Efficient smart manufacturing starts with “sticking”

In the modern electronic manufacturing industry, surface mounting technology ( SMT )has become an important circuit board assembly method and is widely used in smartphones, medical equipment, automotive electronics, industrial control, and other fields.

1. SMT Production Line: A Symphony of Intelligence and Efficiency

SMT production line consists of multiple key circuit board manufacturing process sections, each of which is crucial to the quality of the final product:

(1 ) Solder Paste Printer

(2) SPI Inspection

(3) High-speed/Multi-function Placement Machine

(4 ) Reflow Oven

(5 ) AOI Automatic Optical Inspection

(6 ) X-RAY Solder Joint Inspection

2. Solder Paste Storage Cabinet: Quality Control

As a key material in SMT surface mount technology, solder paste is extremely sensitive to temperature and humidity. The PEMS Intelligent Solder Paste Cabinet provides a constant temperature and humidity environment to ensure that the solder paste is stored in an ideal state to avoid oxidation or decreased activity.

3. SMT Quality Control

In the SMT production process, the quality management system plays a vital role, which is directly related to the yield and reliability of the circuit board. In order to ensure the welding quality and mounting accuracy, printed circuit board manufacturers generally introduce multi-level detection methods.

( 1 ) SPI Detection

SPI (Solder Paste Detection), located after the printing process, detects key parameters such as solder paste thickness, height, and area, which can effectively prevent defects such as insufficient solder, solder bridges, and cold solder joints, laying a good foundation for subsequent surface mounting links.

( 2 ) AOI Automatic Optical Inspection

AOI automatic optical inspection is performed after patching and reflow soldering. It uses high-definition cameras and image comparison technology to identify problems such as offset, reverse, missing, wrong and poor soldering. It has high accuracy and fast detection speed, which significantly improves the production efficiency and yield rate of board for circuit.

( 3 ) X-ray Detection

X-ray detection can see through the internal structure of solder joints and judge defects such as empty solder joints, solder ball offset, and missing pads. It is an indispensable detection method for high-end printed circuit board manufacturing.

(4 ) MES System Docking

Connect with the MES system to achieve full process data tracking from incoming materials to shipment. Each circuit board has its independent production history, including process parameters, test results, responsible persons and other information, to ensure that problems can be traced, quality can be controlled, and customers can rest assured.

SCSPCBA has the above set of strict quality control systems, which has built the trust foundation of SMT manufacturing and is the high reliability and consistency of printed circuit assembly.

4. SMT Online Quotation System: Get Accurate PCBA Prices

In the rapidly changing electronics manufacturing market, efficiency and transparency have become important criteria for customers to choose SMT suppliers. To this end, SCSPCBA circuit board manufacturers have developed an advanced online quotation system, dedicated to providing customers with fast, intelligent, accurate and transparent one-stop PCBA quotation services, greatly simplifying the procurement process and improving product launch speed.

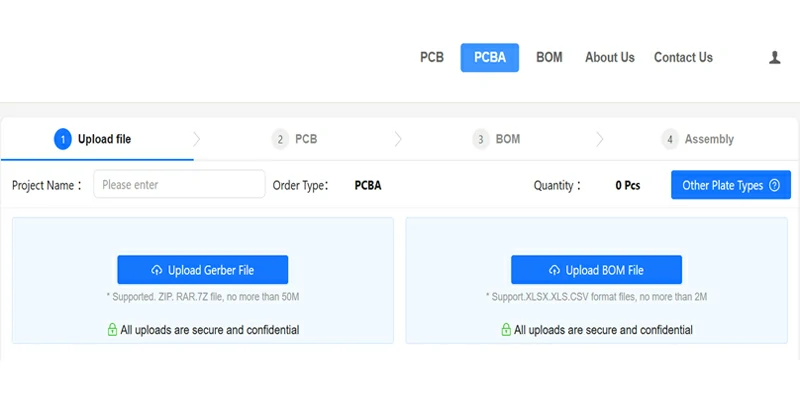

(1) Upload BOM & Gerber Files for Instant Analysis

Users only need to upload BOM and Gerber files, and the system can instantly analyze key information such as component model, package, usage and PCB board layer structure, and quickly estimate material costs. The system connects to multiple mainstream component supplier platforms, compares spot prices and batch inventory information in real time, and helps customers choose the most cost-effective device solution.

(2) AI Big Data Analysis

Through AI big data analysis, the system can also automatically recommend equivalent alternative components and select available solutions from a database of more than 10,000 products to further optimize the cost structure. In periods of component shortage or price fluctuations, multi-supplier price comparison and alternative suggestions are provided to keep customers in control.

(3) Full-process Quotation

The entire system can generate a full-process quotation including material procurement, PCB manufacturing, SMT patch, and functional testing within 10 seconds, and clearly list the details of each cost. The price is transparent and there is no hidden cost, which greatly enhances customer trust.

(4) Full-process Tracking

Customers can place orders with one click and track the entire process of production orders through the system, including key links such as material completeness, patch progress, test nodes, and delivery time, truly realizing a digital and visual project management experience.

5. Choosing A Professional SMT Manufacturer Means Choosing Stability and Efficiency

SCSPCBA PCB board manufacturers has created a closed loop of intelligent manufacturing that integrates component procurement, PCB manufacturing, SMT assembly, functional testing, and finished product assembly, thereby achieving:

- Reducing procurement and management costs

- Speeding up delivery cycles

- Improving product consistency and traceability

- Expanding flexible production capabilities for multiple varieties and small batches

Whether it is a start-up technology company or an international brand, choosing an experienced, advanced equipment, and a sound quality system SMT supplier is a key step in the successful launch of a product.

If you are looking for a trustworthy SMT partner, welcome to experience our 10-second intelligent quotation system, or visit our SMT smart factory to experience the charm of “efficiency + quality” in smart manufacturing.