Medical Printed Circuit Assembly Manufacturing

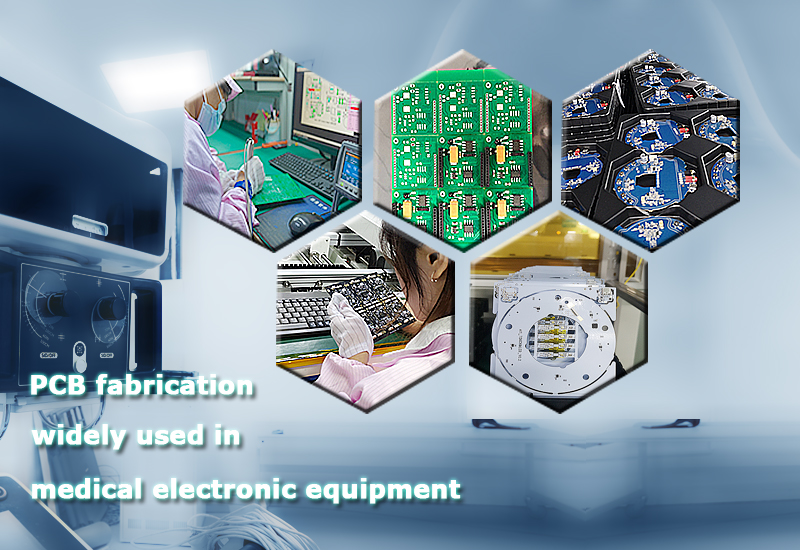

Printed circuit assemblies are widely used in medical electronic equipment, offering high precision, high stability, and miniaturization to meet the stringent requirements of the healthcare industry. Advanced medical-grade PCB manufacturing supports innovation in diagnostic, monitoring, and treatment devices such as electron microscopes, photometers, gas analyzers, cardiovascular stent detectors, ultrasound machines, photon therapy equipment, EKG and EEG machines, MRI, CT scanners, and blood pressure monitors. With continuous printed circuit assembly technology advancements, medical devices now provide faster and more accurate diagnostics, efficient treatment solutions, and reliable patient monitoring systems.

1. Medical PCB Board Fabrication Requirements

● Compliance with Medical Standards

Medical PCB design and manufacturing must meet strict industry regulations, including:

- ISO 13485 – Ensuring a robust quality management system for medical devices.

- IEC 60601 – Establishing safety and performance standards for medical electrical equipment.

- RoHS Directive – Restricting hazardous substances to enhance environmental safety.

Meeting these standards ensures high-reliability circuit card assembly solutions for life-critical applications.

● Durability and Longevity

Medical electronic devices must operate reliably for extended periods. The medical circuit board manufacturing process focuses on durability, incorporating high-temperature-resistant PCB materials, advanced soldering techniques, and protective coatings to enhance longevity.

● Safety Measures

To ensure patient and operator safety, medical device circuit boards incorporate:

- Optocouplers and transformers for electrical isolation between high-voltage and low-voltage circuits.

- Leakage current protection to prevent electric shock hazards.

- UL 94 V-0 flame-retardant materials to reduce fire risks.

● Component Selection for Medical Circuit Board

High-reliability medical-grade electronic components must be used to minimize failures. Flame-retardant PCB materials, low-noise capacitors, and ESD-protected ICs ensure stable device operation.

● Signal Integrity & Electromagnetic Compatibility (EMC)

To prevent signal distortion in medical environments, EMC-compliant PCB board design using:

- Shielding techniques for noise reduction.

- Optimized PCB layout to reduce electromagnetic interference.

- Controlled impedance PCB traces for high-speed signal transmission.

● Testing and Quality Assurance

Every medical circuit board undergoes rigorous testing to ensure safety and performance, including:

- Functional testing to verify circuit integrity.

- Environmental stress testing under varying humidity, temperature, and vibration conditions.

- Reliability testing to ensure long-term operational stability.

2. Common Medical PCB Applications

● Medical Monitoring Devices

Printed circuit manufacturing and display real-time patient data for:

- ECG monitors

- Blood oximeters

- Blood pressure and heart rate monitors

● Medical Imaging Equipment

PCB manufacturing and assembly manage sensors and signal processing for:

- Ultrasound machines

- MRI and CT scanners

- X-ray imaging systems

● Medical Treatment Equipment

PCB fab and assembly control and monitor operational parameters in:

- Dialysis machines

- Infusion pumps

- Laser surgery systems

● Laboratory and Diagnostic Devices

Medical PCB fabrication and assembly facilitate sample processing and data analysis in:

- Automated blood analyzers

- Endoscopes

- Dynamic electrocardiogram monitors

● Implantable and Wearable Medical Devices

Miniaturized flexible PCBs (FPCs) and rigid-flex PCBs enable:

- Pacemakers

- Insulin pumps

- Neurostimulators

● Advanced Remote Patient Monitoring

Wireless IoT-enabled medical PCBs support:

- Wearable health-tracking devices

- Remote patient monitoring systems

- Mobile health applications

3. Medical PCB Board assembly Technology & Innovations

The latest medical printed circuit assembly drives the miniaturization, intelligence, and networking of medical electronics. Cutting-edge high-density interconnect (HDI) PCB technology, multilayer PCB fabrication, and advanced surface-mount technology (SMT PCB assembly) provide:

- Higher circuit density for compact medical devices.

- Faster data transmission for real-time monitoring.

- Reliability in life-critical applications such as pacemakers and defibrillators.

Future Trends in Medical PCB Manufacturing

- Miniaturized PCBs for Wearable Health Tech – Enables continuous health monitoring with lightweight, flexible circuits.

- AI-Integrated Medical PCB Solutions – Enhances diagnostics and predictive analytics.

- Biocompatible and Flexible Circuit Board – Expands applications in implantable medical devices.

- Advanced Printed Circuit Board Testing for Medical Compliance – Ensures superior safety and performance in evolving healthcare environments.