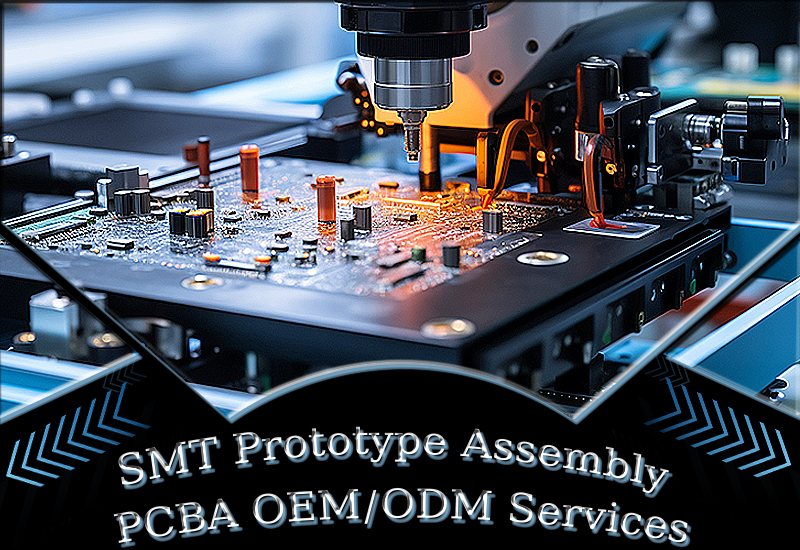

SMT Prototype Assembly And Printed Circuit Assembly OEM/ODM Services

In the fast-paced world of electronics manufacturing, surface mount technology prototype assembly and one-stop PCBA services are essential for printed circuit board manufacturers who pursue speed, quality, and efficiency. Whether launching a new product or scaling up production, a reliable PCBA partner can make a difference.

1. Why Choose One-Stop PCBA Services?

At SCSPCBA, we offer a fully integrated solution that covers the entire PCBA process:

-

PCB layout and PCB board fabrication

-

Component sourcing

- BOM management & Supply Chain

-

Functional testing and quality assurance

-

Packaging

This end-to-end approach allows you to focus on your core business while we handle the complexity of printed circuit assembly manufacturing.

2. OEM & ODM Manufacturer: From Idea to Execution

SCSPCBA offers OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) services tailored to your unique project needs.

- OEM Services (Original Equipment Manufacturing):

High-volume, standardized PCB board production based on customer-supplied PCB designs and specifications. - ODM Services (Original Design Manufacturing):

End-to-end support includes PCB board design, electronic components, PCB layout online, PCB prototyping, PCB board soldering, assembled circuit board, PCB board testing, box build assembly and mass production.

Whether you have a ready design or just a concept, our team can turn it into a working, market-ready product.

● Why Choose SCSPCBA Printed Circuit Board Manufacturers?

- 4 smart circuit board manufacturing factories in China and Vietnam with scalable production lines

- ISO9001, IATF16949, ISO13485, IPC-A- 610, RoHS & REACH certifications

- Expertise in industrial control, medical electronics, automotive electronics, wearable electronics, and smart home

- Fast SMT prototype assembly, full turnkey printed circuit assembly solutions

- A dedicated R&D team for circuit design and PCB board production innovation

- Strong global supply chain with genuine components sourcing

● SCSPCBA Core Capabilities

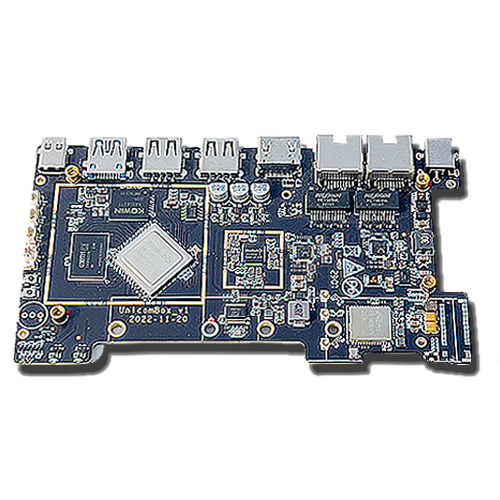

- PCBA Services: PCB programming, PCB component sourcing, SMT surface mount, DIP, PCB board testing, Box build assembly

- OEM Capabilities: Mass manufacturing, BOM management

- ODM Capabilities: Custom circuit design, Surface mount assembly

- Supported Boards: Single Layer PCB, Double Layer PCB, Multilayer PCB, HDI PCB, Rigid-Flex PCB, High-frequency PCB, Ultra-High-Layer PCB, Aluminum PCB,

- Ceramic PCB, Thick Copper PCB, High-Tg PCB, Flexible PCB

- Applications: Wearable Electronics, Industrial Control, Medical Electronics, Smart Devices, Automotive

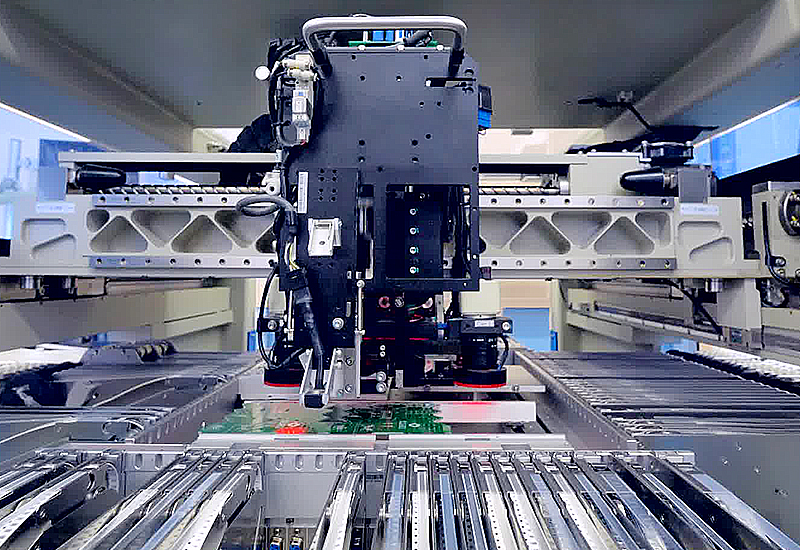

3. SMT Assembly Technology

Below is a visual summary of SCSPCBA technical strengths in surface mount technology :