Vietnam PCBA Factory: One-Stop PCB Assembly Services for Global OEMs & ODMs

1. Why Vietnam Is a Strategic PCBA Manufacturing Base for OEM & ODM Projects

Vietnam has rapidly become a preferred destination for OEM and ODM electronics manufacturing, especially for companies seeking cost optimization, export flexibility, and supply chain diversification.

As a PCBA factory in Vietnam, SCSPCBA supports both:

- OEM PCBA manufacturing – build-to-print based on customer design

- ODM PCB assembly – design, engineering, and manufacturing support

Key advantages driving global OEMs and brand owners to Vietnam include:

- Competitive labor and assembly costs

- Favorable trade and export environment

- Growing electronics manufacturing ecosystem

- Reduced dependency on single-country sourcing

Explore OEM & ODM PCBA Manufacturing in Vietnam

2. SCSPCBA Vietnam PCBA Factory – Real Production, Local Teams

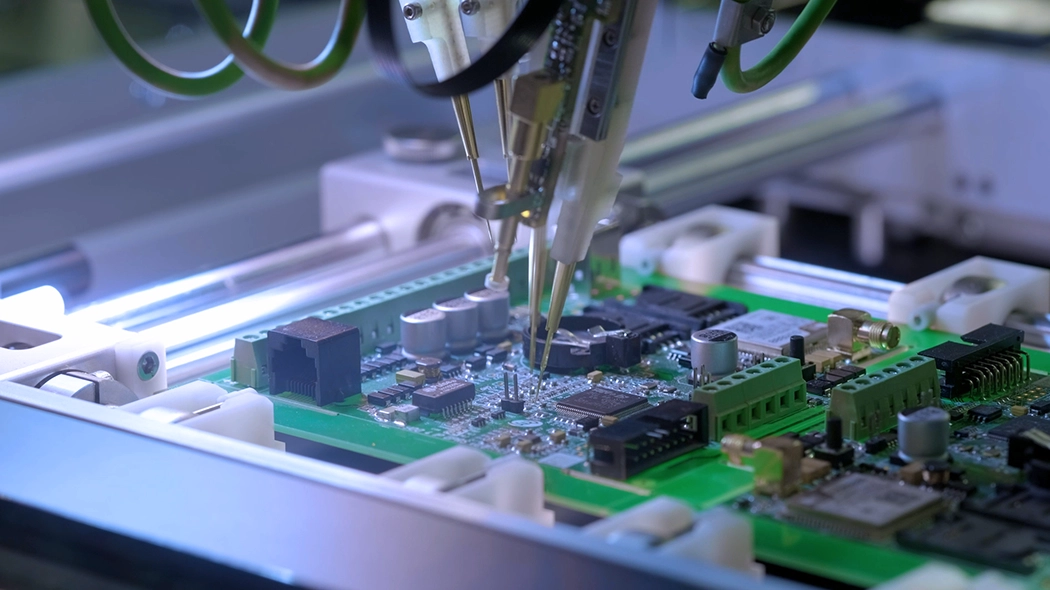

SCSPCBA operates a physical Vietnam PCBA factory with on-site production lines, engineering staff, and quality control teams.

This is not a sourcing office or virtual PCBA supplier, but a fully operational manufacturing facility built to support OEM and ODM PCB assembly services for global export markets.

As a professional PCBA factory in Vietnam, our facility is structured to deliver stable mass production, cost-efficient assembly, and consistent quality for international customers.

Verify Our Vietnam PCBA Manufacturing Capability

(1) Vietnam Factory Overview

Manufacturing Type: PCBA Assembly & System Integration

The Vietnam facility focuses on PCBA assembly and system-level integration, supporting:

- SMT assembly

- DIP insertion

- Mixed-technology PCB assembly

- Final assembly

This positioning allows SCSPCBA to act as a long-term PCBA supplier in Vietnam, especially for products entering stable or volume production phases.

(2) Supported Models: OEM / ODM / Turnkey PCBA

SCSPCBA Vietnam factory supports multiple manufacturing models to match different customer needs:

- OEM PCBA manufacturing

Build-to-print assembly based on customer-provided Gerber, BOM, and specifications. - ODM PCB assembly services

Engineering support including DFM review, BOM optimization, and design refinement. - Turnkey PCBA services

End-to-end support from PCB fabrication and component sourcing to assembly, testing, and delivery.

This flexibility enables SCSPCBA to be a full-scope PCBA supplier in Vietnam, offering services beyond assembly-only.

(3) Engineering Linkage: China–Vietnam Integrated System

One of SCSPCBA’s key advantages is its China–Vietnam integrated manufacturing system.

- China factories (Shenzhen / Jiangsu / Jiangxi):

Fast PCB fabrication

Prototyping PCB

Complex engineering changes - Vietnam PCBA factory:

Cost-optimized assembly

Stable volume production

Export-oriented fulfillment

All factories operate under unified engineering standards, documentation systems, and quality processes, ensuring seamless transfer from prototype to mass production.

SCSPCBA enables customers to prototype in China and scale production in Vietnam without changing suppliers.

(4) Export Focus: US, EU, and Global Markets

The Vietnam PCBA factory is designed for export-oriented manufacturing, supporting customers shipping to:

- United States

- European Union

- Other global markets

Key export advantages include:

- Compliance with international quality standards

- Stable documentation and traceability

- Experience with overseas logistics and customs coordination

This makes SCSPCBA a reliable Vietnam PCBA supplier for global OEMs and ODMs.

Start an Export-Ready PCBA Project

(5) Consistent Quality Across Regions

As a certified PCBA factory in Vietnam, SCSPCBA applies the same:

-

Process control standards

-

Quality inspection procedures

-

Engineering documentation systems

Customers benefit from consistent quality, predictable delivery, and reduced supply chain risk, even when production is transferred between regions.

3. Vietnam PCBA Factory vs China Factories (Shenzhen / Jiangsu / Jiangxi)

For global OEMs and ODMs, choosing between a Vietnam PCBA factory and China PCB manufacturing facilities is no longer just about price—it is about total landed cost, tariff exposure, and supply chain resilience.

SCSPCBA operates both, allowing customers to select the most cost-efficient manufacturing route.

(1) Tariff Advantage: Why Vietnam Reduces Import Duty Risk

One of the biggest advantages of a PCBA factory in Vietnam is lower tariff exposure when exporting to the US and EU.

- PCBA products assembled in Vietnam typically face lower or zero additional tariffs compared to certain China-origin electronics.

- For US-bound shipments, Vietnam-origin PCBA helps OEMs avoid Section 301 tariff risks applied to some China-manufactured electronics.

- For EU customers, Vietnam benefits from favorable trade agreements, reducing import duties for electronics assemblies.

Manufacturing PCBA in Vietnam can significantly reduce tariff-related costs for US and EU imports.

Evaluate Tariff-Saving PCBA Options

(2) Total PCBA Cost Comparison: Assembly Cost + Tariff + Logistics

When comparing PCBA cost, many buyers focus only on assembly price. In practice, total landed cost is what matters.

- Cost Structure Comparison

| Cost Factor | Vietnam PCBA Factory | China Factories |

|---|---|---|

| Labor & assembly | Lower | Higher |

| Tariff exposure (US/EU) | Low | Medium–High |

| Logistics | Stable | Stable |

| Total landed PCBA cost | Lower overall | Higher in tariff-sensitive markets |

For volume OEM and ODM projects, shifting assembly to Vietnam can reduce total PCBA cost by 10–25%, depending on product category and destination market.

Vietnam PCBA manufacturing often lowers total cost even if PCB fabrication remains in China.

(3) US Industrial Control OEM Reduces PCBA Manufacturing Costs through Vietnam PCBA Factory

Customer profile:

- Industry: Industrial automation

- Market: United States

- Annual volume: 30,000+ units

Challenge:

- Rising import tariffs on China-assembled PCBA

- Pressure to reduce unit cost without redesign

Solution:

- PCB fabrication remained in China (Shenzhen)

- PCBA assembly transferred to Vietnam factory

- Same BOM, same test strategy

Result:

- Tariff-related cost reduced by ~18%

- Overall PCBA unit cost reduced by ~15%

- No change in quality or delivery stability

See If Your Product Qualifies for Tariff Reduction

(4) When China Factories Are Still the Better Choice

China and Vietnam factories serve different stages of the PCBA lifecycle.

China factories remain ideal for:

- Early-stage R&D and prototyping

- Complex multilayer PCB fabrication

- High-mix, low-volume engineering builds

SCSPCBA helps customers choose the right location at the right stage, rather than forcing a single-country solution.

Get Location Recommendation from PCBA Experts

4. SCSPCBA Vietnam PCBA Factory Capabilities (OEM & ODM)

(1) PCB Assembly Capabilities

- SMT & DIP mixed assembly

- BGA / QFN / 0201 component support

- Lead-free & RoHS-compliant processes

- Medium to high-volume PCBA production

(2) OEM & ODM Support

- OEM: Build-to-print manufacturing

- ODM: Design assistance, DFM, BOM optimization

- Engineering change & lifecycle support

(3) Testing & Quality Control

- AOI inspection

- X-ray inspection (BGA)

- ICT & functional testing

- Aging & reliability testing

(4) Certifications & Standards

- ISO 9001

- ISO 13485 (medical OEM projects)

- IPC-A-610 compliant assembly

This positions SCSPCBA as a trusted ISO-certified PCBA factory in Vietnam for OEM and ODM customers.

5. Who Should Choose a Vietnam PCBA Supplier?

Below are the industries that benefit most from SCSPCBA’s Vietnam PCBA factory.

(1)Medical Electronics PCBA Manufacturing

Medical electronics demand strict quality control, full traceability, and long-term production stability. SCSPCBA’s Vietnam PCBA factory is structured to support regulated medical OEM manufacturing.

- Certifications & Compliance

ISO 13485 – Medical device quality management

ISO 9001 – Process and quality control

IPC-A-610 Class II / III (project-based) - PCBA Manufacturing Capabilities

Fine-pitch SMT for compact medical boards

BGA / QFN assembly for high-density designs

Lead-free and RoHS-compliant processes

Controlled BOM sourcing with lifecycle management - Equipment & Testing

AOI for solder joint inspection

X-ray inspection for BGA

Functional testing (FCT)

Aging and reliability testing - Typical Medical Applications

Patient monitoring systems

Diagnostic imaging control boards

Infusion pump PCBA

Portable medical devices

Vietnam PCBA manufacturing is ideal for medical electronics requiring ISO 13485 compliance and long-term supply stability.

(2)Automotive Electronics PCBA Manufacturing

Automotive electronics require high reliability, vibration resistance, and consistent volume production. SCSPCBA supports automotive-related PCBA programs in Vietnam for non-safety and functional modules.

- Certifications & Standards

ISO 9001

IPC-A-610

Automotive-grade process control (project-specific) - PCBA Manufacturing Capabilities

Mixed SMT & DIP assembly

High-reliability soldering processes

Support for automotive-grade components

Stable batch and volume production - Equipment & Testing

AOI & X-ray inspection

In-circuit testing (ICT)

Functional testing under load conditions - Typical Automotive Applications

Body control modules

Lighting control systems

In-vehicle display control boards

Sensor interface modules

Vietnam PCBA suppliers are suitable for automotive electronics requiring cost-efficient, high-reliability assembly.

(3)Industrial Electronics PCBA Manufacturing

Industrial electronics demand robust design support, long service life, and consistent quality. Vietnam PCBA factories are well suited for industrial OEM and ODM production.

- Certifications & Standards

ISO 9001

IPC-A-610 - PCBA Manufacturing Capabilities

Multilayer PCB assembly

High-current and power PCBA support

SMT & DIP mixed technology

ODM support including DFM and BOM optimization - Equipment & Testing

AOI inspection

Functional testing under simulated operating conditions

Burn-in testing for stability - Typical Industrial Applications

PLC control boards

Power supply modules

Motor drive controllers

Industrial HMI systems

Vietnam PCBA manufacturing offers stable, cost-effective solutions for long-lifecycle industrial electronics.

(4)Consumer Electronics PCBA Manufacturing

Consumer electronics benefit from cost optimization, scalability, and fast production ramp-up. SCSPCBA’s Vietnam PCBA factory supports volume consumer PCBA assembly.

- Certifications & Compliance

ISO 9001

RoHS / REACH compliance - PCBA Manufacturing Capabilities

High-speed SMT assembly

Ultra-fine pitch component placement

Cost-driven BOM optimization

Flexible volume scaling - Equipment & Testing

SPI (Solder Paste Inspection)

AOI inspection

Functional testing for end-user operation - Typical Consumer Applications

Smart home devices

Wearable electronics

Bluetooth and IoT devices

Power adapters and chargers

Vietnam PCBA suppliers are ideal for cost-sensitive consumer electronics with scalable volume needs.

6. Vietnam PCBA Factory FAQ

What is the MOQ for Vietnam PCBA manufacturing?

MOQ depends on BOM and assembly complexity. SCSPCBA supports low-volume OEM builds and scalable ODM production.

What is the typical lead time?

Lead time may vary depending on testing and component availability.

Do you provide turnkey OEM & ODM services?

Yes. As a full PCBA factory in Vietnam, we offer turnkey OEM and ODM services including design support, sourcing, assembly, and testing.

Are Vietnam factory processes aligned with China factories?

Yes. All Vietnam production follows the same quality system, standards, and engineering oversight as SCSPCBA’s China factories.

Why SCSPCBA Is More Than a Vietnam PCBA Factory

SCSPCBA integrates:

Vietnam PCBA factory – cost-efficient OEM & ODM assembly

China factories (Shenzhen / Jiangsu / Jiangxi) – fast prototyping, advanced PCB fabrication

This hybrid manufacturing model helps OEMs and ODMs:

Reduce total cost

Improve delivery stability

Scale production with confidence

Get a Vietnam OEM & ODM PCBA Quote Today