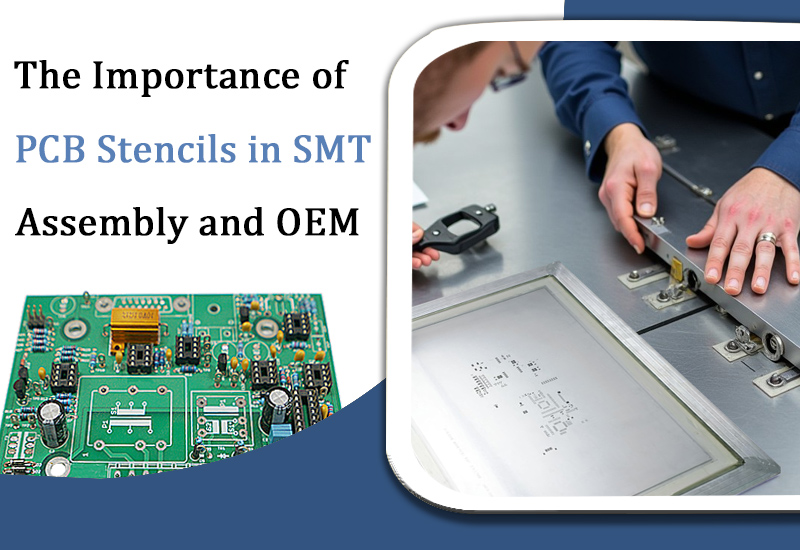

The Importance of PCB Stencils in SMT Assembly and OEM/ODM

In the SMT surface mounting technology, the printed circuit board stencil is an indispensable and important process tool in the solder paste printing process. Although the stencil is small, it plays an “invisible key role” in the precision and yield control of electronic manufacturing. Especially in the OEM (original equipment manufacturing) and ODM (original design manufacturing) service system, the stencil’s precision, production quality, and on-site management level directly affect the efficiency and quality of the entire printed circuit assembly processing.

1. The Role of The Steel Plate in Circuit Board Solder Paste Printing

Steel plate is a template for accurately printing solder paste onto PCB pads. Its surface is covered with openings designed by customers. The openings’ position, shape and size directly determine solder paste deposition. Only by achieving accurate printing on the steel plate can we ensure that the subsequent electronic components have a good welding foundation and avoid problems such as cold soldering, continuous soldering and insufficient soldering.

2. On-site Technicians Introduce The Steel Plate Production and Storage Process

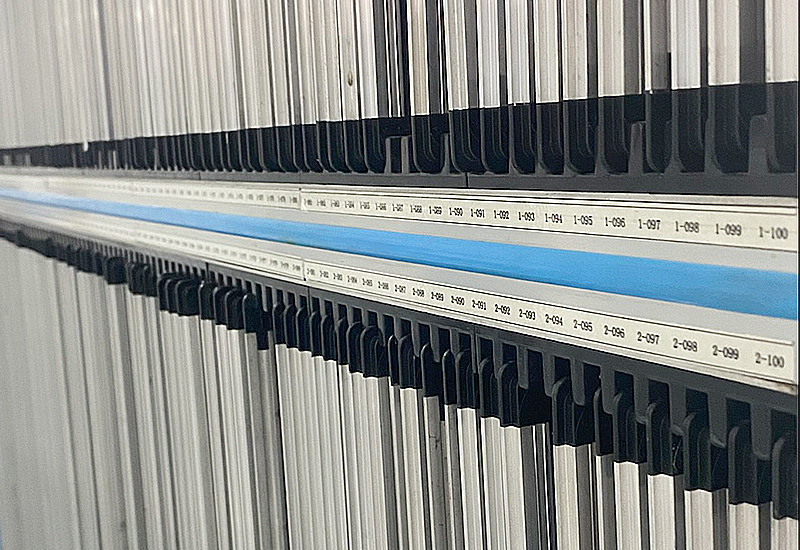

In SCSPCBA printed circuit manufacturing factory with an SMT automated production line, technicians are introducing the storage and use process of steel plates

“All our steel plates are made of 304 stainless steel and processed by high-precision laser cutting machines. After production, they are uniformly numbered and bound to customer orders for easy traceability later.” The technician introduced while operating.

The steel plate production process includes:

- Customer data import: engineers convert Gerber files into steel plate processing drawings;

- Laser drilling: Use high-speed laser cutting machines to drill holes with an accuracy of ±0.01mm;

- Deburring/cleaning: Ultrasonic cleaning and polishing are performed after drilling to ensure smooth hole walls;

- Netting shaping: The steel plate is stretched on a fixed aluminum frame to ensure that the steel plate is flat and accurately positioned;

- Warehouse management: The finished steel plates are entered into the system and stored on classified racks.

All steel plates are suspended vertically and classified by number to ensure moisture-proof, anti-bending, and anti-scratch

To prevent the deformation and oxidation of the steel plates from affecting the printing quality, the temperature and humidity of the printed circuit assembly factory workshop are monitored all day, and regular cleaning and inspections are arranged to ensure that each steel plate is always in the best condition.

3. Application of Steel Plates in OEM/ODM Projects

The accuracy of steel plates is not only the basis for quality assurance, but also the key to the efficient implementation of OEM/ODM projects.

In OEM production:

The customer provides complete design documents, and the steel plate must completely match the customer’s pad design. Any size deviation may cause poor solder joints. Accurately making steel plates helps to ensure printed circuit board manufacturing process quality and improve customer satisfaction.

In ODM projects:

SCSPCBA not only designs PCB circuit board structures on behalf of customers, but also optimizes the shape of steel plate openings, such as honeycomb and long ellipse, in combination with component layout, to improve solder paste release and wetting effect, and reduce defective rates.

In addition, by connecting steel plate numbers with the MES system, project switching and quality traceability can be quickly realized, the efficiency of line changeover can be improved, and flexible circuit board manufacturing capabilities can be greatly enhanced.

4. Paying Attention to Every Steel Plate Is To Guard Every Quality Line of Defense

Although the steel plate does not appear directly in the terminal printed circuit board assembly, it is a prerequisite for achieving high-quality PCBA assembly. In the highly automated and refined OEM/ODM manufacturing environment, professional control of the production, management, and use process of steel plates is one of the core competitiveness of PCB board manufacturers that stand out in the market.

Only by paying attention to details can SCSPCBA achieve high-quality, high-efficiency, and high-reliability PCB assembly and manufacturing delivery in the global electronic manufacturing industry chain.