SMT templates and fixtures for PCB assembly : How to choose and control quality

In SMT (surface mount technology) production, SMT templates (also known as steel mesh) and various auxiliary fixtures are key tools to ensure welding quality and production efficiency. The surface mount template is used to control the amount and position of solder paste printing, while the fixture is used to fix the circuit board to prevent deformation and ensure the consistency of components during reflow soldering and testing. They may seem simple, but they greatly impact yield and production capacity.

What is an SMT template?

An SMT template, a steel mesh, is a thin precision metal plate with holes corresponding to component pads punched out by laser or chemical etching. The solder paste is evenly applied to the circuit board pads through these holes. The material of the steel mesh is usually stainless steel, which ensures both strength and good corrosion resistance. The thickness of the SMT template and the precision of the holes directly determine the uniformity of solder paste printing, thus affecting the reliability of welding.

How to choose the appropriate SMT stencil thickness?

In the surface mount technology process, the thickness of the stencil is crucial to the quality of solder paste printing and subsequent soldering effect. The commonly used stencil thickness ranges from 0.1mm to 0.2mm, which is usually determined based on the pad size, device package type and PCB assembly process.

- Due to the dense pins and extremely small pad spacing in fine-pitch BGA or QFN components, a thin steel mesh with a thickness of 0.1mm0.12 mm is selected to avoid excessive solder paste causing bridging.

- This type of steel mesh, with fine control of the tin amount, is more dependent on performing high-density PCB assembly.

- When it comes to soldering through-hole components or larger pads, when more tin filling is required, the appropriate use of a 0.15mm~0.18mm steel mesh can improve the strength of the solder joints.

In terms of materials, most SMT stencils are made of 304 or 316 stainless steel, which has excellent corrosion resistance, strength and durability.

- Laser cut SMT stencil, which has moderate cost and wide application, is also the most common type of solder paste template;

- Electroformed stencil, which is widely used in high-precision printed circuit board assembly due to its smooth hole wall and high solder paste release rate

- Nano coated stencils, which have high opening position accuracy, reduce solder paste residue, and improve release rate, are suitable for complex surface mount electronic components tasks and electronic assemblies production

A high-quality steel mesh not only improves welding quality but also effectively reduces defect rates, reduces rework and scrap costs, and has a positive impact on the entire SMT manufacturing processing flow.

How to check the quality of SMT stencils?

In the process of SMT patch and printed circuit manufacturing, a high-quality stencil must not only have good dimensional accuracy, but also meet a series of process standards:

(1) Stencil frame size

Check whether it is compatible with the automatic printing machine. The stencil frame structure must have sufficient rigidity and elasticity to ensure that the stencil is not easily deformed during high-speed printing.

(2) Stencil tension

The higher the tension, the better the mesh tension, and the more uniform the solder paste printing. Due to mesh relaxation, there will be no printing offset or uneven solder amount.

(3) Stencil appearance

Whether there are defects such as deformation, cracks, corrosion or contamination. For high-precision circuit boards, such as circuit board with BGA, each opening must be microscopically inspected to check whether the hole edges are clean and smooth and whether there are burrs or oxidation residues on the inner wall.

(4) Precise alignment inspection

Place the PCB to be mounted under the stencil and observe whether the leak hole and the pad are 100% overlapped. If there is misalignment, repeated holes or missing pad positions, it will directly affect the patch accuracy and welding quality.

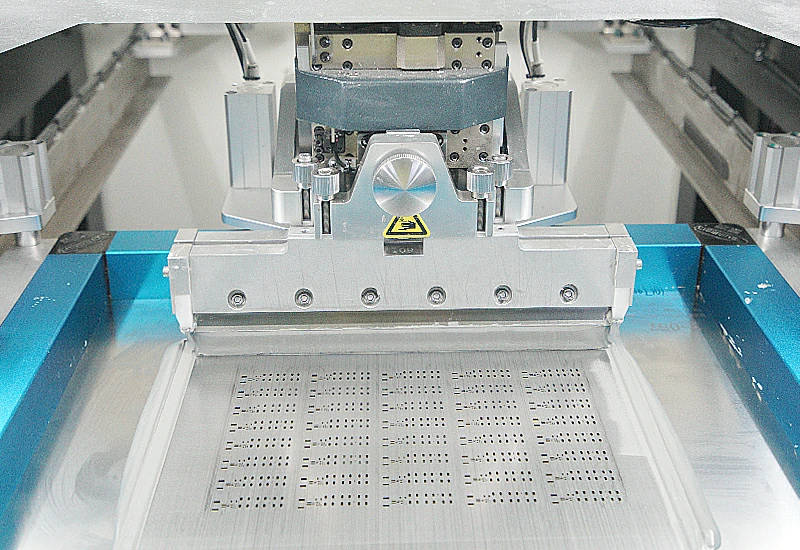

Indispensable fixture equipment in PCB assembly

In the entire process of pcb board assembly, in addition to the role of SMT steel mesh in precise solder paste printing, various auxiliary fixtures also play an irreplaceable role. These fixtures provide precision assurance, thermal deformation control and automatic adaptation support for SMT patch, DIP plug-in, reflow soldering and testing & inspection.

(1) Positioning fixture

Commonly used on patch machines to ensure stable positioning of circuit boards during the mounting process to prevent component offset or poor soldering due to slight movement. Especially in high-speed SMT mounting, accurate positioning is particularly important for PCB boards with small size or soft board material.

(2) Anti-warping support fixture

Mostly used in double-sided patch or reflow soldering. Under high-temperature reflow curve, some large-size boards or thin boards are prone to board warping, affecting the quality of solder joints. The fixture support structure can effectively alleviate thermal stress concentration, maintain PCB flatness, and improve soldering reliability. It is particularly suitable for high-density multilayer PCB and rigid-flex PCB.

(3) Functional test fixture

During the PCBA testing phase, the functional test fixture can quickly achieve the connection between the circuit board and the automated testing equipment, and is compatible with a variety of test probes or connector interfaces. It is a key tool to ensure the consistency and functional integrity of the product before it leaves the factory.

(4) Flip-board fixture

For the double-sided mounting process, a flip-board fixture is also used. This fixture has a flexible structural design and can be used to accurately flip the PCB board after one side is mounted, so that the second side can continue to be mounted and soldered. It is an important auxiliary device to improve production efficiency and accuracy.

The importance of SMT templates and fixtures to PCB Assembly

In printed circuit board production, SMT templates (stencils) and various fixtures constitute the basic guarantee tools for surface assembly processes. It is not only related to the accuracy of solder paste printing, but also directly affects the consistency of component placement, welding quality and overall production line efficiency, and is the key to achieving high-yield PCB and assembly.

The SMT stencil template is used to accurately print solder paste to the pad area, and finely control the corresponding component package size, pitch and PCB pad shape to ensure the accuracy of subsequent patching. For BGA with high-density wiring, the thickness, opening size and smoothness of the stencil are particularly critical. High-quality laser-cut stencils combined with electropolishing process can significantly improve the efficiency of solder paste release and avoid welding defects such as short circuits and bridges.

Auxiliary fixtures are widely used in multiple stages such as SMT patch, reflow soldering, THT plug-in, flip board, assembly and functional testing (FCT). For example, positioning fixtures ensure that the PCB does not shift during mounting and welding; support fixtures prevent PCB board warping or stress concentration at high temperatures, which is especially important for large-size boards or multi-layer HDI PCBs; test fixtures are used in conjunction with ICT or FCT platforms to achieve fast and efficient electrical testing.

In the process of moving towards automated assembly and lean manufacturing, the standardization and customization of templates and fixtures are particularly important. By connecting with MES system data, they can also help achieve process traceability and improve production transparency.

In summary, SMT templates and fixtures are not only the “invisible protagonists” of PCB Assembly, but also an important guarantee for improving process capabilities, reducing defect rates, and accelerating delivery cycles. A set of reasonably matched and structurally optimized fixture systems is an indispensable core capability for one-stop printed circuit board manufacturers to move towards high-end manufacturing.

Small details determine great quality

Although SMT templates and fixtures seem to be “auxiliary materials”, they play an irreplaceable role in PCB board assembly. From template thickness to fixture structural design, every detail is related to circuit board quality and scspcba PCBA manufacturer image. Only by continuously controlling template processing quality, designing fixtures on demand, and cooperating with advanced mounting technology can we support today’s stringent requirements for high density and high reliability in electronic manufacturing.