Premium PCB, Circuit Board & PCBA Services Tailored for Turkey’s Electronics Industry

1. Why choose Türkiye for PCB and PCBA manufacturing?

(1)Geographical and Trade Hub Status

- Spanning Eurasia, Turkey is a natural logistics center connecting Europe, the Middle East, and North Africa. For PCB and PCBA manufacturers, this means easier access to a broad customer base, including high-tech industries in Europe, electronics manufacturing hubs in Asia, and emerging markets in the Middle East. This geographical advantage helps reduce logistics time and costs, improving supply chain efficiency.

- As a member of the EU Customs Union, products entering the EU market enjoy tariff preferences, reducing trade barriers.

(2)Government Incentives and Industrial Transformation

- Turkey launched a $5 billion semiconductor incentive program to promote domestic chip design and production, driving the development of the upstream and downstream electronics industry chain.

- Government support encourages foreign companies to set up factories in new energy, smart manufacturing, and other fields, creating significant demand for circuit design, PCB assembly, PCB board fabrication, and high-reliability circuit board manufacturing.

(3)Labor Market

- Turkey has a relatively young workforce, providing ample labor resources for the manufacturing sector. For technology-intensive industries like PCB manufacturing and PCB assembly and manufacturing, maintaining high production efficiency is crucial.

(4)Market Demand Growth

- Domestic demand in Turkey continues to rise for smart home appliances, new energy equipment, and automotive electronics, driving the application of high-end circuit boards.

- The automotive industry is transitioning to new energy vehicles, and electric vehicles use more PCBs than traditional gasoline vehicles for electronic control systems, sensors, etc.

While Turkey is not currently a dominant force in global PCB/PCBA manufacturing, its geographical advantages, policy incentives, and market potential make it a highly attractive ideal location for Chinese manufacturers seeking to balance domestic and overseas markets in printed circuit board and printed circuit board assembly manufacturing.

2. Our Production Capabilities: Advanced Lines Built for Speed & Quality

(1) SMT Assembly Capability

Our high-speed SMT production line is equipped with advanced equipment, such as:

- Automatic board feeder

- Solder paste printer

- Solder paste inspection SPI

- Yamaha automatic high-speed pick-and-place machine (YSM20, YSM20R)

- AOI automatic optical inspection system

- Nitrogen reflow oven

- Dual-track board take-up machine

Supports high-precision component assembly, including:

- Minimum placement: 0201 & 01005

- BGA / QFN / CSP accuracy: 0.25mm–0.4mm pitch

- Daily placement capacity: 3.2M+ components/day (supports large-volume orders)

- Double-sided placement + reflow soldering technology, temperature profile monitoring throughout

Before each production run, we perform DFM (Manufacturability Analysis) on the documents to ensure that the PCB design, Gerber, and BOM are correct.

(2)AOI, SPI, X-Ray Full Inspection Process

To ensure the stability of every circuit board, we perform full-process inspection:

- SPI solder paste inspection to prevent solder bridging and insufficient solder

- 100% AOI inspection component misalignment, missing components, reverse orientation

- X-Ray inspection of BGA/QFN solder joints

- Automated optical measurement

Each process is supervised and verified by engineers to ensure compliance with international electronic assembly standards.

(3)Full Testing Capabilities

We offer professional testing services for automotive, industrial, and medical applications, including:

- ICT (In-Circuit Testing): Suitable for high-volume and high-reliability projects

- FCT (Functional Testing): Verifies the overall operational status of the device

- Aging Testing (24–72 hours): For consumer and automotive electronics

- High Voltage Testing, Insulation Testing, Temperature Cycling Testing, Reliability Testing

(4)End-to-End PCBA Manufacturing Workflow

We offer a complete end-to-end production process to reduce customer management costs:

- Online Gerber file upload

- DFM analysis and engineering review

- PCB manufacturing

- SMT + DIP + wave soldering/reflow soldering processes

- PCBA assembly

- PCBA testing and functional calibration

- Conformal coating

- Packaging and shipping

The entire process can be tracked in real-time via a digital dashboard, ensuring transparency and reliability.

(5)BOM & Supply Chain

Collaborating with the global electronic component supply chain for complete Bill of Materials (BOM) sourcing

We have established long-term partnerships with multiple authorized channels in the global electronics supply chain, ensuring:

- 100% Original Equipment Manufacturer (OME) electronic components

- Providing alternative components to reduce costs (when specific models are out of stock)

- Availability of automotive, industrial, and medical grade components

- Providing BOM cost optimization recommendations (potentially reducing procurement costs by 3%–12%)

3. Main Services We Provide for Turkey

(1) PCB Board Fabrication

We provide a full range of PCB manufacturing services for Turkish electronics manufacturers, from single-layer to multi-layer boards, meeting the needs of various industries including automotive electronics, industrial control, home appliances, power supplies, and communications.

- Capabilities

- 16-50 ultra-high-layer PCBs, HDI, thick-copper plates, impedance control, high TG PCBs, gold fingers, blind and buried vias, various surface treatments (ENIG, OSP, HASL, etc.).

- Advantages

- Strict IPC Class 2/Class 3 standards

- Automated exposure, AOI, flying probe testing, and mechanical and electrical testing throughout the entire process

- Rapid prototyping

This enables us to ensure stable, low defect rates and provide flexible capacity support for small to medium batch orders from Turkish customers.

(2) SMT Assembly

Our SMT production line provides high-speed, high-precision placement capabilities for the Turkey project.

- Equipment

- Yamaha high-speed placement machine

- SPI

- 3D AOI

- Nitrogen reflow soldering with full temperature control tracking

- Capabilities

- Minimum 01005 component placement

- High-reliability BGA/QFN/LGA soldering

- Double-sided placement and some manual soldering repair

- High-efficiency capacity of up to 450,000 CPH per SMT line

- Real-time tracking of material batches, solder paste profiles, and equipment status through the MES system to ensure production transparency and traceability.

(3)Complete PCBA Assembly

We provide Turkish clients with a complete solution from component sourcing to finished PCBA assembly:

- BOM optimization and alternative recommendations (cost reduction & ensure availability)

- Original authorized supply chain system (avoid counterfeit components)

- Customized testing processes such as ICT/FCT/programming/burn-in

- Wire harness, housing assembly, and box build assembly services

We can customize process flows based on the different product positioning of Turkish clients (mid-range, industrial-grade, automotive-grade) to ensure the final delivered PCBA meets the target application requirements.

(4) One-Stop PCBA Manufacturing Services

We have multiple smart factories in China and Vietnam, which can integrate all production processes into a single system:

- Circuit board manufacturing

- SMT Assembly

- DIP Component Insertion

- PCBA Assembly

- Testing

- Packaging and Logistics

This one-stop process reduces communication complexity, shortens lead times, and significantly reduces risks associated with cross-supply chain operations.

(5) Engineering Support

We provide comprehensive engineering support to our Turkish clients:

- DFM (Design for Manufacturing) on-site trial production summary report

- Welding curves, AOI statistics, defect rate analysis

- Continuous cost optimization support

With years of experience in PCBA manufacturing, we can provide our Turkish clients with clear and professional engineering judgments, improving product reliability and accelerating mass production success rates.

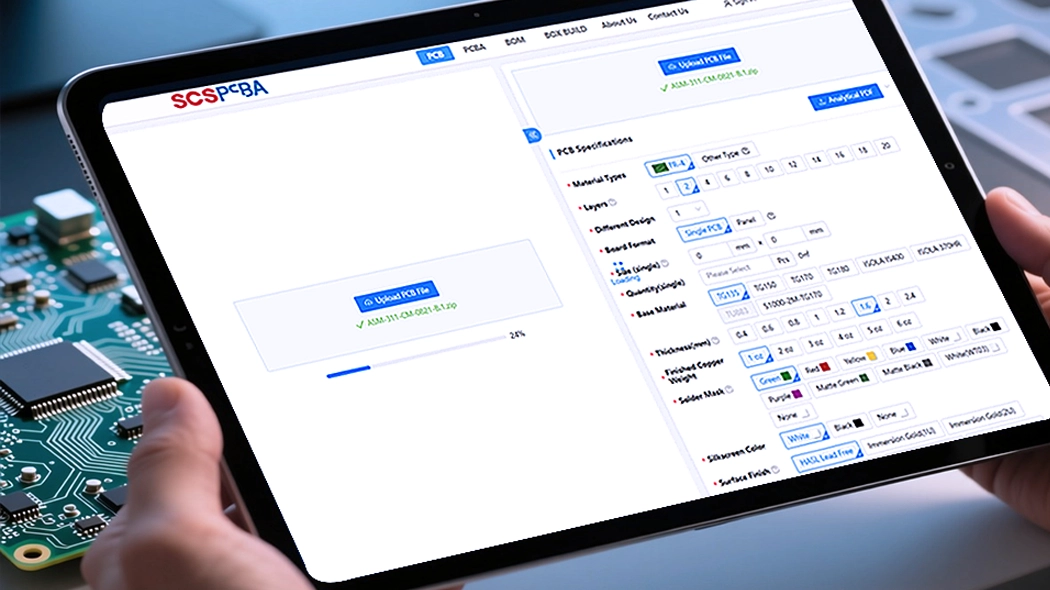

(6)PCB & PCBA Quotation Service

To help our Turkish clients quickly assess project costs and shorten product launch cycles, we offer fast, professional, and transparent PCB & PCBA quotation services. Our system not only supports standard quotations but also provides intelligent analysis based on common application needs in the Turkish electronics industry.

Real-time PCBA Quotation Platform

Our internal quotation system automates the following processes:

- Automatic BOM parsing

- Real-time matching of component supply chain inventory and prices to avoid material shortage risks

- Automatic generation of PCB costs based on parameters such as board thickness, number of layers, solder mask, copper thickness, and impact

- Predicting SMT process costs (number of placement points/difficulty/package) based on usage

- Automatic generation of total cost, alternative models

Engineering Review Before Quoting

To avoid hidden risks for our Turkish customers during mass production, we provide the following before issuing a formal quotation:

- Gerber engineering document review

- DFM (Manufacturability) assessment

- Component availability check

- Pad design and routing risk warning

- Cost optimization suggestions

For our Turkish customers, this means

- More accurate budget control

- Faster product initiation and solution evaluation

- Significantly reduced manual communication time

- Avoiding additional costs due to material shortages or delivery delays

4. Industry We Service

Our printed circuit board assembly manufacturing services serve multiple industries in Turkey, including consumer electronics, automotive electronics, industrial control, medical devices, and new energy.

(1) Consumer Electronics

Smartphones

Tablet PCs

Smart Home Devices

(2) Automotive Electronics

Vehicle Control Systems

Power Management Modules

Charging Stations

(3) Industrial Control

Robot Controllers

PLCs

Motor Drive Systems

(4) Medical Devices

Medical Instruments

Ventilators

Blood Pressure Monitors

Oxygen Concentrators

(5) New Energy and Energy Management

Solar Inverters

Energy Storage Systems

Lithium Battery Management

In R&D projects requiring rapid prototyping and small-to-medium batch production, we offer advantages in fast response and cost control. Our one-stop PCBA manufacturing utilizes two core assembly technologies: SMT (Surface Mount Technology) and DIP (Dual In-line Package) to adapt to different component types:

- SMT: Suitable for miniaturized, high-density components (such as chips and capacitors), commonly found in consumer electronics products such as smartphones and laptops.

- DIP: Used for through-hole components with leads (such as connectors and transformers), frequently found in industrial control boards and power modules.

5. Quality and Certification

Quality and reliability are at the heart of every circuit board we deliver to our Turkish customers. All our PCB manufacturing and assembly processes strictly adhere to international electronic manufacturing standards. Our factory is ISO9001, ISO13485 (medical electronics), and IATF16949 (automotive) certified.

Each circuit board undergoes a comprehensive testing process, including AOI, X-ray, ICT, FCT, high-voltage testing, and visual inspection by IPC-certified engineers. End-to-end traceability is achieved through an MES system, allowing for traceability of every PCB, every batch of components, and every production batch within seconds.

Whether you need high-layer HDI boards, precision circuit boards for circuit design, or complete PCBA assembly, our rigorous process control ensures stable performance, long service life, and low field failure rates.

6. FAQ

(1) Do you support small-lot PCB or prototype orders?

Yes, we support PCB prototypes and mass production.

(2) Can I upload files using our online quotation system?

Yes, you can use our built-in online quotation system to check your PCB design before placing an order.

(3) Do you provide electronics components sourcing?

Yes, we offer full BOM sourcing from authorized global suppliers.

(4)Can you handle automotive-grade PCBA?

Yes, we operate under IATF16949 quality control and support automotive testing.

(5)Can you ship directly to Turkey?

Yes, DHL/UPS/Aramex shipping arrives in 3–6 days.

(6)Do you provide full PCBA functional testing?

Yes, ICT, FCT, aging tests, HV tests are available.

(7)What PCB board fabrication technologies do you support?

HDI, impedance control, aluminum PCBs, Rogers, multilayer, blind/buried via.

7. Ready to Start Your PCB or PCBA Project for Turkey?

Get an instant quote in 10 seconds through our smart system.