PCBA in EMS/OEM/ODM Smart Manufacturing Solutions

1. PCBA is the Core of EMS, OEM & ODM Manufacturing

In the modern electronics manufacturing supply chain, EMS (Electronic Manufacturing Services), OEM (Original Equipment Manufacturer), and ODM (Original Design Manufacturer) constitute the mainstream foundry models. Although their roles differ, they all rely on a common core process—PCB manufacturing and assembly. Whether the brand owner leads the design or the foundry participates in the entire development process, the stability of the final product’s performance and the completeness of its functions almost entirely depend on the quality and reliability of the PCBA manufacturing.

In automotive ADAS, power management, medical monitoring equipment, smart home systems, and industrial control systems, high-precision PCB design, SMT assembly, BOM supply chain management, and functional testing such as ICT, FCT, and X-ray are all essential.

However, traditional PCBA suppliers often face the following challenges:

- Increased requirements from major brands

Major brands have stringent requirements for PCB board makers’ industry standards, production technologies, testing technologies, and management processes. Suppliers need to undergo multiple rounds of rectification and stable supply before becoming a consistently chosen PCBA supplier. - Production technology

Circuit boards are evolving towards precision, miniaturization, shortening, thinning, and lightness, increasing the technical processing requirements for PCB assembly companies. - Rising production costs

Rising PCB and component prices put greater pressure on contract manufacturers with incomplete supply chains. Furthermore, production processes, staffing, and equipment maintenance need to be optimized to reduce costs. - Production efficiency and technological challenges

With the diversification of electronic products and rapidly changing market demands, traditional processing methods struggle to meet rapid delivery requirements. Material selection and management, quality control, and rapidly changing customer needs also present challenges. - Environmental pressure

With increasing environmental awareness, printed circuit board assembly companies need to adopt more environmentally friendly measures in their production processes, such as choosing lead-free soldering materials and environmentally friendly cleaning agents, and paying close attention to waste disposal.

SCSPCBA’s advantages: We are not a traditional factory, but a modern EMS manufacturing platform driven by “intelligence + visualization + AI”.

2. EMS/OEM/ODM

Printed Circuit Board Assembly refers to a circuit board assembly on which electronic components (such as resistors, capacitors, and chips) have been mounted on a bare board using SMT or DIP processes. It is the “brain” of all electronic devices; whether it’s a mobile phone, home appliance, or industrial controller, all rely on the PCBA to realize their functions.

(1) EMS (Electronics Manufacturing Services)

In EMS, customers require stable mass-production capabilities and quality control; the PCBA is the object of processing; and the EMS manufacturer is an “all-around contract manufacturer,” responsible for turning the customer’s drawings into physical products.

SCSPCBA focuses on circuit board assembly services:

- Offering a one-stop manufacturing capability encompassing component procurement, SMT/DIP mounting, functional testing, and complete system assembly.

- Full-process contract manufacturing (SMT, BGA, testing, assembly)

- Automated reflow soldering + SPI + AOI + X-Ray

- ICT, FCT, burn-in testing

- Complete traceability system (barcode + workstation data)

For example, in industrial control board electronics, customers only need to provide the Bill of Materials (BOM) and Gerber files; SCSPCBA provides a full-process EMS service including PCB board fabrication, PCB assembly, testing and inspection, molding, and final assembly.

(2)OEM (Original Equipment Manufacturer)

Among OEMs, the printed circuit board assembly manufacturer only performs conversion and does not change the design.

SCSPCBA offers

- DFM (Design for Manufacturability)

- DFA (Design for Assembly)

- BOM cost and substitute material analysis

- Multi-factory simultaneous production (Shenzhen + Jiangsu + Jiangxi + Vietnam)

(3)ODM (Original Design Manufacturer)

In ODM, printed circuit board assembly companies not only produce, but also provide complete solutions. For example, scspabc provides customized PCBA for AI hardware customers to support the rapid creation of smart products.

SCSPCBA offers

- Scheme design

- PCB Layout

- Proofing + small batch verification

- PCBA + housing + packaging + functional testing

3. Differences in PCBA production between OEM and ODM

(1)Comparison of specific differences

| OEM mode | ODM mode | |

|---|---|---|

| Design Ownership | The brand provides complete design (including circuit diagram, BOM table, etc.) | The factory is responsible for the entire process design from product definition to mass production. |

| PCB assembly manufacturer responsibilities | The manufacturer constructs according to the drawings, focusing on processes such as SMT patching, DIP plug-ins, and testing. | Provide one-stop service of “design + R&D + production + certification” |

| Intellectual property ownership | All technical achievements belong to the brand owner | Design copyright usually belongs to the factory, and customers can buy it out or share it |

| Cost and cycle | The cost is low, but the brand needs to invest a lot of R&D resources; the market cycle is long | Can save R&D time and cost, suitable for rapid market introduction |

| Applicable business types | A mature brand owner with a strong R&D team and clear product planning | Start-ups or brands that lack hardware capabilities want to travel lightly |

(2)Select suggestions

OEM emphasizes “manufacturing execution” and the brand leads the design

ODM provides “system output”. Complete solution provided by printed circuit board assembly factory

- If you already have a mature design solution and value brand independence and technical confidentiality, you should choose OEM.

- If you only have preliminary ideas and are pursuing rapid implementation and cost control, ODM is more suitable.

- In actual business, many companies adopt a mixed strategy: initially using ODM to verify the market, and later switching to OEM independent design to master core technologies.

4. SCSPCBA’s Core Differentiation in EMS, OEM & ODM Manufacturing

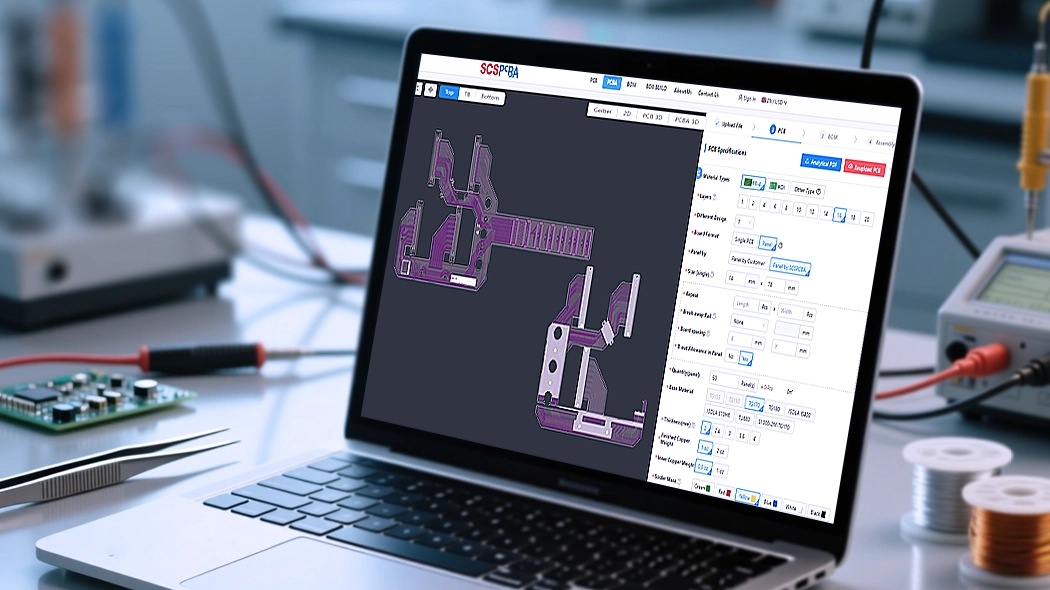

(1) AI Smart Quotation System Covering PCB, PCBA, BOM & Box Build

Unlike traditional EMS suppliers that rely heavily on manual quoting and fragmented spreadsheets, SCSPCBA has developed an AI-driven quotation system designed specifically for PCB and PCBA manufacturing scenarios.

Our intelligent quoting platform supports:

- PCB fabrication (layer count, material, stack-up, impedance, surface finish)

- PCBA assembly (SMT, DIP mixed technology, testing requirements)

- BOM analysis & sourcing (component availability, lifecycle status, alternative parts)

- Box build assembly (mechanical parts, wiring, functional test cost modeling)

By automatically parsing Gerber files, BOM lists, and manufacturing parameters, the system calculates material cost, process complexity, yield impact, and production capacity in real time.

Key advantages:

- Quotation generated, compared to 24–72 hours in traditional EMS workflows

- Cost structure transparency allows OEM and ODM customers to evaluate trade-offs early

- ±5% pricing deviation, significantly lower than industry average

(2)Advanced Manufacturing Base

SCSPCBA operates four advanced manufacturing sites, forming a strategically distributed production network that supports flexibility, scalability, and supply-chain resilience.

Manufacturing footprint:

- China PCBA Factory – Shenzhen

Focused on high-mix, high-complexity PCBA, rapid prototyping - China PCB Factory I – Jiangsu

Specializing in multilayer, HDI, and high-reliability PCB fabrication - China PCB Factory II – Jiangxi

Optimized for cost-effective medium-to-high volume PCB production - Vietnam PCBA Factory

Supporting export-oriented PCBA manufacturing with competitive labor成本 and tariff advantages

Each site is equipped with:

- Fully automated SMT line

- SPI, AOI, X-ray inspection

- MES-based production monitoring

- Unified quality and process standards

This multi-location structure enables SCSPCBA to balance cost, lead time, and capacity, making it particularly suitable for global EMS 、ODM and OEM programs that require stable long-term supply.

(3)Strong Supply Chain & Component Sourcing Capability

Component procurement is often the biggest risk factor in PCBA projects, especially under global supply volatility.

SCSPCBA addresses this challenge with a dedicated, experienced sourcing team and a data-driven procurement strategy.

Our supply chain advantages include

- Direct cooperation with authorized distributors and OEM channels

- Long-term relationships with component brands (power, passive, connectors)

- Alternative component validation supported by engineering teams

What this means for customers:

- Stable lead times even during component shortages

- Lower total BOM cost without sacrificing reliability

- Reduced risk of counterfeit or grey-market parts

- Faster response for EMS customers with urgent replenishment needs

(4)End-to-End PCBA Manufacturing (From PCB to Box Build)

SCSPCBA delivers true end-to-end PCBA services, rather than fragmented outsourcing across multiple vendors.

Our integrated workflow includes:

- PCB fabrication

- SMT & DIP assembly

- Mixed-technology PCBA

- ICT, FCT, aging and reliability testing

- Box build and final product assembly

For EMS/OEM customers, this reduces coordination cost and risk.

For ODM customers, it accelerates time-to-market and ensures design intent is preserved through manufacturing.

(5)Certification Quality System

SCSPCBA’s quality system covers every aspect from component warehousing to finished product packaging. We strictly follow industry standards such as ISO9001, ISO14001, ISO13485, IATF16949, etc. to ensure that it is suitable for high-reliability applications such as automotive, medical, and communications.

Quality inspection links include:

- SPI solder paste inspection

- Online AOI automatic optical inspection

- X-Ray (BGA, QFN soldering verification)

- ICT Hardware Circuit Bed of Needles Testing

- FCT functional test (can be customized according to customer plan)

- 72–120 hours burn-in test (on demand)

Each PCBA has a unique SN traceability code, which can be traced through the MES system:

- Conponent batch

- production station

- Test records

- Test curve

- QA approver

This allows our PCBAs to maintain a rework rate of <0.12% in the fields of automotive electronics, medical electronics and industrial electronics, well below the industry average.

5. Service Advantages

(1) PCB Manufacturing

- Single Layer PCB

- Double Layer PCB

- Multilayer PCB

- Ultra-High-Layer PCB

- HD PCB

- Rigid-Flex PCB

- High-frequency PCB

- Aluminum PCB

- Ceramic PCB

- Thick Copper PCB

- High-Tg PCB

- Flexible PCB

(2)SMT Assembly

- SMT Process Flow:

- Solder Paste Printing

- SPI (Solder Paste Inspection)

- High-speed Component Placement

- Reflow Soldering

- AOI (Automated Optical Inspection)

- X-ray Inspection (for BGA/QFN packages)

(3)PCBA Assembly

- DIP/Wave soldering

- Three-proof paint, glue filling, and complete machine testing

- OEM/ODM finished product assembly

6. FAQ

(1)What is the difference between EMS, OEM and ODM?

EMS focuses on manufacturing, OEM is responsible for producing branded products, and ODM provides the entire process from design to production.

(2)Do you support automotive or medical-grade production?

Support: the factory has IATF 16949 and ISO 13485 certifications.

(3)Can SCSPCBA provide an alternative component suggestion?

Yes, we provide BOM cost optimization and substitute material recommendations (including inventory cycle and life cycle analysis).

(4)What file formats do you support?

Supports PCB archive files (zip, .rar, .7z), KiCad 6.0+ files (kicad pcb), AD16+ files (.PcbDoc), no more than 50M

(5)Do you offer functional testing for PCBA?

Provide ICT, FCT, burn-in testing and customer-defined testing processes.

(6) Do you provide turnkey PCB + PCBA service?

Yes, including PCB → Components → SMT → DIP → Assembly → Testing

Ready to Start Your EMS/OEM/ODM PCBA Project?

Get an instant quotation in seconds and upload your Gerber/BOM files now.

[Get Instant Quote — Upload Files]