Application of Data Analysis in PCB Board Production Quality Control and Production Optimization

In electronics manufacturing, printed circuit assembly is an extremely complex and quality-required process.

From circuit design, PCB fabrication, DFM checking, components procurement, PCB assembly, BGA assembly, firmware programming, box-build assembly to functional testing, each process may determine the quality of the entire circuit board. Process control is particularly important especially when meeting high-standard production needs such as the AS9100D aviation standard. Therefore, data analysis technology is gradually becoming an indispensable and important part of the printed circuit board assembly process, providing unprecedented precise insights and improvements to the PCB board manufacturing process.

1. Improve Production Quality

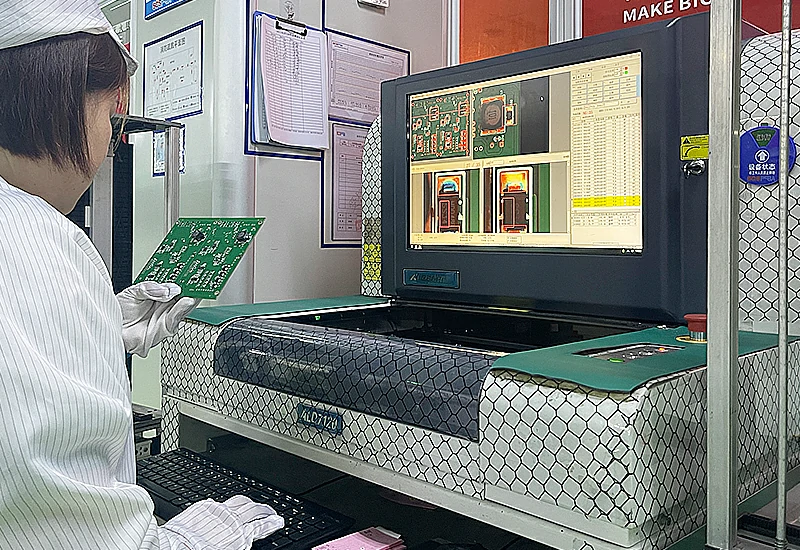

Quality control is always the core link in the PCB assembly production line. Even micron-level deviations may cause solder joints to be soldered, short-circuited, and even affect the reliability of the entire product, bringing potential risk of rework or recall. Through data analysis, PCB board manufacturers can handle problems from SPI (solder paste detection), AOI (automatic optical detection) and X-Ray detection in real time. Data analysis not only detects solder joint integrity and component alignment, but also intelligently judges abnormal patterns and predicts potential defects.

2. Optimize Production Process

Printed circuit board assembly process is complex, involving multiple links such as patch, reflow soldering, SMT patch, DIP plug-in, wave soldering, functional testing, etc. Any bottleneck may slow down the overall pace. With the help of data analysis, production managers can clearly grasp the key data such as the utilization rate of each equipment, material consumption, process conversion time and reasons for downtime, so as to accurately locate inefficient links. For example, when a patch machine frequently stops for a short time, the data system can promptly prompt whether it is necessary to adjust the material feeding rhythm or replace the aging component tray, eliminating the problem of inefficiency from the source.

3. Predictive Maintenance

The machinery and equipment stability directly determines the PCB assembly’s continuity and yield rate. With the help of big data analysis, circuit board manufacturers establish equipment health files and monitor the vibration, temperature, operating time and other indicators of core equipment such as placement machines, reflow ovens, and printers in real time. Once the data fluctuates abnormally, such as abnormal motor temperature rise and large bearing amplitude, the system will immediately issue an early warning to prompt preventive maintenance.

4. Optimize Supply Chain Management

During the PCB Board Assembly process, there are many types of components and complex technical specifications. Any shortage of key materials, delayed delivery or drastic price fluctuations will directly affect the execution of the entire production plan, and even lead to order delays and reduced customer satisfaction. By introducing an intelligent data analysis system, PCB fabrication manufacturer can monitor and manage the status of materials throughout the entire process in real time, including core data such as purchase orders, incoming batches, and inventory consumption rates.

The system can automatically generate the optimal procurement plan based on historical procurement cycles, market supply and demand changes, and supplier credit ratings to avoid inventory backlogs or shortage risks. For specific key components such as IC chips, MOS tubes, special connectors, etc. that have long delivery periods or are susceptible to global markets, the data system can also identify potential supply risks, issue warnings to the procurement department in a timely manner, and find alternative materials or secondary suppliers in advance.

In addition, the system can dynamically adjust procurement strategies and control procurement costs based on current market spot quotations. In the event of sudden changes in production demand or emergency orders, data analysis tools can recommend high-quality suppliers with spot resources to ensure a continuous supply of raw materials for the production line, fundamentally improving the flexibility and risk resistance of PCB assembly, and helping companies achieve the production goal of “zero material outages and zero waiting.”

5. Achieve Lean Manufacturing

In the PCB board manufacturing process, cost control is an important means for enterprises to continuously improve their market competitiveness. With the help of advanced data analysis technology, PCB board makers can achieve cost reduction and efficiency improvement in multiple links. First of all, data analysis can realize comprehensive monitoring of key quality indicators in the production process, and timely discover potential defects such as abnormal solder joints and patch offsets, thereby effectively reducing product defect rates and rework rates, and avoiding high after-sales or recall costs caused by failures after the finished product leaves the factory.

In addition, through data comparison and trend prediction, process engineers can find unreasonable energy consumption and consumables use in certain process links, and adjust parameters or replace equipment accessories in time to reduce the waste of raw materials. For core equipment such as patch machines, reflow soldering, and printing machines, data models based on predictive maintenance can accurately determine the best maintenance time, prevent the waste of manpower and material resources caused by excessive maintenance, and avoid sudden equipment failures that cause the entire line to stagnate and order delays.

In terms of raw material management, the data system helps enterprises scientifically set inventory safety lines based on actual production needs, component consumption speed and supply chain conditions, reduce backlogs and capital occupation risks, and reduce losses caused by expired materials. At the same time, the accumulation of historical production data and process control records has also become an important evidence for customer audits and qualification certifications (such as IATF16949, AS9100D, etc.), enhancing the trust and cooperation opportunities of enterprises in high-end manufacturing markets such as aviation, automobiles, and medical care.

In summary, data analysis technology not only improves the operating efficiency of PCB assembly production lines, but also helps PCBA companies achieve true lean manufacturing and cost minimization through full process detail optimization.

6. Helping to Achieve Low-cost and High-reliability Printed Circuit Board Production Goals

In the wave of intelligent manufacturing, data has become the core resource for PCB assembly factories to enhance their competitiveness. Data analysis covers every detail of PCB assembly, from production process monitoring and equipment health management to supply chain optimization and cost control. For companies pursuing excellent quality and efficient delivery, data-driven intelligent factories will be the only way for future development.