Box Build Ouote Service for OEM & ODM

1. Understanding PCB, PCBA, and Box Build Assembly

PCB: a bare board containing unassembled electronic components.

PCBBA Manufacturing: This process primarily involves component mounting (SMT or THT), soldering (reflow soldering or wave soldering), and testing (AOI, X-ray, ICT, etc.). It is an intermediate stage in the manufacturing process, focusing on the production and functional implementation of the circuit board.

Box build assembly: Assembling the PCBA-processed circuit board with other components (such as housings, connectors, heat sinks, etc.) to form a complete electronic product.

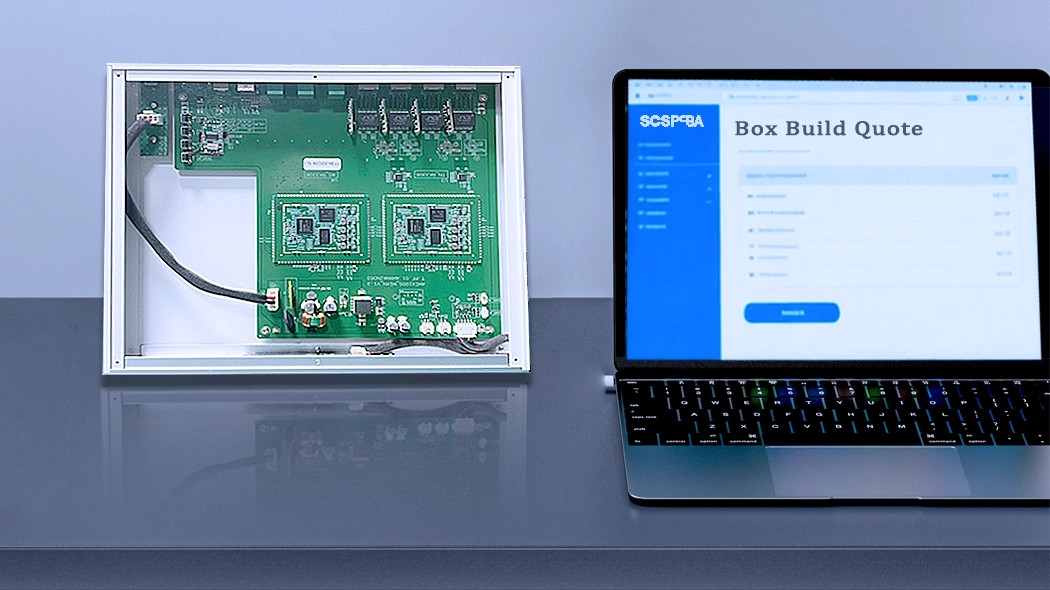

2. Box Build Quote Service

When your project goes beyond just PCBs or PCBAs, requiring the integration of circuit boards, components, wiring harnesses, enclosures, structural parts, functional testing, final assembly, and even complete system shipment into a single system, box build quote is designed for these complex needs.

Contents of Box Build Quote

On the intelligent quotation platform, you can upload complete project materials (e.g., a ZIP archive containing Gerber, BOM, structural diagrams, wiring harness list, enclosure drawings, etc.). After submission, a professional engineer will provide you with a quotation.

The Box Build Quote quotation will include the following:

- BOM Quotation List

- PCB board fabrication: number of layers, multilayer PCB, HDI, impedance board, PCB materials, surface treatment

- PCBA surface mount: SMT, DIP, THT assembly, wave soldering, etc

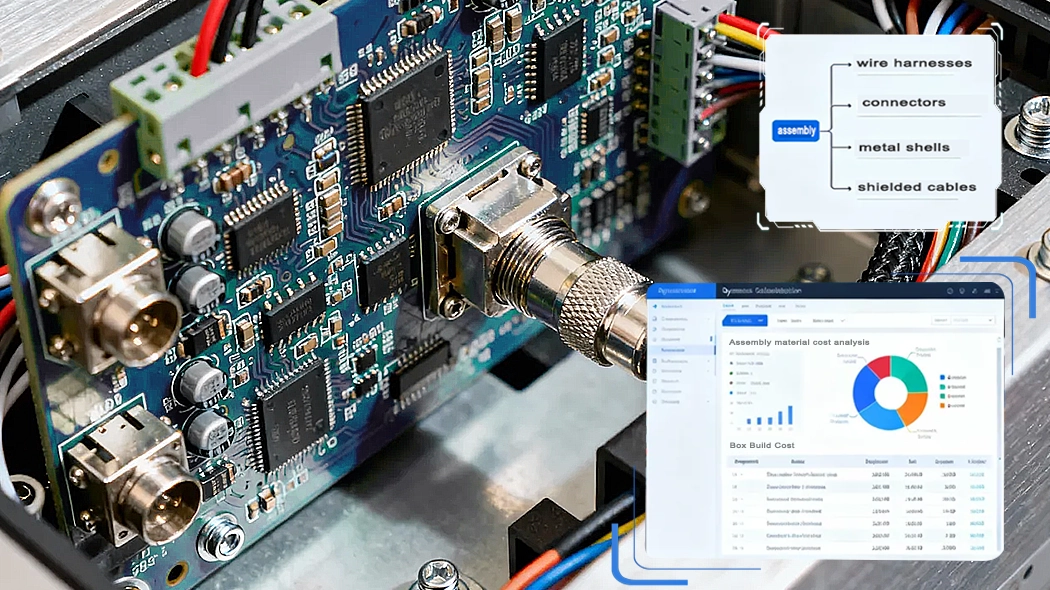

- Materials and labor assembly: wire harnesses, cables, connectors, power cords, shielded cables, ribbon cables, wire harness assemblies, etc.

- Enclosure installation: plastic shells, metal shells, brackets, heatsinks, chassis

- System-Level testing: Post-assembly FCT/ICT/aging tests/complete functional tests, environmental tests to ensure overall product quality upon shipment.

- Transparent pricing throughout the process: the quotation includes material costs, assembly costs, testing fees, structural component, and assembly labor costs.

3. Advantages of Choosing SCSPCBA Box Build Quote

Compared to traditional suppliers who only quote for PCBs or PCBAs, SCSPCBA offers a turnkey service encompassing PCB + SMT + testing + final assembly. This integrates the entire process from raw material procurement to final product assembly, reducing intermediaries, providing greater transparency, stronger supply chain integration capabilities, and a more comprehensive integrated manufacturing solution, resulting in better cost control.

(1) Turnkey Service

- Cost Control

From raw material procurement → PCB → PCBA → wire harness materials → complete assembly → testing → packaging and shipping, SCSPCBA handles everything in one integrated process, avoiding rework caused by communication errors between suppliers. - Rapid Quotation

Based on an AI + data-driven quotation system, including BOM service, PCB quotation, PCBA quotation, and finished product assembly, a complete quotation can be obtained in a short time after uploading project information, eliminating the need for multiple rounds of manual confirmation and greatly shortening the initial cycle. - Data Traceability and Clear Responsibility

Every component, wire, structural part, processing technology, and testing procedure is meticulously recorded. In case of quality issues, responsibility is clearly defined, eliminating the complexities of investigation and evidence collection. The one-stop service manufacturer handles all problems. - Customization Services

One-stop PCBA services offer a streamlined approach to product customization. All production processes can be more collaborative, which is especially important for ODM projects. - Adaptable to High Reliability Requirements

Supports complex PCBs, mixed SMT/DIP/BGA, wire harnesses and structural components, high-density assembly, and testing-inspection. Suitable for high-standard industries such as automotive electronics, medical devices, industrial control, and communication equipment. - From Prototype to Mass Production

Whether you need a few prototypes or thousands of units for mass production, Box Build services can adapt, eliminating the need for scattered suppliers or coordination concerns.

(2) SCSPCBA’s Box Build Assembly Quotation Service Relies on

- Rich experience

Over 12 years of PCBA manufacturing experience - Multiple production bases

Four advanced manufacturing bases are located in Shenzhen, Jiangsu (China), Jiangxi (China), and Vietnam, covering the entire process from PCB manufacturing to PCBA assembly and complete system integration. Each factory is equipped with automated SMT production lines, DIP production systems, and digital traceability systems, ensuring high-quality, efficient, and flexible manufacturing services for global OEM and ODM customers. - Multiple fields

Historical production data covering automotive, industrial, and consumer electronics sectors - Professional Team

A professional team of purchasing, circuit board manufacturing process, and testing engineers

(3) Every Quote is Backed by a real PCB Assembly factory

SCSPCBA box build quotes are not from an intermediary platform, nor are they generated in isolation; they are verified through actual production capabilities.

All prices are based on the following factors:

- Automated Optical Inspection (AOI), X-ray inspection, vibration testing, thermal cycling testing, and salt spray testing.

- Each factory is equipped with automated SMT production lines and DIP production systems.

- In-Circuit Testing (ICT) and functional testing.

- Certified to ISO 9001, IAFT, RoHS, UL, and IPC-A-610 standards, ensuring production capacity for automotive, medical, and consumer electronics products.

- Continuous engineering audits for complex projects.

This ensures that quotes reflect actual production conditions, rather than being based on assumptions.

(4) Intelligent BOM Analysis

This is crucial for final assembly pricing. Unlike general-purpose platforms, BOM services include:

- Real-time component availability signals

- Recommended alternative components (same package size and electrical rating)

- Lifecycle status (available/discontinued/already discontinued)

- Cost analysis by quantity level

This is especially important for ODM projects, as BOM decisions impact long-term manufacturability.

4. Box Build Quote ≠ Complete System Assembly Only

Complete PCB assembly pricing is based on end-to-end system integration (PCBA + Housing + Wiring + Sub-components), and also needs to consider various factors, such as:

- Copper Foil Thickness

Different thicknesses of copper foil have significantly different prices; for example, copper foil ranging from 0.5oz to 3oz will have different prices. - Solder Mask Type

Solder mask inks are categorized into photosensitive inks, thermosetting inks, and photocurable inks, with each type having a distinct price. - Surface Treatment Processes

PCB copper foil surface treatment processes include flux treatment, OSP anti-oxidation treatment, silver plating, leaded tin plating, lead-free tin plating, electroplating with water gold, electroplating with pure gold, etc. The higher the process level, the higher the price. - Application Scenarios

PCBA boards are used in various types of electronic devices, from simple to complex. The complexity of the application scenario will affect the price. - Signal type

The choice of PCB layer count depends on the type of signal to be transmitted, such as high-frequency, low-frequency, ground, or power signals. These may require different grounding and isolation methods. - Hole type

The choice of via type (e.g., buried vias) will affect the layer count requirement, thus affecting cost. - Pin density

Higher pin density requires more layers and increases cost. - Manufacturing cost

Multilayer PCBs are more expensive than single-layer PCBs; manufacturing cost is one of the determining factors in choosing the number of layers.

A complete PCB manufacturing and assembly quote needs to be considered comprehensively to ensure that the quote accurately reflects the actual project situation. If you need a specific quote, it is recommended to contact a professional printed circuit board assembly manufacturer and provide detailed design requirements and specifications to obtain an accurate quote.

5. Box Build Quote Application Industries

PCBA box build quote has a wide range of applications, covering multiple industries and application scenarios:

(1) Industrial PCB Manufacturing Assembly

Industrial testing equipment such as smart instruments and sensors rely on PCBAs to achieve data acquisition and transmission.

(2) Medical Device Electronics Assembly

PCBAs are used in medical imaging equipment, blood meters, electrocardiographs, and other equipment to achieve real-time monitoring of patients’ vital signs and treatment control.

(3) Automotive PCB Assembly

PCB fabrication assemblies are used in vehicle electronic control units, sensors, battery management systems, lighting, vehicle navigation systems, airbag systems, etc., and must withstand harsh environments such as vibration and high temperatures during vehicle operation.

(4) Consumer Electronics

PCBA electronic assemblies in audio-visual equipment such as televisions and stereos are responsible for signal processing, audio amplification, and other functions

(5) Computer Field

The computer motherboard is one of the largest PCBAs, housing key components such as the central processing unit, memory, and chipset.

(6) Communication Equipment

Mobile phones contain multiple PCBAs, such as the motherboard and RF board, integrating components such as processors, RF chips, and antennas to enable functions such as making calls, accessing the internet, and taking photos.

6. Box Build Assembly Quote for OEM / ODM / EMS

The traditional “PCB/PCBA first, then outsource structure + wiring harness + testing + assembly” process often suffers from delayed mold opening, high rework rates, difficulty in traceability, and opaque costs due to multiple supply chains, multiple rounds of communication, version conflicts, and delivery delays. Box Build assembly integrates the entire process into a single contract, a single supply chain, and a single pricing system, significantly reducing risk and improving efficiency and controllability. It represents best practice for EMS/OEM/ODM projects.

Through SCSPCBA’s Box Build Quote, you no longer need to separately find PCB manufacturers, surface mount manufacturers, structural component manufacturers, assembly plants, and testing plants—we integrate everything, providing detailed cost breakdowns and ensuring a complete, transparent, controllable, and high-quality one-stop service from design to finished product delivery, helping clients make informed decisions.

(1) Comprehensive Cost Accounting

The complete assembly quote includes all necessary costs, such as material procurement, labor, testing, and packaging. This allows clients to clearly understand the total investment required for their project.

(2) Flexibility

OEM and ODM projects typically require customization, and complete system assembly quotes can be adjusted based on specific customer needs. Whether it’s simple assembly or complex system integration, the quote can be adjusted accordingly.

(3)Quality Assurance

SCSPCBA typically handles complete system assembly projects with stringent quality control measures. Quotes may include costs related to testing and ensuring the final product meets required standards.

Whether you are an OEM brand owner, ODM manufacturer, or EMS outsourced engineering team, the box build assembly quote will greatly simplify processes, shorten lead times, and reduce risks.

7. Want to Get A Complete Quote for Box Build Assembly Immediately?

Simply click the button below and upload your project information (German language + BOM + structural diagram + wiring harness list). We will provide a complete quote in a short time—including material costs, assembly fees, testing fees, structural component costs, delivery time, and logistics solutions.

Or contact us through the following methods:

Email: [email protected]

Phone: +86-755-2561-8511

8. Box Build Assembly Quote Service FAQ

1. What is included in a Box Build assembly quote?

A complete quote covers PCBA, enclosure, cables, sub-assemblies, testing, and final integration.

2. Can I get a quote without finalized drawings?

Yes. Early-stage quotes can be generated using preliminary BOMs and reference designs.

3.Can SCSPCBA suggest BOM alternates?

Yes. Engineers recommend footprint-compatible and lifecycle-safe alternatives.

4. Is this suitable for low-volume ODM projects?

Absolutely. The system supports prototypes and pilot builds.

5. Can the quote scale to mass production?

Yes. Cost curves and volume pricing are provided.

6. Is this service limited to certain industries?

No. It supports industrial, automotive, medical, and consumer electronics.