MES System Improves PCB Assembly Efficiency and Quality Control

In OEM and ODM projects, PCB board fabrication and PCB assembly manufacturing involve highly complex, multi-stage manufacturing processes. Their production flow encompasses multiple stages, including screen printing, SMT, DIP, soldering, testing, and assembly. Errors in any circuit board manufacturing process can lead to rework or even scrap, directly impacting costs and customer trust. Traditional management models rely on manual records and verbal communication, resulting in information silos, data lag, and difficulties in traceability. Printed circuit board assembly manufacturers face increasing pressure regarding delivery times, quality consistency, and process traceability.

MES systems are specifically designed for electronic manufacturing execution, combining order-driven workflows with real-time production visualization. By connecting personnel, equipment, materials, and environmental data to a single platform, they ensure production transparency, quality traceability, and improved efficiency in PCB manufacturing assembly execution.

1. MES System Management in Printed Circuit Board Assembly Manufacturing

(1) Production Transparency

The MES system collects real-time data on equipment, personnel, and materials, allowing management to monitor order progress, equipment status, and yield rates at any time without requiring multiple layers of inquiry, achieving full-process visibility.

(2) End-to-End Quality Traceability

In the event of a quality issue, the MES system can track the entire process via barcodes/RFID, quickly locating the specific batch of raw materials, production equipment, operator, and time point. It supports both forward and reverse traceability, shortening troubleshooting time and meeting customer audit requirements. This is especially important for high-reliability fields such as medical and automotive industries.

(3) Reduce Human Error

The system automatically compares the material list with the BOM to prevent incorrect or missing materials. It integrates AOI and SPI inspection equipment to monitor key parameters in real-time and issue alarms, thereby avoiding batch SMT material loading errors.

(4) Optimize Resource Scheduling

After receiving the ERP plan, the MES breaks it down into workshop-level work instructions, coordinating human, machine, material, method, and environmental resources to reduce changeover time and improve overall equipment efficiency.

(5) Standardize Operations

All work instructions and process parameters are electronically pushed to the workstation terminals to ensure consistent operating procedures and avoid misoperation caused by inconsistent versions of paper documents.

2. MES for PCB, SMT, and PCBA: One Order-Driven Manufacturing Core

SCSPCBA’s MES system integrates circuit board manufacturing, SMT line execution, and PCB assembly into a unified production logic:

- Order-based scheduling and dispatch

- Real-time work order status tracking

- Process route visibility from PCB → SMT → DIP → Test → QA

- Live yield, completion rate, and WIP control

This closed-loop execution model significantly reduces manual handoffs, data latency, and production blind spots, making it ideal for high-mix, low-to-mid volume OEM/ODM PCB assembly.

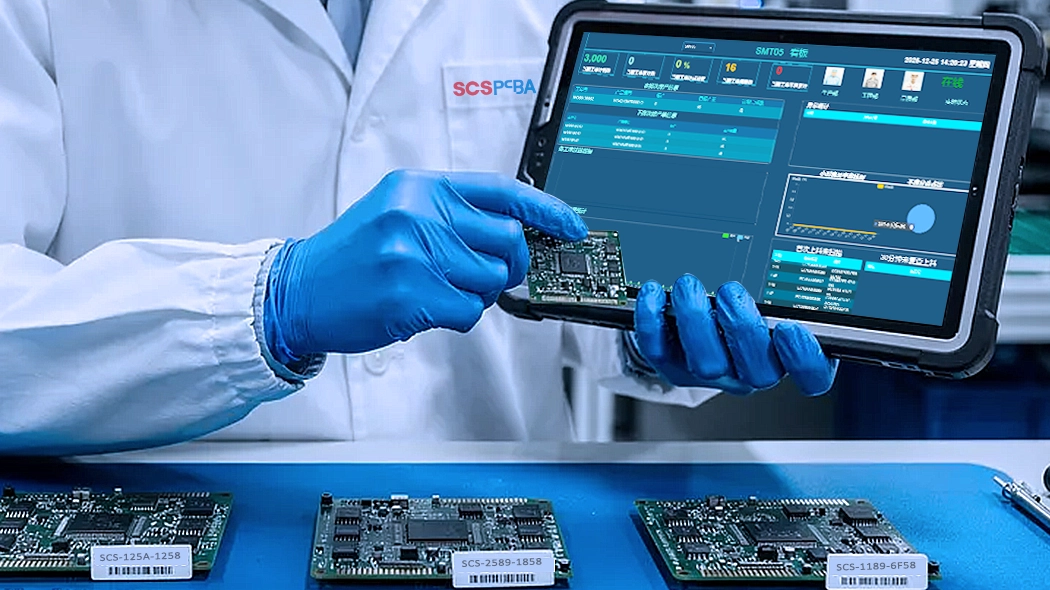

3. Real-time MES Control Panel for SMT Production Line

In surface mount technology manufacturing, PCBAs (Printed Circuit Board Assemblies) consist of thousands of micro-components, and even slight errors can lead to quality defects or functional failures. Therefore, achieving full traceability from raw materials to finished products is crucial for ensuring quality, quickly locating problems, and meeting customer audit requirements.

SCSPCBA’s MES control panel provides real-time visualization of the SMT production line’s execution status, including:

- Current work order quantity and completion rate

- Production line balancing and workstation deviation alarms

- Defect accumulation and hourly yield trend

- Online status of engineering, production, and quality departments

SCSPCBA’s MES control panel provides traceability for SMT production:

- Unique Identifier Management

Each PCB board, each work order, and each reel of materials is assigned a unique barcode or serial number. For example, during SMT production, scanning the PCB barcode binds all production data for that batch. - Error-proof loading and material association

The operator scans the material tray barcode and compares it with the Feeder position. The system automatically verifies whether it matches the BOM and station location table to prevent incorrect material loading; at the same time, it records “which tray of material is used in which SMT work order”. - Automatic data collection during production

Deploy barcode scanning equipment or interfaces at key workstations, such as printing, surface mount, reflow soldering, and AOI, to automatically collect product station information, equipment parameters (including temperature profiles), process versions, and other relevant details, ensuring that every step is traceable. - Two-way traceability capability

Forward traceability: Starting from a batch of raw materials, trace all PCBA batches produced from it and their flow.

Reverse traceability: Starting from a defective product serial number, trace back the batch of materials used, production equipment, operators, environmental parameters, etc.

For OEM PCB assembly projects, this transparency allows for immediate decision-making when deviations occur, thereby preventing small anomalies from escalating into delivery delays or batch quality risks.

4. MES System Tracks PCB/SMT/PCBA Order Progress

SCSPCBA’s MES system provides real-time order progress tracking for printed circuit manufacturing, SMT assembly, and final PCB assembly on a unified platform. Instead of providing isolated process reports, the MES system integrates order initiation numbers, completion numbers, and completion rates for each manufacturing stage, enabling the production team to continuously track the execution status from PCB to finished PCBA.

(1) Real-time Data Acquisition

For each valid order, the MES system dynamically updates the process route: drilling, electroplating, solder mask, SMT placement, AOI, DIP, testing, and QA.

- This includes placement speed, component identification accuracy, temperature profiles, etc.

- The usage path of each batch of materials is recorded via barcodes.

- Operators scan the barcodes at their workstations to report work, and the system automatically updates the progress.

This real-time monitoring enables early detection of bottlenecks, capacity imbalances, or schedule deviations, allowing for corrective actions before delivery risks occur. By transforming execution data into actionable production intelligence, the MES system ensures predictable delivery cycles, controllable work-in-process levels, and transparent delivery performance for OEM and ODM PCB manufacturing and assembly projects.

(2) Real-time Anomaly Warning and Traceability

When the following situations occur:

- Equipment malfunction

- Material shortage

- Quality issues

The system automatically triggers an alert, and through reverse tracing via the MES system, it quickly locates the specific process, equipment, operator, and even the batch of materials used, greatly shortening the problem response time.

(3) Building Long-Term Customer Trust

Real-time monitoring of PCB/SMT/PCBA order progress enables:

- Accurate delivery forecasting

- Cross-process bottleneck identification

- Transparent progress reporting for OEM/ODM customers

This data-driven execution control improves on-time delivery (OTD) rates and builds long-term customer trust.

5. Intelligent ESD & Temperature/Humidity Monitoring System

One of the most significant features of the SCSPCBA MES system is its deep integration of electrostatic discharge (ESD) protection and intelligent temperature and humidity monitoring.

The system continuously monitors:

(1)Real-time Data Acquisition and Linked Control

Temperature and humidity sensors, workstation grounding status, and equipment ESD status are connected to the network wirelessly or via wired connections. Data is uploaded to the monitoring platform in real time and integrated with the MES system. When environmental parameters exceed limits, the system automatically triggers alarms and links air conditioners, dehumidifiers, ionizers, and other equipment to adjust accordingly.

(2)Personnel Access and Process Error Prevention

Before entering the ESD protection area, employees must pass through an anti-static gate to test the grounding status of their wrist straps and shoes. The results are fed back to the MES system in real time. Those who do not meet the requirements are prohibited from entering, preventing the introduction of ESD risks into the production area.

(3)Quality Traceability and Compliance Audit

All environmental data, operation records, and alarm logs are completely stored.

Any anomalies trigger real-time alerts and traceable logs, enabling proactive quality risk prevention rather than reactive analysis.

This is crucial for PCB assembly quality:

- Preventing component damage caused by potential electrostatic discharge (ESD)

- Ensuring the entire production process complies with IPC and ESD standards

- Creating environmental traceability for quality audits

This level of environmental control is essential for high-reliability PCBAs used in industrial, automotive, and medical electronics applications.

6.Why OEM/ODM Customers Choose MES Systems

By embedding MES into daily operational processes, SCSPCBA transforms circuit board assembly services from experience-driven manufacturing to data-driven intelligent manufacturing, providing OEM and ODM customers with the following benefits:

(1) Improved Production Efficiency and Resource Utilization

The MES system optimizes production processes through automatic scheduling, real-time monitoring, and intelligent dispatching, reducing waiting time and bottlenecks. For the complex process flows in the circuit board assembly industry, MES ensures seamless connection between workstations, improving equipment and manpower utilization.

(2) Full-Process Quality Traceability and Control

This is one of the most critical value points in PCB assembly manufacturing. The MES system records a complete history from raw material warehousing, processing parameters for each process, operators, equipment status to finished product shipment. In the event of a quality problem, the source can be located within minutes, supporting rapid rectification and customer response.

(3) Supports Flexible and Rapid Market Response

Faced with frequently changing order demands, MES can dynamically adjust production plans, support mixed-model production lines, shorten changeover time, and enhance the company’s adaptability to the market.

(4) Reduces Operating Costs and Waste

Through precise material management (such as BOM control and error-proofing), control and energy consumption monitoring, MES effectively reduces raw material waste, rework, and inventory backlog, directly reducing unit production costs.

(5) Meets Compliance and Customer Audit Requirements

Many industries (such as automotive, medical, and industrial control) require stringent ISO or IATF certifications. MES provides standardized data logging and report output to help printed circuit board assembly manufacturers monitor circuit board quality.

7. FAQ

(1) What is an MES system in PCB assembly?

An MES system controls and monitors production execution in real time, covering work orders, processes, quality, and traceability.

(2) How does MES improve PCB assembly quality?

By tracking process data, defects, ESD status, and environmental conditions in real-time, MES prevents quality risks before failure occurs.

(3) Is MES suitable for low-volume OEM PCB projects?

Yes. Order-driven MES systems are ideal for high-mix, low-to-mid volume PCB and PCBA manufacturing.

(4) Does SCSPCBA MES support SMT and DIP processes?

Yes. The system fully supports SMT, DIP, testing, QA, and final assembly execution.

(5) Can customers access MES production data?

Customers can receive structured progress updates and traceability reports generated directly from the MES system