How Quality Standards and Testing Ensure Reliable PCB Assembly Manufacturing

In PCBA manufacturing, reliability is the result of rigorous PCBA quality control, standardized processes, and comprehensive electronic assembly inspection. As electronic products move toward higher density, automotive-grade durability, and global compliance, manufacturers must align with internationally recognized PCB testing standards and system certifications such as ISO 9001, ISO 14001, ISO 13485, IATF 16949, IPC-A-610, UL, CE, and RoHS.

1. Why International Standards Matter in PCBA Quality Control

(1) Unified Technical Specifications

Global standards such as IPC-A-610 (Electronic Assembly Acceptance Standard) and IPC-6012 (Rigid PCB Performance Specification) provide clear and quantifiable requirements for solder joint quality, material selection, circuit board thickness, tolerance ranges, and electronic assembly inspection methods.

These specifications ensure that different production lines and factories can follow consistent processes, significantly reducing human error and production variations.

Examples:

- IPC-A-610 clearly defines solder joint morphology, wetting angle, and solder amount range.

- IPC-7711/7721 specifies rework and rework procedures to prevent unregulated repairs from causing hidden defects.

These standards are a core component of PCB testing standards and significantly improve product consistency.

(2) Enhanced Reliability

Industry standards require PCBAs to undergo a series of stress tests, including:

- Temperature cycling (-40°C ~ 125°C)

- Mechanical vibration/shock

- High humidity operating conditions (85% RH)

- Continuity/insulation resistance testing

- X-Ray, ICT, ATE full-process electronic assembly inspection

These tests ensure that PCBAs can achieve a lifespan of 8–10 years or more, even when used in high-load scenarios such as high-power inverters, automotive electronics, and communication base stations.

(3) Facilitating International Circulation

Different countries have different market access rules, such as:

- Europe: CE + RoHS (Environmental and Safety Regulations)

- USA: UL (Product Safety and Flammability Standards)

- Automotive Industry: IATF 16949 (Automotive-Grade Manufacturing System)

By meeting these regulations, companies can achieve cross-border circulation of PCBA products without being intercepted or returned due to non-compliance with certifications.

(4) Driving Quality System Construction

Standards such as ISO 9001 (Quality Management System) emphasize:

- Full-process documented management

- Data-driven monitoring of process capabilities

- Batch traceability

- Continuous improvement

These mechanisms can improve production stability, shorten delivery cycles, and reduce defect rates. For example:

- Monitoring solder paste printing deviations through SPC (Statistical Process Control) can reduce defect rates by 30–60%.

- MES data tracking enables 100% batch traceability.

(5) Ensuring Manufacturing Repeatability

Without universal benchmarks such as IPC, ISO, and UL, PCBA manufacturing will suffer from:

- Inconsistent component soldering quality

- Significant differences in material reliability

- Inconsistent performance of the same design produced in different factories

- Inability to maintain consistency in large-scale production

Therefore, industry standards are a crucial foundation for achieving globalized manufacturing, reducing failure rates, and improving consistency.

2. Internationally Recognized PCBA Certifications & Quality

(1) ISO 9001 — Quality Management System

Industry Usage:

Applicable to all electronics and manufacturing industries, including consumer electronics, industrial control, automotive, power equipment, renewable energy, etc.

PCBA Manufacturing Requirements:

- Process Consistency: Ensure standardized procedures (SOPs) for soldering, surface mount technology (SMT), testing, packaging, etc.

- Traceability: Each batch of PCBA must have traceable process, material, and procedure records.

- Document Control: BOM, Gerber, and process parameters must be strictly version-managed.

(2) ISO 14001 — Environmental Management System

Industry Usage

Applicable to industries with strict environmental requirements for the supply chain, such as green energy, home appliance manufacturing, and North American/EU electronics brand supply chains.

PCBA Manufacturing Requirements:

- Chemicals, cleaning agents, fluxes, etc., must comply with environmental protection regulations.

- Factory must have standardized treatment processes for waste gas, wastewater, solder dross, etc.

- Energy Conservation and Continuous Improvement Mechanisms

(3) ISO 13485 — Medical Device Quality System

Industry Usage

Medical electronics: ECG monitors, infusion pumps, imaging equipment, blood glucose meters, health monitoring equipment, etc.

PCBA Manufacturing Requirements

- Medical-grade risk management (FMEA) process

- 100% AOI or X-ray inspection of critical solder joints

- Strict electronic assembly inspection and process record keeping (up to 5–10 years)

- Sterility, reliability, and material traceability must be controlled

(4) IATF 16949 — Automotive Quality Management Standard

Industry Usage

Automotive electronics and new energy industries: BMS, electric drive controllers, vehicle cameras, ADAS, vehicle infotainment systems, etc.

PCBA Manufacturing Requirements

- Strict process capability index (e.g., Cpk ≥ 1.33)

- Critical solder joints must meet AEC-Q standard components

- High reliability verification for heat resistance, vibration resistance, and humidity resistance

(5) IPC Standards

Industry Usage

All electronics manufacturing fields, especially those with specific requirements for solder joint grades.

PCBA Manufacturing Requirements

- IPC-A-610: Defines solder joint classes

- IPC-6012: PCB structure, electrical performance, and copper thickness requirements

- IPC-7711/21: Rework and repair rules

- Solder joint morphology, solder amount, and pad temperature profiles must fully comply with the collective specification.

(6) UL Certification

Industry Usage

North American market, smart home appliances, power products, battery management systems (BMS), inverters, etc.

PCBA Manufacturing Requirements

- PCB substrate must meet flame retardant standards (most common: UL94 V-0)

- Electronic components must comply with safety distance, creepage distance, and fire-resistant structural requirements.

- UL796: Used for complete PCB/PCBA structural certification.

(7) CE Marking

Industry Usage

All electronic devices exported to the EU: consumer electronics, industrial control, home appliances, medical accessories, smart devices, etc.

PCBA Manufacturing Requirements

- Meet EMC electromagnetic compatibility requirements (EN 55032 / EN 61000 series)

- Meet LVD Low Voltage Directive requirements

- Risk assessment and Technical Documentation (TDF) preparation are mandatory.

(8) REACH Regulation

Industry Usage

All PCBA electronic products exported to the EU.

PCBA Manufacturing Requirements

- Prohibition of REACH Substances of Very High Concern

- Compliance reports are required for PCB boards, solder paste, and cleaning agents.

- Supply chain requires Material Safety Data Sheets

(9) RoHS Directive

Industry Usage

Almost all electronic manufacturing industries and end-use equipment (mandatory in almost all of Europe and the US).

PCBA Manufacturing Requirements

- Restrictions on 10 hazardous substances: Lead, Cadmium, Mercury, Cr6+, PBB, PBDE, DEHP, etc.

- Materials supply chain must provide a Declaration of Conformity (CoC).

- Reflow soldering temperature profiles must be adjusted to accommodate lead-free solder (e.g., SAC305).

These standards collectively form the quality foundation of modern electronics manufacturing, enabling PCBA products to possess:

- Repeatable manufacturing

- Global market access

- High reliability and traceability

- A complete PCBA quality control system

- Meeting stringent electronic assembly inspection requirements

More importantly, these standards enable printed circuit board assembly manufacturers to significantly reduce defect rates, shorten development cycles, and ensure products can withstand extreme environments—crucial for high-risk industries such as automotive, medical, and energy.

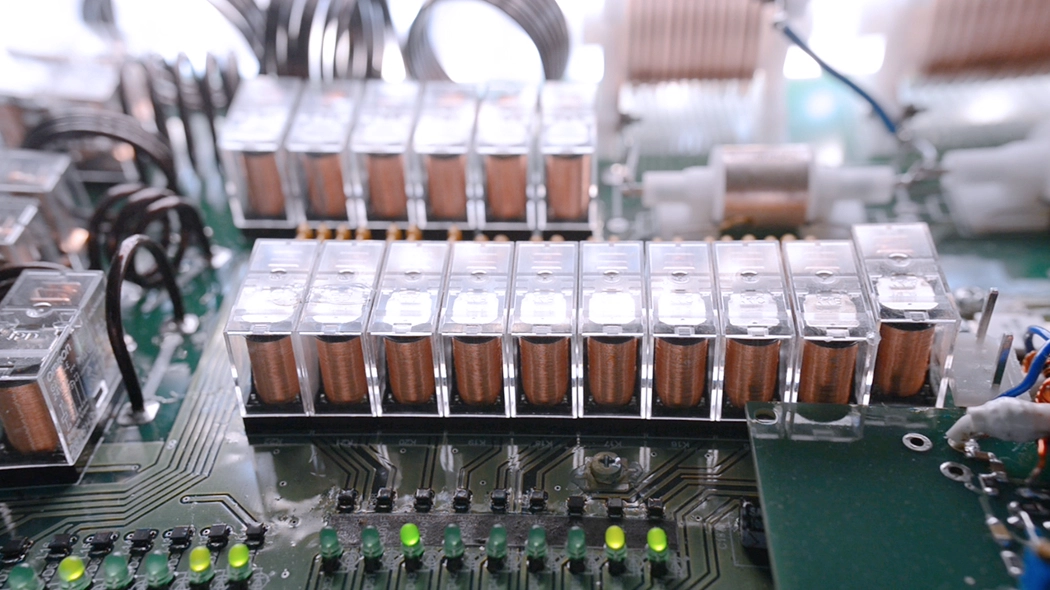

3. Printed Circuit Board Testing Methods

(1) AOI – Automated Optical Inspection

AOI is the most fundamental and critical visual inspection technology in printed circuit board production, used to ensure the accuracy of solder joint structure, component polarity, silkscreen matching, and solder quantity.

Modern high-definition AOI equipment typically has a resolution of 10–20 μm, capable of identifying minute defects such as bridging, insufficient solder, tombstoning, misalignment, and reverse mounting.

For high-density assembly (HDI PCB), 0201 packages, and automotive electronics, this inspection method is the first step in maintaining PCBA quality control, ensuring consistent visual and structural performance.

(2) X-ray Inspection

X-ray inspection is the industry-standard method for evaluating invisible solder joints (such as BGA, QFN, LGA).

Its core metrics include:

- Void ratio (bubble/void rate) is typically required to be below 20–25%.

- Solder ball coplanarity, solder joint thickness, and internal crack identification.

- For high-current applications (energy storage, inverters, motor drives), a lower void ratio results in higher heat resistance.

(3) In-Circuit Test ( ICT )

ICT (In-Circuit Testing) is considered one of the most effective methods for electronic assembly inspection, verifying each component point-by-point using a bed-of-pin fixture or test jig:

- Actual values of resistors, capacitors, and inductors

- Open circuits, short circuits

- Diode/transistor polarity

- IC pin solder joint integrity.

ICT test ensure production consistency and traceability, particularly suitable for high-volume PCBA manufacturing (e.g., automotive, consumer electronics, industrial control).

(4) Flying Probe Test

Flying probe testing is fixture-free and suitable for:

- Small batch production

- Rapid prototyping

- High-level & HDI PCBAs

Typical engineering standards include:

- Connectivity testing requirements: On-resistance < 10 Ω

- Point-by-point excitation and measurement, improving adaptability to layout changes

- Supports electrical verification of IC open/short circuits, power rail stability, and component reverse polarity

Compared to ICT, flying probe testing is slower but extremely flexible, making it a core testing method in R&D and pilot production phases.

(5) Functional Test (FCT)

FCT (Functional Testing) is the ultimate test standard to verify whether a PCBA can function properly in a real-world usage environment.

Common functional verifications include:

- Power-On Sequence

- Signal Communication (CAN, RS485, UART, SPI, I2C, etc.)

- Load Response and Real-Time Control Logic

- Button, Sensor, Display, and Communication Module Functions

- Generally configured with Pass/Fail logic, and may include:

- Multiple Power Cycles

- High and Low Temperature Chamber Stability Testing

- Dynamic Signal Simulation

FCT is an indispensable component in high-reliability industries such as energy storage inverters, BMS, smart grid equipment, and medical electronics.

4. How Quality Standards Affect Each Stage of PCBA Manufacturing Process

Quality standards permeate the entire PCB assembly and manufacturing, from raw material selection to box build assembly testing. Through clear specifications, testing requirements, and process parameters, they directly affect the yield, reliability, and final product performance at each stage.

(1) Raw Material Stage

Quality standards screen qualified materials through rigorous incoming quality control (IQC) to prevent defects from entering the production line. For example:

- PCB board: Must meet the standards for appearance (no warping, cracks), dimensions (warping ≤ 0.5%) and electrical performance (conductivity ≤ 50mΩ)

- Components Supply Chain: Leads must be free of oxidation, packages must be free of cracks, and solderability of solder terminals must pass a 235℃ immersion soldering test (soldering rate ≥ 90%)

- Solder paste: Viscosity controlled at 200-300Pa·s, metal content 40%-50%, to avoid soldering defects caused by material issues

(2) Production and processing stage

- SMT placement: Placement accuracy error ≤ 0.02mm, AOI inspection coverage 100%, which can reduce cold solder joints and incorrect components, and improve the placement yield to over 99.5%

- Reflow soldering: The oven temperature profile must match the heat resistance parameters of the components to avoid overheating damage or insufficient soldering

- DIP insertion: The wave soldering temperature is controlled at 250±5℃, and the lead length is consistent to ensure full solder joints and reduce the risk of short circuits.

(3) Testing and Quality Control Stage

Quality standards ensure product compliance with design requirements through multi-dimensional testing:

- AOI Inspection: Automatically identifies solder joint defects (such as bridging, insufficient solder), replacing manual inspection and improving efficiency by 300%.

- Functional Testing: Simulates actual working conditions to verify functionality; the customer provides test codes to ensure 100% functional compliance before delivery.

- Environmental Testing: High and low temperature (-40℃~85℃), vibration testing to verify stability under extreme conditions.

(4) Packaging and Traceability Stage

Quality standards require PCBAs to be stored separately in anti-static packaging, with humidity controlled ≤60%, and information such as material batch number and production equipment recorded to achieve full-process traceability.

5. Impact of Quality Standards in Different Industries on PCBA Costs

In PCB fabrication and assembly, different application areas (consumer electronics, industrial control, medical devices) impose completely different requirements on materials, processes, testing, and reliability, resulting in significant cost differences.

(1) Consumer Electronics

- Raw Material Costs: Using conventional FR-4 materials, no special certification is required; material costs account for approximately 40%–50%.

- Process Complexity: circuit board manufacturing processes are mainly conventional SMT, with relatively low requirements for board heat resistance, electrical performance, and reliability; therefore, process costs are more controllable.

- Testing Costs: Primarily sampling inspection, with basic AOI testing; testing costs account for approximately 5%–8%.

- Rework and Return Rate Costs: Typically in the range of 0.5%–1%.

(2) Industrial Control

- Raw Material Costs: Using high-Tg PCBs, high-temperature resistant components, and implementing stricter board thickness design and impedance control increases material costs by 20%–30%.

- Process complexity: High-temperature welding stability and high-precision stacking must be guaranteed, typically increasing process costs by 15%–25%.

- Inspection costs: Widespread use of AOI + ICT full inspection to reduce batch defect risks increases inspection costs by 10%–20%.

- Rework and return rate costs: Typically lower than 0.2%–0.5%, rework costs are significantly higher than in consumer applications.

(3) Medical Electronics

- Raw material costs: Requires the use of components with special medical certifications (such as UL94 V-0, ISO 13485 environmental materials), increasing material costs by 50%–80% compared to consumer-grade products.

- Manufacturing Complexity: To meet the requirements of sterility, safety, and high durability, the manufacturing process must employ end-to-end anti-static, anti-corrosion, and cleanroom environment control, typically increasing engineering costs by 30%–60%.

- Testing Costs: 100% inspection using AOI + X-ray + functional testing increases testing costs by 100%–150% compared to conventional products.

- Rework and Return Costs: Medical-grade products have extremely stringent failure rate requirements, typically below 0.01%. Even the smallest deviation can affect clinical safety, therefore rework and return costs can reach 50%–80%.

Overall, the key differences between consumer electronics, industrial control, and medical electronics are: Medical-grade products require the highest-grade materials and comprehensive testing; industrial-grade products prioritize long-term stability, temperature resistance, and reliability; consumer-grade products prioritize cost efficiency and market competitiveness. Without international standards such as ISO, IPC, and UL as unified technical benchmarks, different suppliers cannot achieve consistent quality, and large-scale cross-regional manufacturing is difficult.

6. Ready to Build High-Reliability PCBA With Certified Quality Standards?

Our engineering team provides ISO-certified manufacturing, IPC-class workmanship, complete testing, and full traceability for industrial, automotive and renewable-energy applications.