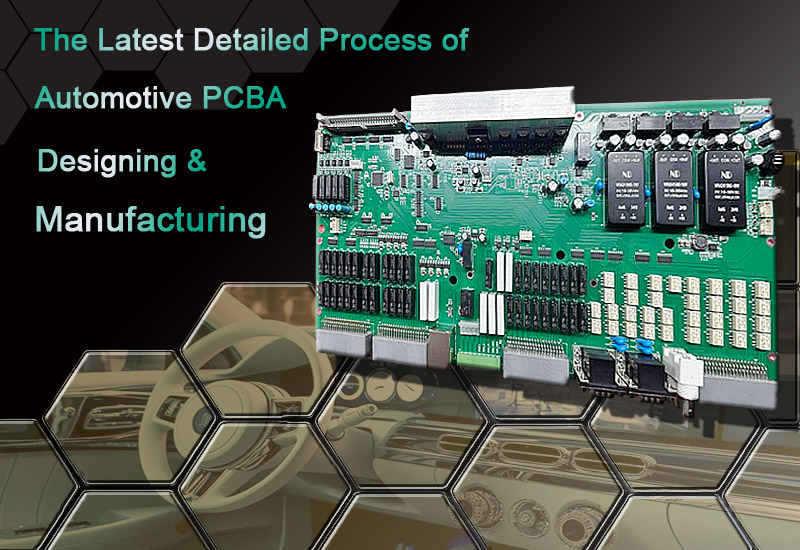

The Latest Detailed Process of Automotive PCBA Designing and Manufacturing

Automotive circuit board assembly is carefully designed and manufactured to ensure its perfect operation. PCB fabrication manufacturers should consider various factors to ensure high-quality, reliable, strong, and durable car circuit boards.

1. Create PCB Principle Diagram Design

Creating a schematic design is the first step in the automotive circuit board design and manufacturing process. In this process, since auto electronic design and manufacturing involve a lot of information, the specific information includes the application of automotive electronics, the type of onboard electronic system, the type of PCB, the number of layers, the size, and the materials of components used. All information for manufacturing automotive electronics PCBA must be accurate to be used in the initial design and manufacture of automotive electronic circuit boards.

2. Review the BOM List

Review the BOM for the design and manufacture of automotive PCB assembly. Check that all listed components are consistent with the schematic and design specifications. Ensure that all components are listed and not missing. Identify if there are acceptable alternative components and indicate them in the BOM. This will provide a backup plan in case of problems in the supply chain. By uploading BOM file, you can ensure the correctness and availability of all components and materials, guaranteeing smooth manufacture and automotive PCB assembly.

3. Electronic Component Selection

After the schematic design, component selection according to the circuit board design requirements is an important step in designing automotive PCBA boards. Select appropriate electronic components and confirm the availability and compatibility of car circuit boards, vehicle-mounted electronic PCB board fabrication, and vehicle-mounted PCBA manufacturing.

Since in-vehicle PCBA products usually need to meet the requirements of high reliability and long life, PCB board parts that can withstand the automotive working environment, such as high temperature, low temperature, humidity, vibration, etc., are selected, and the specification parameters of each component, such as voltage, current, power, package type, etc., are checked, especially for components with high-reliability requirements for automotive electronic systems. At the same time, components that meet automotive electronics industry standards, such as AEC-Q100, AEC-Q200, etc., should also be selected to ensure the reliability and safety of components in automotive applications.

4. Automotive Printed Circuit Board Classification

● Single-sided Circuit Board

The most basic PCB, with components concentrated on one side and wires relatively concentrated on the other side. Mainly used in simple automotive control units, vehicle-mounted electronic systems and other low-cost circuit boards.

● Double-layer PCB Board

There are wiring on both sides of the substrate, and there is an appropriate circuit connection between the two sides. The circuits on the upper and lower sides are connected through vias, which can be used for more complex circuits

● Multilayer Printed Circuit Board

It is composed of three or more conductive layers, and the layers are connected through inner layer vias. It is suitable for high-density and complex electronic systems, such as the central control system and advanced driver assistance system (ADAS) of automobiles.

● HDI PCB

HDI PCB has the characteristics of high density, fine wire, small aperture, etc. It uses micro-hole technology and fine wiring to achieve higher component density and smaller board size. It is suitable for complex in-vehicle electronic devices such as in-vehicle displays and navigation systems.

● Heavy Copper PCB

Any circuit board with a copper layer thickness of 30z or above can carry large current and high voltage and has good heat dissipation. The power management system of the car and the battery management system of the electric car usually use heavy copper PCB.

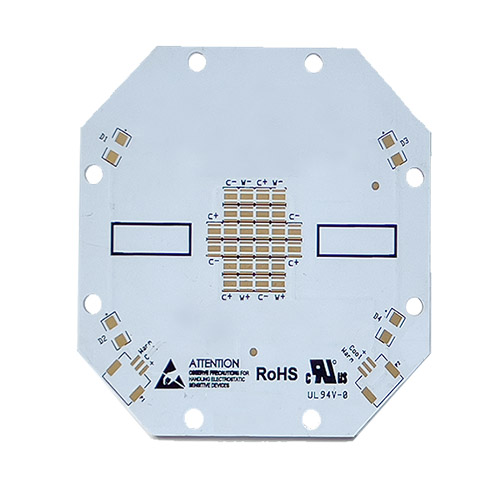

● Metal Base PCB

The composite printed circuit board consists of three parts: metal substrate, insulating dielectric layer and circuit layer. It has the characteristics of good heat dissipation and good machining performance. It is suitable for other automotive power applications such as on-board LED lighting, car headlights, car light control systems, etc.

● High-frequency PCB

High-frequency PCB is designed to handle high-frequency signal transmission and is commonly used in automotive electronic systems such as radar, communication and wireless transmission.

● High-speed PCB

High-speed PCB is designed for high-speed signal transmission, ensuring signal integrity and low latency. It is commonly used in automotive infotainment systems, in-vehicle networks, and data communication systems.

5. Automobile Motherboard Printed Circuit Manufacturing

● Material Preparation

Prepare corresponding motherboard materials for different types of automotive circuit board assembly manufacturing requirements, single-sided PCB, double-layer PCB, multi-layer PCB, HDI board PCB, thick copper board PCB, metal substrate PCB, high-frequency PCB, high-speed PCB

● Graphic Transfer

Transfer the circuit design graphics to the photo-drawing film to generate the circuit pattern. Align the photo-drawing film with the PCB substrate and expose it. After development, only the required circuit graphics are retained.

● PCB Board Etching

Remove excess copper to form a circuit.

● Drilling

Drill through holes and blind holes circuit on board according to design requirements. These holes are used for interlayer connection and component pin insertion

● Surface Treatment

Electroplating treatment is performed on the PCB surface, such as tin plating, gold plating, etc., to enhance welding performance and corrosion resistance. At the same time, component identification and other markings are printed on the PCB surface to facilitate component assembly and maintenance.

6. Functional Testing

After the automotive electronic finished product assembly is manufactured, the automotive printed circuit board manufacturers conduct comprehensive functional testing to ensure that the automotive electronic PCBA board can meet the design requirements and reach the standards of high reliability and high performance.

● Electrical Testing

Test the power supply performance of the automotive electronic printed circuit board assembly under different working voltages, including power startup, voltage regulation and overcurrent protection functions, to ensure the integrity and stability of the signal

● Functional Testing

Perform functional testing on the automotive control board PCB Assembly to ensure that each control function works properly, including engine control, body electronic control, etc. Test the communication interface between the PCBA and other on-board electronic equipment, such as LIN bus, Ethernet, etc., to ensure the correctness and reliability of data transmission.

● Environmental Simulation Testing

Place the pcb circuit board in a high and low-temperature cycle environment to test its performance and reliability under extreme temperatures. Simulate the vibration environment generated during the driving of the car to ensure that the PCBA can work normally under the vibration environment.

● Troubleshooting and Repair

Repair the faulty PCBA and retest it to ensure the problem is solved.

7. Packaging and Delivery of Vehicle-mounted Printed Circuit Assembly

After the automotive PCBA products pass the functional test, the qualified PCB products are cleaned, packaged, and ready to be delivered to customers.

Use different packaging materials, such as anti-static packaging bags to package PCBA products to avoid static damage to products; you can also use foam, bubble pads and other shockproof materials to ensure that the PCBA is not physically impacted during transportation.

SCSPCBA not only has professional PCBA manufacturing capabilities but also has a strict delivery process, confirming order information with customers, including product quantity, specifications, delivery address, etc., to ensure that there are no errors. Through the tracking system of the logistics company, the transportation status is monitored in real-time, and the customer is notified of the dynamics of the goods promptly. As a professional automotive circuit board manufacturer, SCSPCBA provides necessary technical support and after-sales service to deal with problems encountered by customers during use.