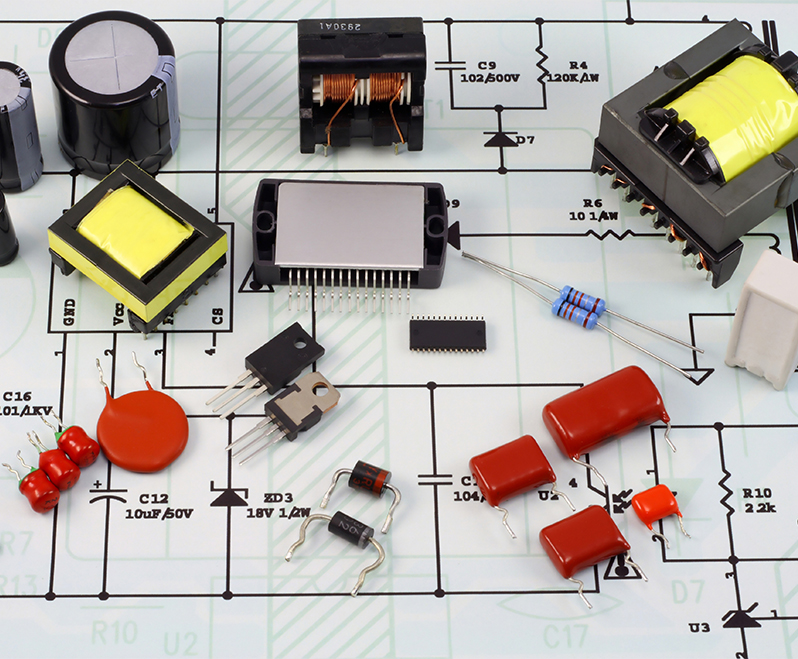

In such a market environment, PCB (Printed Circuit Board, printed circuit board) assembly and production have become a very important link. Since most consumer electronic products use similar electronic components and designs, the cost of the PCB assembly process is relatively stable. Therefore, fierce competition has been launched among enterprises to grab more orders and market share.

● High-end Consumer Electronics Pose Challenges to PCB Quality

Different from low-end consumer electronics products that pursue the ultimate cost performance, high-end consumer electronics products have strict requirements on PCB materials and fabrication.· Complexity and Density

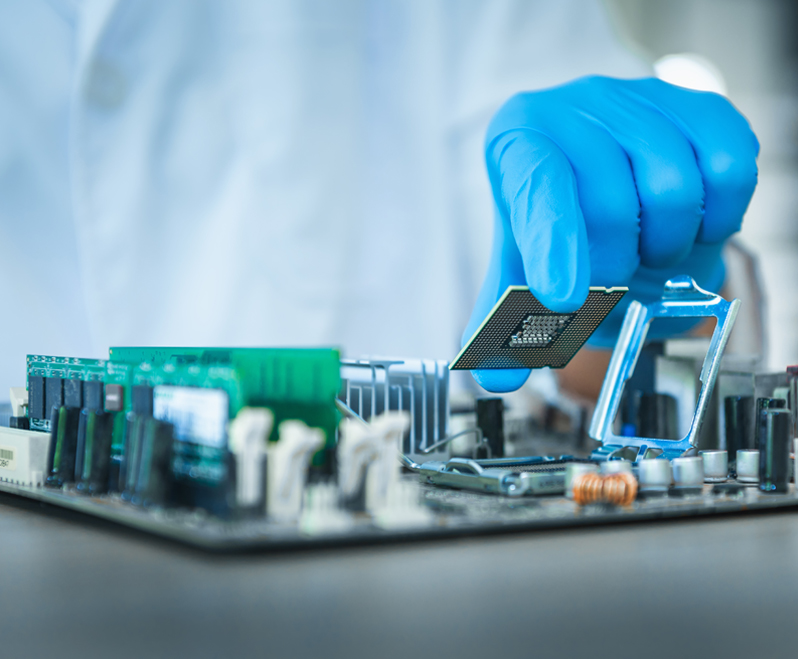

High-end consumer electronics typically require more complex and denser PCBA Manufacturing. This means that more components need to be placed on the PCB assembly, and the spacing between these components is smaller. Therefore, the production process requires a higher level of precision and skill to ensure that components are installed and connected correctly while avoiding short circuits or other manufacturing defects.

· High-performance Requirements

High-end consumer electronics products typically have higher performance requirements such as faster processing speeds, higher energy efficiency and more reliable functions. This requires that the PCBA design and manufacture must have higher quality standards to ensure stable and reliable product performance. For example, HDI boards have higher and higher requirements for inner layer wiring and graphic size control. There are many layers, and the thin core board is easy to wrinkle, which makes it more difficult to control the alignment accuracy between the inner layers, and also increases the production cost.

· Variety and Customization

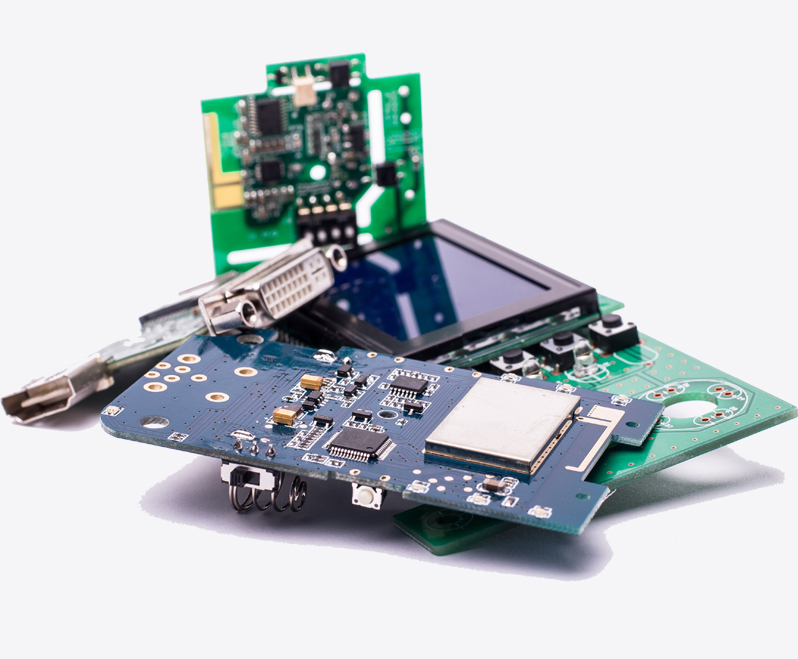

The demand for product diversity and customization in the high-end consumer electronics market continues to increase. Consumers have higher expectations for personalized products and functions, which means that PCBA manufacturers must have greater flexibility and be able to adapt to various product designs and requirements.

· Packaging Technology

Some high-end consumer electronics products adopt new packaging technologies, such as BGA (Ball Grid Array), which require a higher technical level and more advanced equipment in the PCBA manufacturing and soldering process.

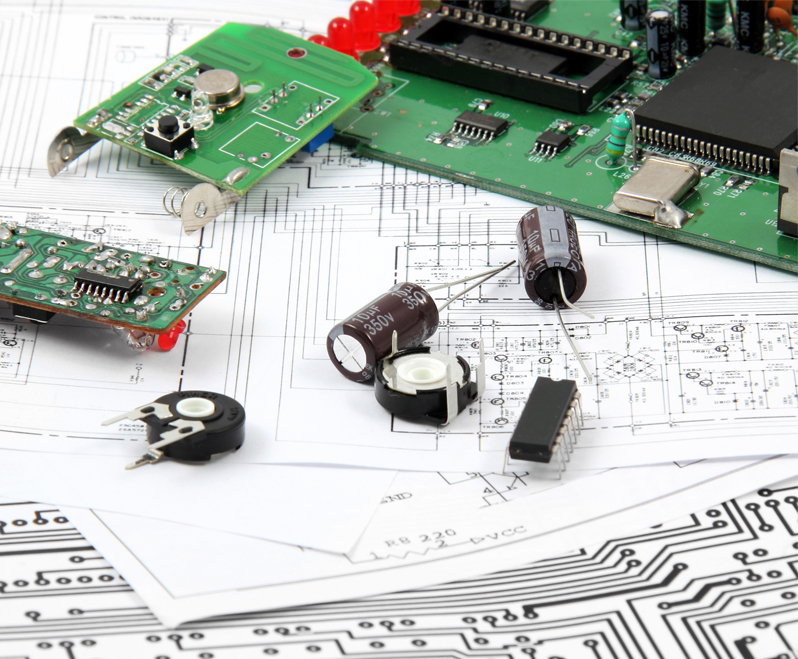

● PCB Assembly Inventory Pressure Caused by Fluctuating Consumer Electronics Demand

Due to the short life cycle of consumer electronics products, rapid demand updates, and the ever-changing consumption preferences of consumers, the rapid replacement of consumer electronics products has brought great challenges to PCBA manufacturers.

PCBA for consumer electronics often involves more suppliers and partners. In a globalized supply chain, ensuring the timely supply of components, quality control, and cost efficiency has become more complex and critical.

The consumer electronics market is highly competitive, and product updates and iterations are fast. To meet consumer needs, printed circuit board manufacturers must continue to conduct R&D and innovation and adopt new materials, processes, and technologies to improve the performance and reliability of PCBA.