It Only Takes Three Steps to Reduce PCBA Cost By 30%. You Can Also Do This

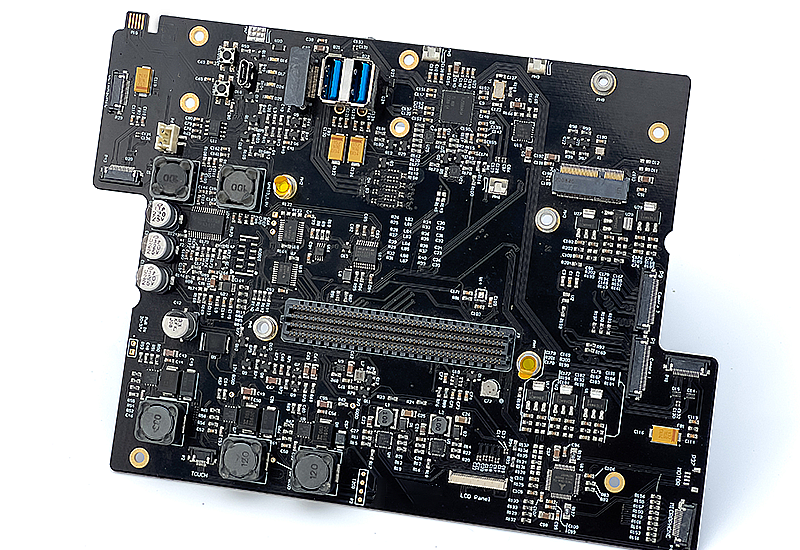

Behind electronic products are sophisticated and complex circuit boards, which are like the nerve center of electronic devices, carrying the task of transmitting current and signals. Today, let us step into the world of circuit board production and reveal the secrets to reduce the manufacturing cost of printed circuit board assembly.

PCB Assembly and Manufacturing Costs Are Higher Than Expected

Smart Home Pioneers, the client, is an innovative enterprise focusing on smart home products. Its core product is a smart control panel that integrates Wi-Fi communication, touch recognition and voice control functions. As the hub of the entire home system, the main control board of the panel is relatively complex in design, covering multiple functional modules such as communication module, power management module, and human-computer interaction interface. In the prototype stage, the product ran stably and performed well, and the customer was confident in it. But once it entered the mass delivery stage, the problem was exposed – the manufacturing cost of the single-board circuit board was nearly 35% higher than expected, which not only compressed the profit margin but also directly affected the market pricing of the product at the retail end.

After in-depth analysis, it was found that the customer lacked a cost control strategy in the formulation of the BOM list, the component models were mostly imported brands, the supply cycle of some materials was long, and the purchase price fluctuated sharply, increasing the overall material cost. The PCB design is not conducive to manufacturing, resulting in complex processes, reduced yields, and unnecessary manufacturing costs. In addition, the SMT manufacturing link also increases the difficulty of processing and labor costs due to the non-uniform material packaging. Faced with these challenges, the customer decided to introduce a partner with BOM optimization and full-process PCBA service capabilities – the SCSPCBA team. Together, they focused on circuit board design, electronics components selection, printed circuit board production process and other aspects, and successfully reduced costs by nearly 30%.

1. PCB Design Optimization for Cost-Effective PCBA Manufacturing Process

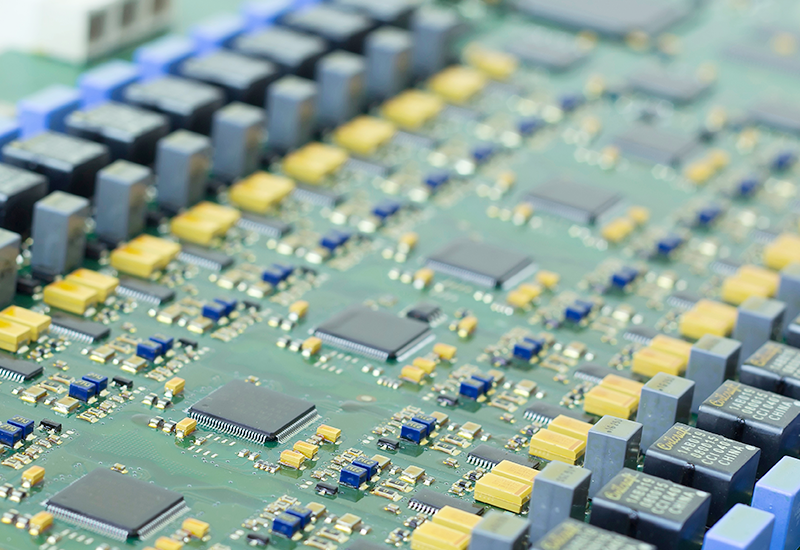

In printed circuit board assembly, the optimization of PCB board design is often underestimated, but it is the core factor that determines the manufacturing cost and yield of products. A successful PCB design optimization can not only reduce the cost of each board by a few yuan to more than ten yuan, but also improve the overall production line efficiency and reduce the rework rate.

(1) Multilayer PCB layer number control

The customer’s original solution uses a 6-layer multilayer board design. Although there is no problem with the functional implementation, the signal integrity and anti-interference requirements are not high. We re-layout the wiring, merge part of the power layer with the signal layer, and successfully simplify it to a 4-layer structure after optimizing the routing path, which not only ensures the electrical performance, but also directly reduces the pressing process and material costs by about 20%.

(2) PCB material replacement

The original design uses a high-Tg high-frequency board, which is suitable for high-end high-speed communication products, but it is “overperforming” for this smart home control motherboard. As an experienced ceramic PCB manufacturer and PCBA supplier, we also evaluate when high-thermal conductivity ceramic boards or standard FR4 materials are most cost-effective for a given application. In this case, we recommended using FR4 to significantly reduce raw material costs without affecting the function.

(3) Hole position standardization

The various sizes of vias in the original design are unified into standard sizes to avoid special drilling, reduce drilling time, and improve the consistency and processing efficiency of SMT assembly

Through these three optimizations, the core functions of the product are not changed, and significant cost control goals are achieved in circuit design alone.

2. Replacement of Electronic Components in Automotive PCB Assembly and Other Applications

In the BOM list, there are often a lot of “hidden costs”. The customer’s main control board selected a lot of “brand-specified” components in the initial design stage, such as TI’s voltage regulator chip, ST’s MCU, and imported capacitors and resistors. Although the performance is stable, it also makes the purchase price of the entire order high, and is frequently restricted by the delivery date and long procurement cycle.

The replacement component evaluation mechanism was launched after the intervention of the SCSPCBA component engineering team. Only three things were done, and the cost was reduced.

This approach is not limited to smart home projects — in automotive PCB assembly and other industrial electronics, similar BOM optimization and design streamlining help clients meet strict reliability standards while reducing overall manufacturing costs.

(1) Replace the high-priced chip on board

Replace some imported brand chips with higher unit prices with domestic alternative models compatible with functions, similar performance, and complete certifications.

The original design used imported-brand MCUs with high unit prices and unstable supply cycles. We recommend using domestic MCUs with equivalent performance (compatible pin packaging). Through actual measurement and verification, the cost is directly reduced by 18% without sacrificing operating efficiency.

For example, an imported LDO chip with a unit price of 1.8 yuan was eventually replaced by a domestic brand with a unit price of only 0.65 yuan, and the supply was stable for a long time. Such optimization was applied in more than 10 places in the entire BOM list, and the overall cost dropped by nearly 15%.

(2 ) Optimize the combination of power supply components

The original power module used a dual regulator solution. Through power supply analysis, we merged it into a single-chip DC-DC solution, reduced the number of materials, simplified the SMT mounting process, and further saved labor and mounting costs.

(3 ) Unified packaging and centralized procurement of components

The dispersed resistors and capacitors of multiple 0201 packages were unified into the standard specifications of 0402 packages, and domestic brands with stable supply were selected to reduce redundant design and the frequency of material replacement of the mounting machine, improve loading efficiency and reduce error rate.

For conventional passive components (such as chip capacitors, resistors, TVS, and magnetic beads), we recommend that customers use domestic brands or public specifications. While not affecting performance, it significantly reduces the purchase price and delivery risk.

3. Streamlining SMT and DIP Manufacturing Processes

The PCB manufacturing assembly production process is not only related to the yield rate, but also affects the manufacturing unit price of each circuit board. In the customer’s circuit board manufacturing process, we found that many steps in the original process can be further compressed or optimized.

(1) SMT automatic placement machine

The customer’s original design contains multiple special-shaped components, such as high-pin USB sockets, manually mounted DIP buttons, and complex soldering inductor coils. These components not only affect the efficiency of placement, but also increase the cost of manual plug-in and wave soldering processes. Through structural integration, we use the surface mount technology process to replace some DIP plug-in components, increase the proportion of full automation, and significantly reduce the number of manual intervention points

(2) Optimize component layout and placement direction

Unnecessary double-sided SMT packages increase the placement process and placement machine occupancy time.

Adjust the position of components on the board so that more than 90% of the welding tasks can be completed by mounting on one side, reducing the number of board flips, and shortening the processing time of each circuit card assembly by an average of 12%.

(3) DFM inspection

Adjust the pad design and window ratio to improve the consistency of solder paste printing and avoid rework problems such as cold solder joints and bridges. This DFM (Design for Manufacturing) concept has increased the customer’s PCBA yield from the original 97% to 99.3%, saving not only money but also worry.

4. PCBA Cost Reduction ≠ Sacrificing Quality

Customer cases tell us that cost reduction and efficiency improvement in PCB fabrication and assembly is not simply reducing materials or suppressing the price of printed circuit board manufacturers, but:

Start with the optimization of printed circuit board design;

Use component replacement strategy to maintain performance unchanged.

Combined with standardized packaging + SMT patch process optimization to improve manufacturing efficiency.

5. SCSPCBA: A Trusted One-stop PCBA Manufacturing Service Expert

In the entire electronic product R&D and mass production chain, how to achieve high-efficiency, low-cost, high-quality PCB manufacturing and assembly has become the focus of more and more companies. SCSPCBA was born for this purpose. We are not only a circuit board manufacturer, but also a full-process collaborative partner for your product landing. As a trusted ceramic PCB manufacturer and PCBA supplier, SCSPCBA provides a one-stop turnkey PCB assembly service, covering PCB proofing, circuit design, PCB board fabrication, DFM manufacturability inspection, electronic board assembly, surface mount PCB assembly, BGA assembly, firmware burning, functional testing, full turnkey assembly, box build assembly, and packaging delivery. Our expertise also extends to automotive PCB assembly, industrial PCB manufacturing process optimization, and advanced assembly PCB projects for complex electronics.

Our engineering team has extensive experience in circuit board design and production, and is good at assisting customers in design optimization and cost reduction and efficiency improvement, reducing manufacturing costs and improving product reliability from the source. At the same time, SCSPCBA has advanced SMT production lines and BGA mounting processes, which can support mass production of simple single-sided boards to high-layer complex circuit boards, and is particularly good at customized services for medium-volume, complex-function electronic products.

In addition, we are equipped with a 24-hour online intelligent quotation system. You only need to upload the Gerber file and BOM list to quickly obtain a complete PCBA manufacturing quotation and delivery estimate, saving valuable time for product development. We always adhere to the concept of “customer first, quality first”, and assist many customers in the fields of smart home, industrial control, medical equipment, automotive electronics, etc. to quickly implement mass production and win market opportunities.

Choosing SCSPCBA means choosing a truly reliable manufacturing partner. Whether you are a startup team or a mature brand, contact us now for a free BOM quote. Our full turnkey PCB assembly service — from design to final box build — ensures you receive reliable, cost-effective solutions for industries ranging from automotive electronics to industrial control, medical devices, and consumer electronics.