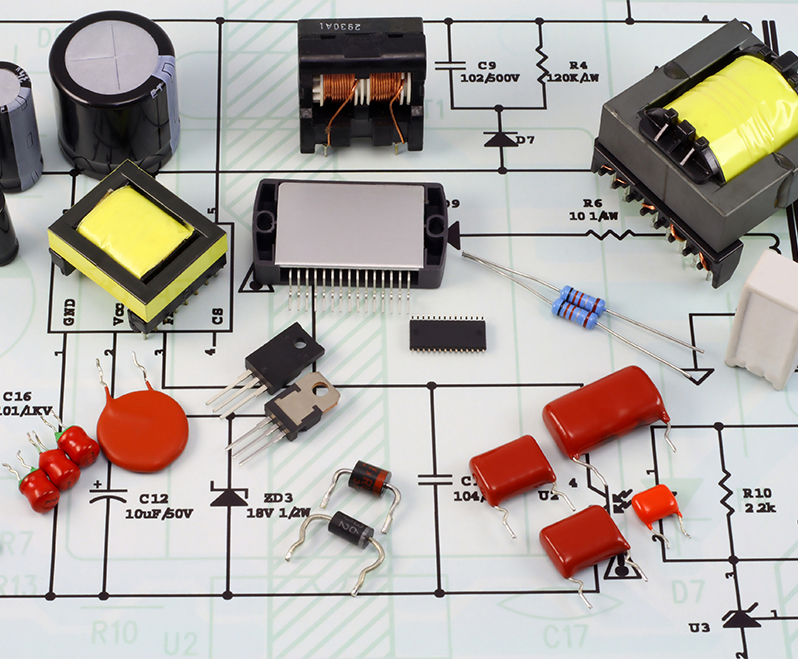

(4) Ideal for Both Customization & Mass Production

Whether for customized electronic systems or standardized products, box build assembly combines engineering support with manufacturing efficiency. This balance makes it ideal for industries requiring both tailored solutions and stable, large-scale output.