Medical Electronics Assembly: Building Stable and Accurate PCBA for Healthcare

Imagine a surgeon relying on a cardiac monitor during a complex procedure, or a diabetic patient trusting their continuous glucose reader for a life-saving dose of insulin. In these critical moments, the silent hero ensuring accuracy and reliability is often the printed circuit board assembly at the heart of the medical device. At SCSPCBA we understand that medical PCB assembly isn’t just about components and solder; it’s about patient safety and trust.

In the healthcare industry, medical PCB assembly plays a critical role in ensuring device accuracy, stability, and safety. Whether it is an oxygen concentrator circuit board, a pulse oximeter PCB, or a more complex PCBA medical device, reliability in medical electronics assembly directly affects patient outcomes. Choosing the right medical PCB board manufacturer is therefore vital to achieving both precision and compliance in medical device production.

The Critical Importance of Circuit Boards in Medical Electronics Assembly

Unlike consumer electronics, medical device electronics assembly must meet exceptionally strict regulations and safety standards. High-quality medical device PCBA ensure the accuracy, stability, and safety of medical devices through the following:

1. Ensuring Diagnostic and Monitoring Accuracy

Medical devices rely on high-precision signal transmission. Wearable ECG monitors and continuous glucose monitoring systems, for example, require amplification, filtering, and digitization of minute biological signals. Professional medical electronics assembly ensures signal transmission errors within ±10% through sophisticated circuit design employing multi-layer PCBs and micro-component assembly. This guarantees stable power transmission and signal integrity, ultimately ensuring diagnostic accuracy.

2. Enhancing Device Stability for Demanding Environments

Medical devices often face harsh environments including high-temperature sterilization (134°C steam) and chemical corrosion. Medical grade PCB assembly utilizes high-temperature-resistant substrates (such as high-Tg PCBs) and biocompatible materials. Even after 500 cycles of high-temperature sterilization, these materials maintain insulation resistance above 10¹⁰Ω, ensuring reliable long-term performance in critical care settings.

3. Ensuring Patient Safety Through Compliance

Medical PCB manufacturing and assembly complies with ISO13485 and other stringent medical standards. Assembled circuit boards for implantable devices (such as pacemakers and neurostimulators) must withstand temperature fluctuations and corrosive effects from body fluids. Advanced manufacturers use copper layers protected by titanium nitride coatings, which in simulated body fluid immersion tests show a corrosion rate of only 0.1μm/year—far superior to conventional materials.

4. Optimized PCB Layout for Critical Applications

Critical circuits in devices such as infusion pumps and cardiac monitors utilize dual-redundancy design principles. This approach has enabled modern infusion pumps to achieve mean time between failures (MTBF) of 50,000 hours or more, meeting the rigorous demands of intensive care settings. Professional medical electronics assembly manufacturers combine design optimization with rigorous testing to ensure safe operation.

5. Electromagnetic Interference Management

Electromagnetic radiation from equipment such as MRI machines and electrosurgical units can interfere with sensitive medical device signals. Medical PCBA incorporates strategic grounding schemes with copper tape at least 0.5mm wide to separate analog and digital circuits, while shielding layers protect sensitive measurement circuits in monitoring devices.

Key Methods for Reliable Medical PCB Assembly and Manufacturing

Key methods for reliable medical PCBA include rigorous design control, high-precision manufacturing processes, precision assembly techniques, and rigorous quality testing. They are as follows:

1. Advanced Medical PCB Design Stages

- Meeting Regulatory Standards: Complying with medical device manufacturing standards such as ISO 13485 and IPC-6012 Class 3, and ensuring biocompatibility (e.g., using non-toxic materials).

- Incorporating High-Density Interconnect Technology: Utilizing microvias and fine-line designs (e.g., trace widths less than 0.003 inches) optimizes signal transmission and thermal performance.

- Circuit Design and Verification: Proper PCB layout online, thermal management, and EMC shielding are crucial for reducing failure rates. By optimizing medical device circuit board design, manufacturers can ensure higher precision for equipment such as diagnostic instruments and monitoring systems.

2. High-Precision Medical PCB Board Manufacturing Process

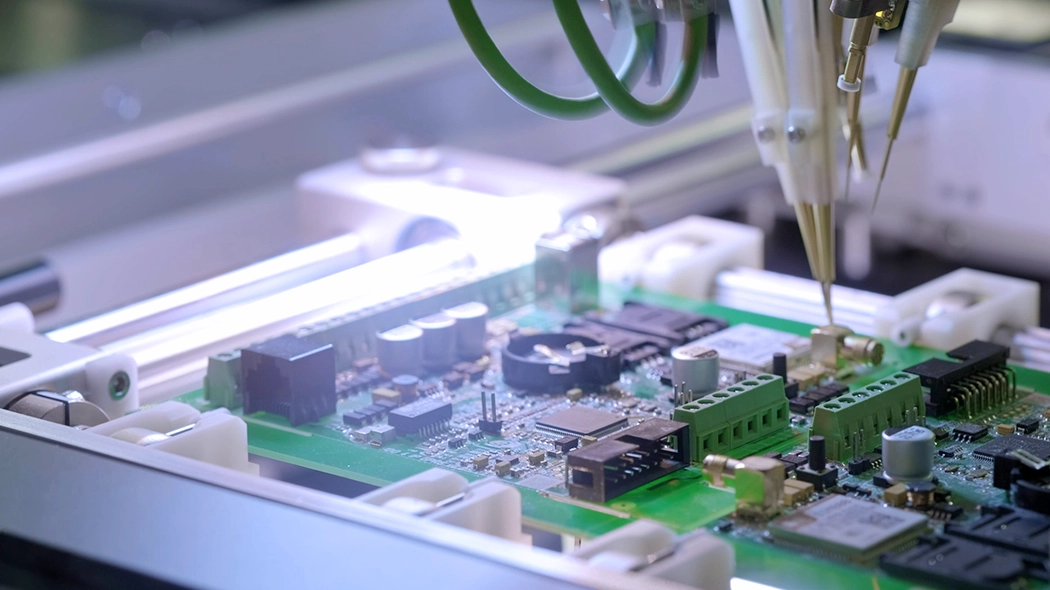

Professional medical PCB assembly manufacturers rely on automated SMT placement and nitrogen reflow soldering to minimize defects. Using a dust-free, anti-static environment, they control drilling and etching processes to an accuracy of ±0.01mm. These processes enhance solder joint strength and ensure the long-term stability of medical PCBAs.

3. Material Selection for Medical Applications

For medical grade PCB applications, advanced substrates such as high-TG FR-4, polyimide, ceramic PCBs, and high-temperature resistant substrates (such as FR-4 Tg170 substrate) are preferred. Sourcing from traceable suppliers ensures that each printed circuit board assembly medical is manufactured with reliable components.

4.Precision Printed Circuit Assembly Technology

- Surface Mount Technology: Utilizes high-precision SMT machinery (positioning accuracy ±0.01mm) and optimized solder paste application with stencils to ensure precise component placement.

- Nitrogen Reflow Oven Soldering: Controlled temperature profiles (e.g., a peak of 245°C for lead-free solder) prevent thermal damage to components.

- Conformal Coating: Polyurethane or silicone sprays are applied to critical areas to enhance moisture and corrosion resistance.

Comprehensive Quality Testing and Inspection

Medical PCBA products undergo rigorous testing to ensure safe operation under various clinical conditions:

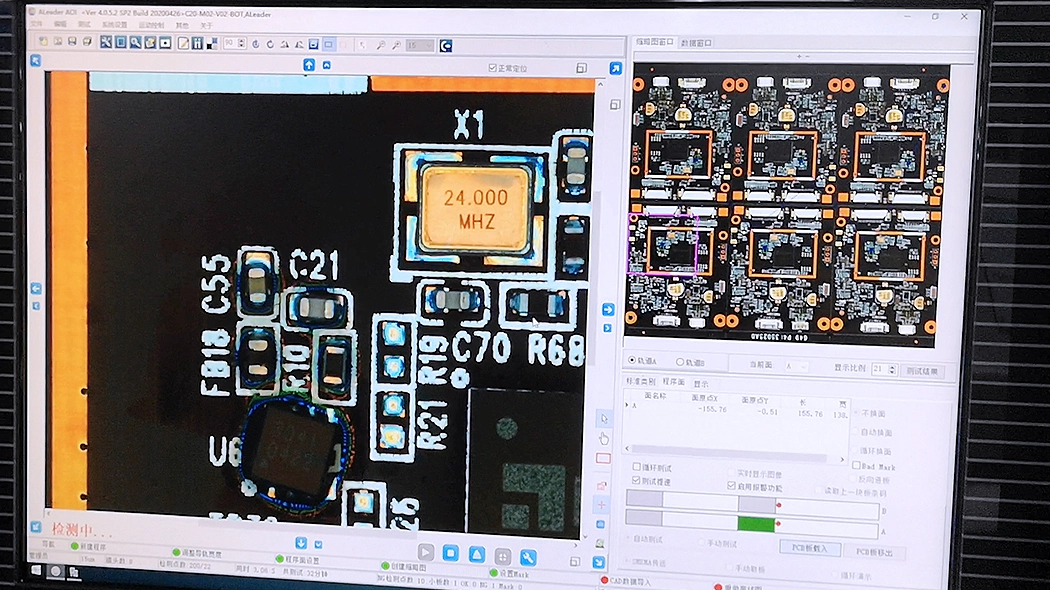

1. Automated Optical Inspection (AOI)

Utilizing high-resolution industrial cameras and deep learning algorithms, 3D inspection of medical PCBAs is completed within 0.5 seconds. AOI systems detect solder balls as small as 0.01mm² and component offsets of 0.05mm, significantly reducing defect rates.

2. In-Circuit Testing (ICT)

Spring probe arrays construct virtual multimeter networks that accurately measure 2,000 nodes in 30 seconds. This technology detects resistance deviations as small as 0.001Ω and capacitance fluctuations of 1pF, ensuring stability in extreme medical environments.

3. Functional Testing (FCT)

Using customized fixtures to simulate actual operating scenarios, the performance of circuit board assembly is verified under harsh conditions such as voltage fluctuations and sudden load changes. For example, an oxygen concentrator circuit board exposed a motor driver chip to an abnormally high temperature of 85°C during this process, avoiding the risk of a mass recall.

4. Environmental Reliability Testing

Comprehensive testing includes:

-

- High-temperature storage (85°C/85% RH, 1,000 hours)

- Temperature cycling (-40°C to +85°C, 1,000 cycles)

- High-temperature power-up (125°C/168 hours) to identify potential defects

5. Accelerated Aging Validation

Medical device electronics assembly must remain stable in challenging environments including:

-

- EMI from surgical equipment in operating rooms

- Repeated sterilization procedures in clinical settings

- Body fluid exposure for implantable devices

Accelerated aging tests simulate these extreme conditions to identify potential failures before devices reach patients.

Real-World Applications of Medical PCB Assembly Technology

1. Precision Diagnostic Equipment

Advanced medical electronics assembly enables high-resolution imaging systems including portable ultrasound devices and digital X-ray systems, where signal integrity directly impacts diagnostic capability.

2. Wearable Medical Technology

Medical printed circuit board assembly manufacturering miniaturization has enabled a new generation of wearable devices including:

-

- Continuous glucose monitoring systems

- Patch-based cardiac monitors

- Smart infusion pumps with dose accuracy verification

3. Patient Monitoring Systems

Modern patient monitoring systems rely on high-reliability medical electronic assembly for:

-

- Multi-parameter vital signs monitoring

- Wireless telemetry systems

- Smart hospital integration platforms

4. Laboratory Automation Equipment

Precision medical grade circuit board applications in laboratory equipment include:

-

- Automated sample analysis systems

- DNA sequencing instrumentation

- Diagnostic test automation platforms

Selecting the Right Medical PCB Assembly Manufacturers

When requesting medical PCB assembly quotes, consider these critical factors:

- Certifications and Compliance: Verify ISO13485, RoHS, UL certifications, and specific medical device regulatory experience

- Medical Design Expertise: Evaluate experience with complex medical device electronics assembly projects and design for manufacturability capability

- Full one-stop PCBA Service Capability: Assess end-to-end solutions from design support to mass production and testing

- BOM and Supply Chain Transparency: Ensure component traceability and supply chain resilience

Partnering with an experienced medical printed circuit board assembly manufacturer ensures your products not only meet regulatory requirements but also achieve faster time-to-market with enhanced reliability.

Frequently Asked Questions (FAQs) About Medical PCB Assembly

Q: What is the biggest difference between commercial and medical-grade PCB assembly?

A: The key difference lies in the extreme rigor of testing, documentation, and traceability. Medical-grade assembly must comply with stringent standards like ISO 13485 and IPC-A-610 Class 3, ensuring zero defects and long-term reliability in life-critical environments.

Q: How long does it typically take to get medical PCB assembly quotes?

A: Standard medical PCB assembly quotes are typically provided within 10 seconds. This AI-powered online quote system, developed independently by the scspcba technical team, requires only the complete Gerber files, BOM, or assembly file to receive an instant quote within seconds. For complex projects requiring an in-depth design for manufacturing (DFM) review, please contact us for an in-depth consultation within 24 hours.

Q: Can you handle both prototype and full-scale production for medical devices?

A: Absolutely. We specialize in a seamless transition from low-volume, rigorous medical electronic assembly for prototyping and clinical trials to high-volume, certified manufacturing for market launch.

Q: What documentation do you provide for regulatory submissions?

A: We provide comprehensive documentation packages, including a Certificate of Conformance (CoC), full material declarations (FMD), IPC-6012 reports, and traceability records for every component, which is crucial for FDA and other regulatory approvals.

Conclusion

With increasing demand for advanced healthcare technologies, medical electronics assembly has become indispensable for device accuracy, stability, and long-term performance. From medical grade PCB applications to complex PCBA medical devices, selecting the right assembly partner is crucial for success. By focusing on precision, compliance, and reliability, manufacturers help ensure that medical electronics improve patient safety and enhance healthcare outcomes worldwide.

For medical PCB assembly quotes or to discuss your specific medical device electronics assembly requirements, contact our expert team today to learn how our capabilities can support your innovative medical devices.