Smart Component Sourcing Reduces PCBA Cost and Strengthens Your Supply Chain

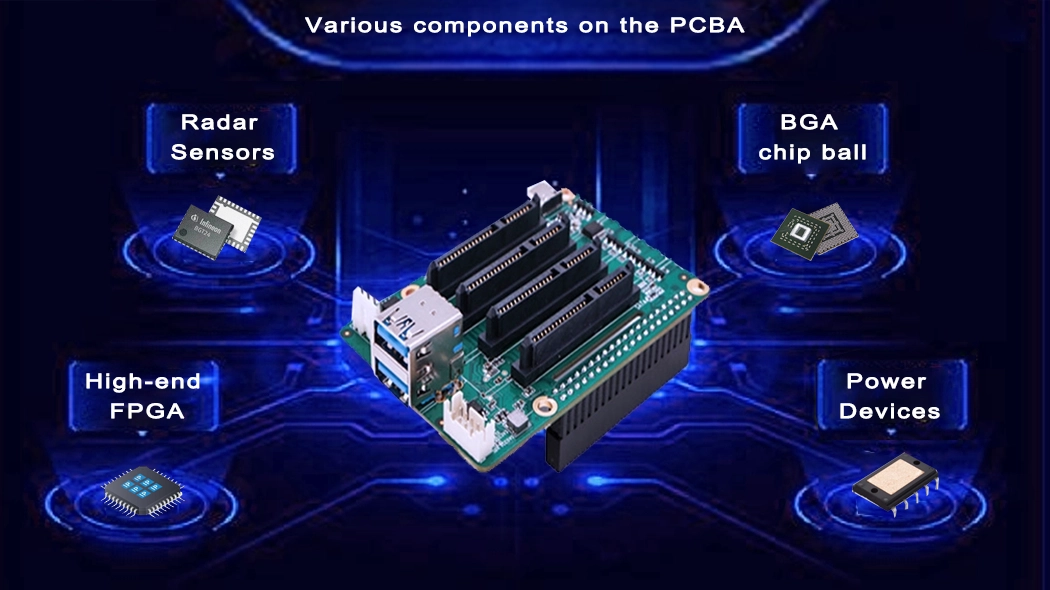

The development of circuit board manufacturing relies on supply chain stability and cost-effective component sourcing. For OEM/ODM companies, PCBA prices no longer depend solely on SMT assembly processes or production capacity; the most critical factors are the availability, authenticity, and strategic selection of electronic components.

With increasing prevalence of component shortages, price fluctuations, and long lead times, optimizing bills of materials (BOMs) and procurement strategies is crucial for reducing costs and improving the PCB board manufacturing process.

1. Reasons Why Component Procurement Determines PCBA Cost

Over 70% of the total PCBA cost depends on electronic parts, not manufacturing. A long lead time can delay your entire project by weeks. A counterfeit module can lead to product recalls or field failures. An obsolete component can force you to redesign the entire circuit board.

Therefore, OEM/ODM buyers are increasingly focusing on the BOM and supply chain strength of PCBA manufacturers, not just their SMT (Surface Mount Technology) capabilities.

(1) PCBA Cost

- Circuit Board Component Price Fluctuations

- Key components (such as chips and sensors) are significantly affected by supply and demand. For example, a global semiconductor shortage can cause prices to soar, directly increasing BOM (Bill of Materials) costs.

- Alternative Selection: High-performance, cost-effective components require a trade-off between performance and cost. For example, choosing domestically produced alternative chips may reduce costs by 30%, but reliability needs to be verified.

- Purchasing Scale and Supply Chain Negotiation Power

- Bulk purchases usually enjoy discounts, but small-batch customized products may face premiums. For example, the unit price of ordering 100,000 resistors may be 50% lower than that of 1,000.

- Hidden Costs

- Logistics costs (e.g., air freight for urgent orders is 3-5 times more expensive than sea freight), tariffs (different tax rates for different origins), and inventory management costs (loss of obsolete materials) must all be included in the total cost accounting.

(2) Delivery Time

- PCB Board Component delivery time differences

- Standard resistor/capacitor delivery time is typically 2-4 weeks, while high-end FPGAs or MCUs may require more than 12 weeks.

- The verification period for alternative solutions during stockouts (e.g., redesigning PCBs to adapt to new components) may delay projects by 1-2 months.

- Supply Chain Resilience

- Single Supplier Risk: If relying on a specific manufacturer (e.g., TI or ST), sudden production stoppages (e.g., fires) will lead to supply chain disruptions. A multi-source supply strategy can mitigate this risk.

(3) Finished Product Assembly

- Performance and Reliability

- Low-priced components may sacrifice yield or lifespan. For example, the use of low-end capacitors in consumer electronics has led to a 15% increase in return rates and damage to brand reputation.

- Key electronic circuit board components (e.g., industrial-grade chips) must be certified (AEC-Q100), otherwise, field failures may occur.

- Technological Innovation and Competitiveness

- Cutting-edge devices (such as GaN power devices) can improve energy efficiency, but are difficult to procure; delayed procurement may lead to outdated product technology.

- Compliance and Sustainability

-

- Environmental regulations (such as RoHS and REACH) require devices to be free of hazardous substances; non-compliant procurement will face fines or recall risks.

2. BOM Optimization and Alternative Component Strategies to Reduce PCBA Costs

BOM optimization and component substitution strategies are the core of printed circuit manufacturing cost reduction. Component substitution strategies, through methods such as specification matching and domestic substitution, can achieve a 10%-30% reduction in single-device cost.

(1) Precise Specification Matching

- Avoid “performance overkill,” such as replacing ordinary indicator lights with commercial LEDs, which reduces indicator light circuit component costs by 60% and single-device costs by 30%-50%.

- Focus on components with the largest share of bill of materials cost:

- Microcontrollers

- Power Management ICs

- Wireless SoCs

- High-volume use of thick-film resistors

- Connectors and shielding components

(2) Domestic Substitution

- Prioritize certified domestic printed circuit board components alternatives and establish a cost-reduction BOM (Bill of Materials) database.

- For example, if an industrial control customer domesticates 10 components, the cost per board will decrease by 12.8%, and the overall cost will decrease by 8%-15%.

- Replace specific brand printed components with domestically produced components of the same function.

(3) Standardized Packaging

- Using standard packages such as 0402/0603 reduces the need for special pcb board fabrication processes.

-

- Replacing irregularly shaped capacitors with standard packages reduces fixture costs by 50%. Production efficiency increases by 15%, and loss rate decreases by 2%.

3. BOM Full-Process Optimization

As the core link between circuit design and PCB board fabrication, the optimization of the BOM needs to be carried out throughout the printed circuit board production process.

(1) PCB Design Phase

- Unified Data Source

Using a single BOM as the standard, clearly define the PCB board manufacturing process and circuit board manufacturing to avoid inconsistent data from multiple departments. - Standardized Coding and Structure

Establish unique material coding rules with clear hierarchical divisions to prevent multiple codes for the same item. - DFM Collaborative Design

Combine design for manufacturability (DFM) principles to eliminate redundant PCB board parts. For example, prioritize the use of standard packaged components (0603/0402 resistors and capacitors) to reduce special material requirements.

(2) Procurement and Materials Management Phase

- Material Consolidation

Consolidate materials with similar specifications. For example, unify five types of resistors into one standard value. This reduces SKUs, improves purchasing power, and lowers warehousing costs. - Alternative Material Management

Collaborate with suppliers to build an alternative material pool. Label 1-2 compatible models for key components, such as BGA chips. This mitigates stockout risks and shortens lead times. - Lifecycle Management

Avoid discontinued (EOL) components and prioritize components with long lifecycles. This reduces modification costs and ensures supply chain stability.

(3) PCB Board Production Phase

- System Integration

Automatically synchronize BOM data to the production process, driving the generation of procurement plans and production orders, reducing manual data entry errors - Dynamic Adjustment

- Dynamically adjust material requirements by merging similar orders within the system.

- Set differentiated loss rates based on material characteristics (e.g., 0.3% for surface mount resistors and capacitors, 1.5% for QFP chips) to avoid over-purchasing.

- Utilize a BOM lifecycle management system to prevent outdated BOMs from entering the SMT production line by binding material batches and versions.

4. How SCSPCBA Reduces Component Procurement Costs

SCSPCBA boasts a professional component procurement team and extensive supplier partnerships in Shenzhen, Hong Kong, and other locations. Unlike factories that only provide assembly services, SCSPCBA’s procurement process is designed to ensure quality, reduce costs, and achieve global traceability.

Our procurement advantages include:

(1)Direct Procurement from Authorized Distributors

This eliminates the risk of counterfeit products and ensures batch traceability.

(2)Multi-Regional Price Comparison to Reduce Costs

- Distributor Spot Market Prices

- Regional Inventory

- Delivery Cycle Fluctuations

- Cross-Brand Alternatives

- Historical Price Trends

- This allows us to lock in the lowest global prices for high-volume printed circuit board assembly

(3)Internal IQC Quality Inspection and Traceability

All components undergo the following inspections:

- Solderability Testing

- Label and Batch Number Verification

- Microscopic Inspection

Ensuring that every printed circuit board part is 100% original and of reliable quality.

(4)High-Reliability Component Services

We provide the following services to customers in the automotive, IoT, industrial control, medical electronics, and consumer electronics industries:

- Average PCB material savings: 12-22%

- Leadership reduction: 1-3 weeks

- Production yield improvement: 1.5-3%

5. SCSPCBA Smart BOM Quote

To further simplify the PCBA component sourcing process and accelerate cost optimization, SCSPCBA has independently developed a Smart BOM Quote tool, significantly improving quoting efficiency, accuracy, and transparency. Through this system, customers only need to upload their BOM file (Excel/CSV/Gerber annotation), and the system automatically analyzes each component, including its historical purchase price, certified supplier inventory, alternative original parts options, regional lead times, and risk level.

The Smart BOM Quote offers the following key advantages:

- Fast Response

Typically provides an initial BOM quote within minutes, saving 50–80% of time compared to traditional manual inquiries. - Cost Transparency

Clearly displays the source, price range, and alternatives for each component, allowing customers to intuitively assess BOM cost reduction potential. - Risk Control

The system automatically identifies components with long lead times, high price volatility recommends reliable alternatives, reducing supply chain risk. - Collaborative Optimization

Customers and SCSPCBA engineers can collaboratively adjust the BOM online, optimizing the design through version comparison to ultimately achieve the best cost-performance solution. - Traceability

All quotation history, selection decisions, and component changes are recorded, facilitating subsequent review and quality tracking.

Through its intelligent BOM quotation tool, SCSPCBA not only helps OEM/ODM customers significantly reduce material costs but also ensures genuine products, stable delivery times, and flexible supply in the procurement process. This innovation transforms optimized component sourcing from a tedious process of manual, repetitive price negotiations into a standardized, data-driven, predictable, and highly collaborative end-to-end solution.

6. How SCSPCBA Helped a Customer Reduce Bill of Materials Costs by 27% in 3 Weeks

In-depth Analysis of a Turkish Consumer Electronics Customer’s 27% Bill of Materials Cost Reduction in 3 Weeks

A Turkish consumer electronics company planned to launch a new generation of smart home devices, facing three major pressures:

- Delivery cycle crisis: The original global supply chain required 14-18 weeks, causing product launch delays;

- Soaring costs: Prices of core printed circuit board parts (such as MCUs and power management chips) increased by 32% year-on-year, exceeding the budget for BOM costs;

- Urgent launch: Competitors had released their products 3 months ahead of schedule, requiring mass production to be completed within 6 weeks.

As a result, SCSPCBA helped a customer reduce BOM costs by 27% within three weeks using its self-developed BOM quote system.

SCSPCBA PCB Assembly Company’s Emergency Response

SCSPCBA analyzes every item in customer-submitted BOM documents using its proprietary intelligent BOM quotation system. Combined with its data model containing over 100,000 components, the system quickly identifies cost anomalies, alternative component solutions, and supply chain risks, thereby initiating efficient electronic supply chain optimization.

(1)Reduce BOM costs by 27% through intelligent BOM analysis and precise alternative solutions

The Role of the Intelligent BOM System

- SCSPCBA’s intelligent BOM system automatically identified four high-cost ICs with redundant functions in the customer’s BOM.

- For example: A certain MCU integrates a Bluetooth module, while the customer only needs basic I/O control functions.

Optimizing Component Procurement Strategy

- The system automatically matched three domestic alternative models based on performance models.

- The recommended alternative models are fully compatible in terms of pin package, operating voltage, clock frequency, and temperature range.

- Engineers and the purchasing department jointly verified these alternative models, completing the evaluation in just 3 days.

Final Results

- 40% Reduction in Domestic IC Costs

- Ultimately, the overall BOM cost was reduced by 27% (from solution submission to confirmation, a total of 3 weeks).

(2) Lead Time Shortened from 10 Weeks to 6 Weeks

Smart BOM Helped

- The system automatically retrieves global supplier inventory, prioritizing matching with readily available stock in nearby warehouses.

- Supports “automatic splitting of urgent demands” logic, initiating a 72-hour fast delivery mode.

Supplier Collaboration

- Risk-sharing agreements are signed with core component manufacturers.

- Suppliers are responsible for holding safety stock, and customers take delivery in batches as needed.

- Costs remain unchanged, but delivery time is significantly shortened.

(3) 100% Original Parts Traceability

Blockchain Traceability System

- Each circuit board component generates a unique digital ID, recording information such as production batch, quality inspection report, and logistics trajectory.

Batch Certificates

- The system generates batch certificates compliant with ISO 9001 standards, reducing manual review time.

Customer Visibility

- Customers can query the origin of components in real time through the platform, enhancing trust.

(4) Zero Design Changes

Alternative Selection Criteria

- The number and arrangement of pins are completely consistent with the original; The operating voltage, current, temperature range and other parameters match;

3-Day Technical Verification

SCSPCBA assembles a rapid assessment team, including:

- Component Engineers

- Purchasing Engineers

- Customer R&D Engineers

Together, they complete all compatibility and functional verifications within 3 days, ensuring no hardware or software modifications are required.

SCSPCBA’s Intelligent Supply Chain System Collaborates with the Engineering Team:

- Intelligent BOM tool analyzes data from 100,000+ components

- Daily progress synchronization across SMT, Procurement, and Logistics departments

- Local supplier priority supply agreements ensure sustainable supply

Ultimately achieving the triple goals of cost reduction, shorter lead times, and reduced risk

SCSPCBA not only provides PCB assembly and manufacturing but also helps companies achieve cost reduction, speed improvement, and compliance assurance in their supply chain through its self-developed intelligent BOM service, thereby building stronger global manufacturing competitiveness.

6. A More Robust BOM and Supply Chain

In today’s competitive electronics market, optimizing PCB board component sourcing and BOM strategies has a direct impact on product cost, reliability, and delivery speed. Whether you’re an OEM scaling up production or an ODM launching new designs, the right PCB manufacturing and assembly partner can help you mitigate risk, reduce costs, and stabilize your supply chain in the long term.

With SCSPCBA’s global sourcing network, engineering expertise, and original equipment manufacturer (OEM) component guarantees, your projects will benefit from a more reliable, cost-effective, and future-proof supply chain.

Take Action Now →