Full-process Solutions from Circuit Board Design to Finished Product Delivery

As the electronic manufacturing industry’s requirements for product complexity, delivery speed and customization capabilities continue to increase, one-stop circuit board assembly service providers with full-chain integration capabilities has become the common choice of more and more brands. SCSPCBA is committed to providing customers with integrated services from online quotation, circuit design, component procurement, printed circuit assembly, SMT patch and DIP plug-in, functional testing, to box build assembly, helping customers to efficiently implement product implementation.

1. Online Quotation System: Quickly Obtain Circuit Board Manufacturing Cost

SCSPCBA has created an intelligent online PCBA quotation system. Customers only need to upload the BOM table and Gerber file, and the system can automatically complete the analysis and estimation, and generate a complete quotation covering PCB board production, component procurement, SMT mounting, testing and printed circuit board assembly.

The intelligent online quotation system connects to multiple component supply chain platforms in real time, automatically compares prices, inquires about inventory, and recommends alternative materials, ensuring that the quotation data is transparent, accurate and feasible for procurement.

The intelligent online quotation system supports one-click ordering and online production progress tracking. Customers can view the arrival of materials, patch progress, test completion and logistics delivery status in real time.

2. PCB design: the first step from creativity to realization

As a one-stop printed circuit board manufacturers, we have an experienced team of PCB design engineers who can design schematics, PCB layout, and multilayer boards according to the customer’s original ideas, functional requirements or reference prototypes to ensure that the design meets the standards. At the same time, we also provide DFM (Design for Manufacturability) review to help customers avoid potential manufacturing risks and shorten the development cycle.

PCB Design Process of SCSPCBA:

● Step 1: Define your needs

Before the design begins, it is necessary to clarify the functional requirements, working environment, electrical performance indicators, size restrictions and cost budget of the product. This stage usually also involves collaboration with hardware, software, and structural engineers, and we can help you. Please contact us and we will develop a specific plan for you.

● Step 2: Schematic and PCB design

After discussing the requirements, we start the schematic design to ensure that all functional circuits are reasonable and logically correct, and then proceed to PCB design.

● Step 3: PCB Layout

Based on completing the schematic diagram, PCB board layer stacking planning, device layout, routing design, impedance control, power ground management, etc. are carried out to ensure signal integrity, EMC compatibility and reasonable thermal design. This link is particularly important for high-frequency and high-speed circuits.

● Step 4: Prototyping

Generate Gerber, BOM and other production files, and hand them over to PCB fabrication manufacturer to make samples. Samples can be used for SMT patches, functional welding and other processing processes.

● Step 5: Testing and startup

Use the test laboratory to perform power-on debugging, ICT testing, and functional verification on the samples to discover and solve potential circuit problems and ensure that the product meets the design standards.

● Step 6: Project maintenance

Our work does not end after the final product is put into production. We can maintain your design and are happy to help you review, modify or upgrade your design in the future.

3. Component Procurement: A Key Link to Ensure Delivery and Quality

We are equipped with an independent component procurement team, connected to mainstream supply chain platforms at home and abroad, and give priority to original spot channels to ensure the original quality of components, batch traceability, and fast delivery. In the context of global supply chain fluctuations, we can also provide alternative material solutions, taking into account cost and compatibility, to help customers reduce BOM risks.

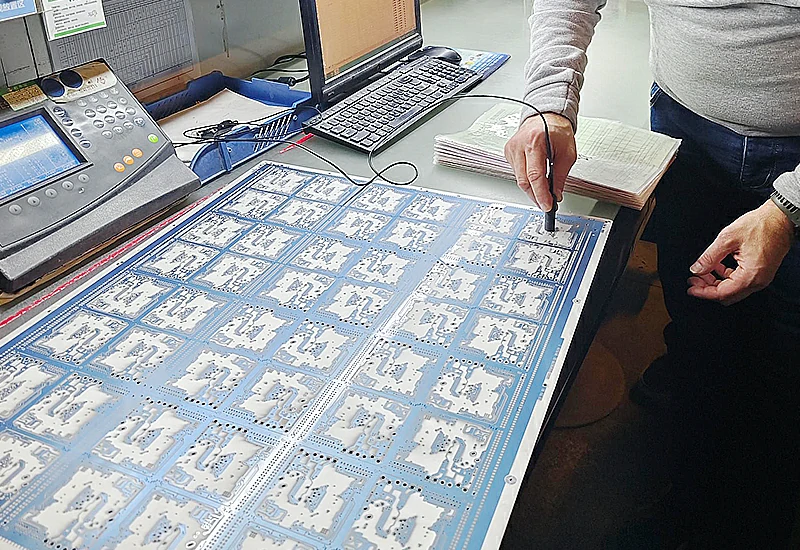

4. SMT Patch and DIP Plug-in: High-speed and Precise Core Manufacturing Power

● SMT Patch Processing

SMT patch processing is to directly solder surface mounted components (SMD) on the surface of PCB board, paste the components on circuit board through welding equipment, and then solder through hot air oven or reflow oven. This pcb manufacturing process eliminates the pins and holes of components, making the layout of PCB board more compact and suitable for the manufacture of high-density circuit boards.

Our SMT production line is equipped with fully automatic solder paste printer, 3D SPI inspection, patch machine, reflow oven and AOI optical inspection system to achieve mounting British 01005 (0.4mm*0.2mm), 0201 BGA.

SCSPCBA supports the manufacturing of electronic products with high-density layout, miniaturized design and automated production, such as consumer electronics, smart phones, laptops, etc.

● DIP Plug-in Processing

DIP plug-in processing is to connect the pins of plug-in components through the holes on the circuit board and then solder the pins to the other side of the PCB board. This pcb fabrication process requires wave soldering or manual soldering to complete the welding work. Compared with SMT patch processing, this process is relatively complex and is suitable for some special scenarios or occasions where the PCB board layout requirements are not high.

SCSPCBA supports prototype design in the R&D stage, small batch production or electronic products with large component sizes, as well as DIP plug-in processing of products with high mechanical strength requirements, such as industrial equipment, high-power resistors, and capacitors.

5. Circuit board Testing Service: Ensure Qualified Delivery

Quality is the premise of all our deliveries. We provide a variety of electronic assembly testing methods, including:

- ICT (in-circuit test),

- FCT (functional test),

- Aging test,

- X-Ray,

- Flying probe test

Ensure that each circuit board can run stably in the terminal system. We can assist in the development of test fixtures and programs according to customer needs, and support the integration of automated test processes.

6. Box Build Assembly: From Bare Board to Complete Device Assembly

Box Build Assembly services cover plastic/metal housing assembly, cable connection, labeling, packaging, aging testing, burning and other links, helping small and medium-sized enterprises simplify electronic product production.

Our Comprehensive Box Build Assembly Capabilities:

● PCB board fabrication and PCB assembly

We specialize in customized printed circuit board production, from circuit board design to final assembly, each component is carefully crafted to meet your precise specifications.

● Customized cable and printed circuit manufacturing

Our team is responsible for all cable harness and circuit board manufacturing aspects, seamlessly integrating electronic and mechanical components into your box construction.

7. OEM and ODM Services: Full Support from Drawings to Branded Products

For customers who have brands but lack R&D capabilities, we can provide OEM (original equipment manufacturer) foundry manufacturing services to ensure high-quality delivery of drawings and samples.

For customers who want to build their products from scratch, we can provide ODM (original design manufacturer) from the entire process of design to production, including hardware development, software collaboration, structural design, mass production introduction, and after-sales support, truly realizing “turnkey projects”.

With expertise in OEM and ODM printed circuit board production, we can provide high-quality circuit boards that fully meet customer specifications, ensuring the best performance and reliability of their electronic applications.

8. Choose SCSPCBA, Choose Professionalism and Efficiency

In the current increasingly complex environment of electronic manufacturing ecology, choosing a reliable, responsive, and one-stop PCBA partner with strong full-chain integration capabilities is the key for every company to reduce costs and increase efficiency, shorten the time to market, and achieve product success.

Whether you are a start-up project or a mass-produced brand, contact us to tailor a high-quality, efficient PCBA overall solution for you to help you stand out in the fierce market competition.