Professional Automotive PCB Assembly Services for Reliable Vehicle Electronics

At SCSPCBA, we understand the zero-compromise demand for safety and reliability in automotive electronics. As an IATF 16949:2016 certified manufacturer, we provide end-to-end, high-reliability PCB assembly services from prototype to production. Our solutions power critical systems like ADAS, powertrain, and in-vehicle infotainment, ensuring peak performance in the most demanding environments.

What is Automotive PCB Assembly?

Automotive PCB assembly refers to the process of assembling printed circuit boards specifically designed for vehicle electronics. These PCBs must meet stringent requirements for heat resistance, vibration tolerance, and long-term durability. Applications range from engine control units and battery management systems to infotainment and ADAS (Advanced Driver Assistance Systems).

PCBA Manufacturing Process Tailored for Automotive Demands

At SCSPCBA, we utilize a smart, ISO/IATF-certified PCBA manufacturing process that supports:

- Surface Mount PCB Assembly (SMT) with automated placement and AOI inspection

- Through-Hole Assembly for high-power components

- X-ray and ICT Testing for quality assurance

- Environmental Reliability Testing for vibration, temperature, and humidity performance

Our facilities support rapid prototyping and mass production for both low- and high-volume automotive applications.

Key Features: From Surface Mount to Full Turnkey PCB Assembly

We offer a one-stop, full turnkey PCB assembly service tailored for the automotive sector:

- BOM analysis and component sourcing

- SMT, THT, and mixed-technology assembly

- Functional and reliability testing

- Customized packaging and delivery

All assemblies are produced with automotive-grade materials and processes, ensuring compliance with global standards such as IPC-A-610 Class 3 and AEC-Q200.

Why Automotive Brands Trust SCSPCBA

With over 20 years of industry experience and factories in Shenzhen, Jiangxi, Vietnam, and Jiangsu, SCSPCBA is a trusted partner for global automotive OEMs and Tier 1 suppliers. Our engineering team ensures DFM optimization, cost control, and consistent quality from prototype to full production.

Key advantages include:

- IATF 16949 certified lines for automotive PCB assembly

- In-house testing and quality traceability

- Fast lead times and real-time order tracking

- Bilingual engineering support and on-demand consultation

Our Quality Commitment: Beyond Standard Automotive PCB Assembly

We are an extension of your quality team. Our “zero-defect” mindset is built into every step of our process, guaranteed by a system designed for the automotive industry. Choosing a reliable PCBA supplier is vital to product safety and performance. SCSPCBA provides design review, component alternatives, and DFX analysis to reduce printed circuit board production failure rates and shorten development cycles.

☞ SCSPCBA’s Automotive Assembly Capabilities

- SCSPCBA offers comprehensive automotive PCB assembly solutions tailored for today’s evolving vehicle technologies. Our manufacturing capabilities are built to handle the most demanding automotive electronics, supporting both high-reliability requirements and large-scale production needs.

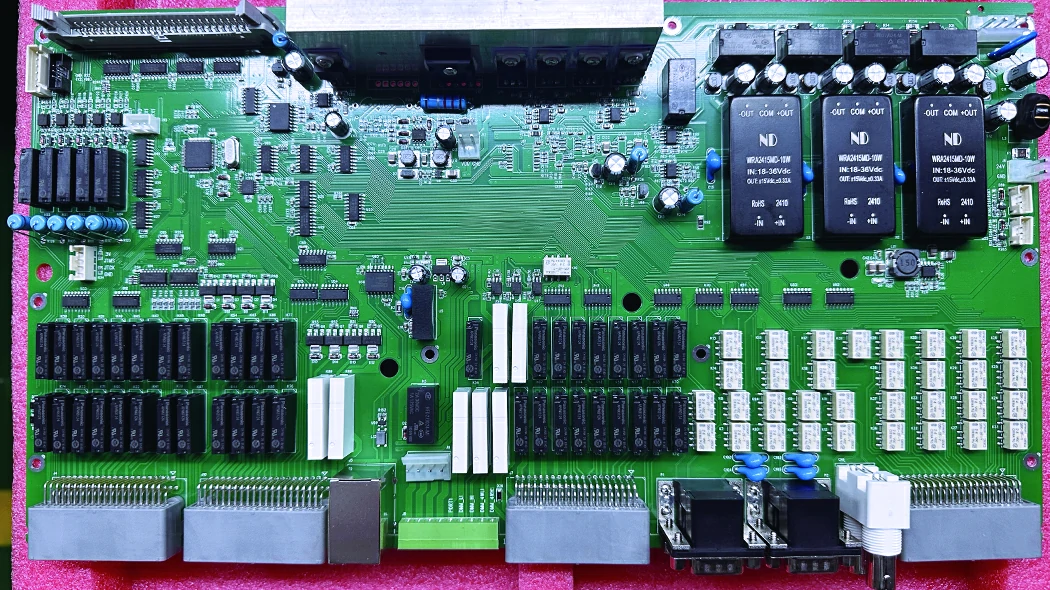

☞ Advanced Assembly Technologies

- Precision SMT assembly for high-density automotive circuits

- Selective wave soldering and through-hole technology for power electronics

- Automated optical inspection (AOI), X-ray, and functional test systems

☞ Automotive-Grade Standards

- Full circuit board material traceability and serial number tracking per automotive requirements

- IATF 16949:2016 Certified Quality Management System

Every process, from design review to final delivery, adheres to the global standard for automotive production, ensuring full traceability and continuous improvement. - IPC-A-610 Workmanship Standard

Our assembly and inspection criteria meet the highest acceptance standards for dedicated service electronic equipment, as defined by the IPC.

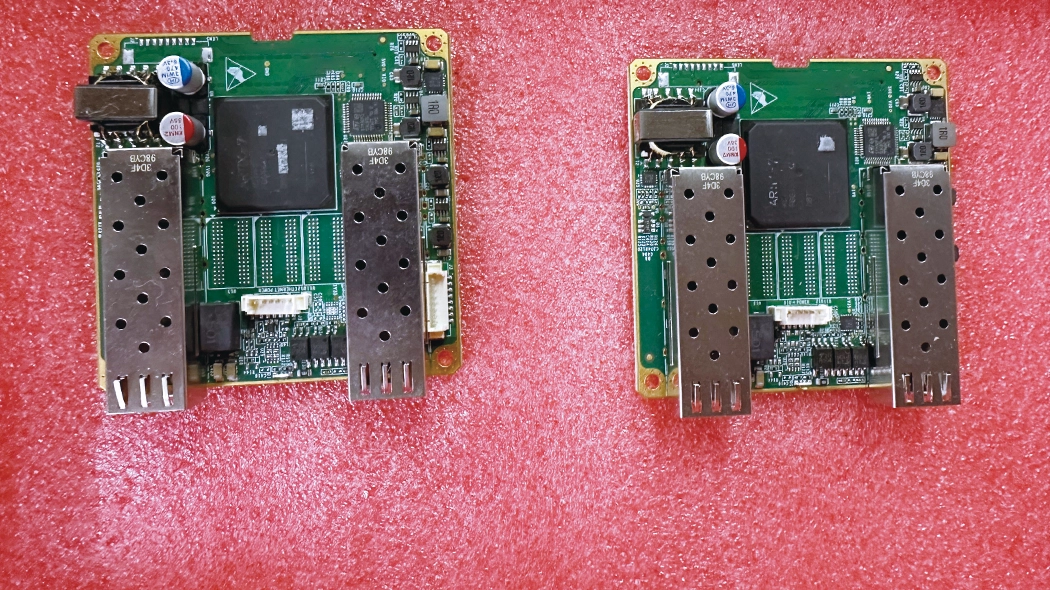

☞ Automotive-Grade Component Sourcing & Management

- We partner with franchised distributors to source 100% certified AEC-Q100/Q101 components, providing full supply chain traceability and counterfeit component prevention.

☞ Application Expertise

- EV battery management systems (BMS)

- Motor control units, ECUs, and smart inverters

- Infotainment systems, HUDs, and sensor control modules

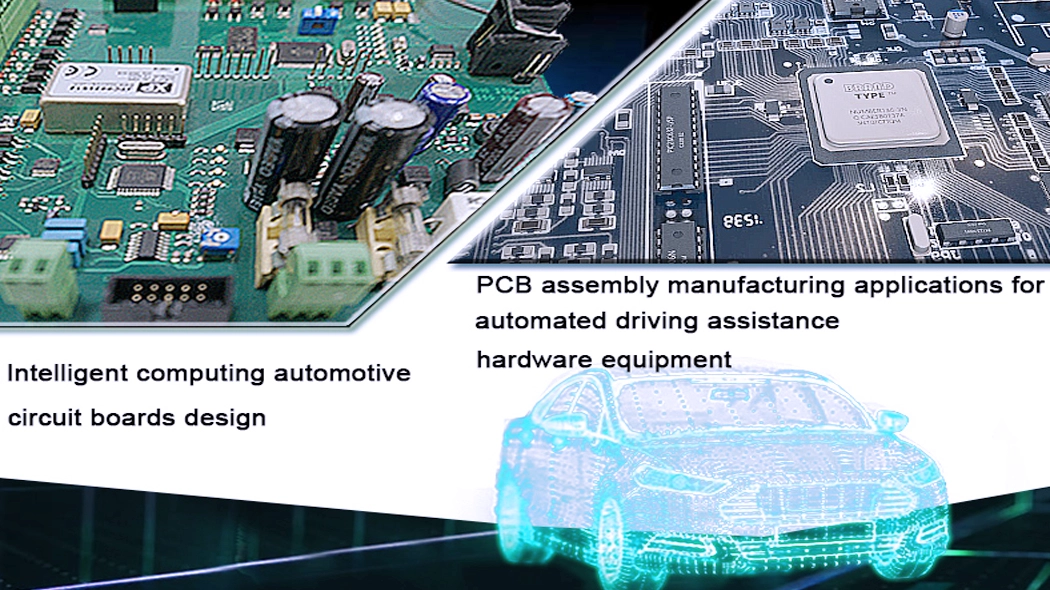

- Advanced Driver Assistance Systems (ADAS)

☞ Integrated Services for Automotive Clients

- Engineering support for DFM/DFX optimization

- Fast printed circuit board prototyping and scalable volume production

- Bilingual project management and flexible logistics

With over 20 years of experience serving Tier 1 automotive suppliers and EV innovators, SCSPCBA ensures the performance, durability, and scalability your automotive projects demand.

☞ Comprehensive Test Strategy

Our multi-stage inspection firewall eliminates defects:

- Automated Optical Inspection (AOI): 100% board coverage for post-reflow solder defects.

- X-Ray Inspection (AXI): For voiding analysis and hidden solder joint inspection (BGA, QFN).

- In-Circuit Test (ICT) / Flying Probe Test: Verifies netlist connectivity and component values.

- Functional Test (FCT): Simulates the real operating environment to validate full system performance.

- Environmental Stress Screening (ESS): Burn-in and thermal cycling to identify early-life failures.

Your project deserves a manufacturing partner with the highest standards.

Whether you’re in the prototype stage or need mass production support, our automotive electronics experts are ready to provide technical support and design for manufacturability (DFM) analysis.

SCSPCBA Serves Core Automotive Electronics Applications.

We deeply understand the unique requirements of each automotive electronics system and provide customized printed circuit assembly solutions.

☞ ADAS (Advanced Driver Assistance Systems)

- Challenges: Zero failure rate requirements, high-speed data processing, and extreme environmental conditions.

- Our approach: High-performance, automotive-grade components; stringent signal integrity control; and comprehensive functional testing and environmental stress screening (ESS).

☞ Powertrain and Engine Management

- Challenges: Continuous exposure to high temperatures, severe vibration, and chemically aggressive environments.

- Our solutions: Utilizing high-temperature-resistant materials (such as HTg PCBs); enhanced mechanical attachment processes; and applying an IPC-7091-compliant underfill to protect BGA components.

☞ In-Vehicle Infotainment System

- Challenge: Highly integrated, integrating multiple complex functions (audio, video, navigation, connectivity).

- Our Solution: Expertise in high-density interconnect (HDI) board design and manufacturing; extensive experience in flexible printed circuit (FPC) and rigid-flex board assembly; and stringent EMC/EMI control.

☞ Body and Comfort Systems (BCM, lighting control, seat control, etc.)

- Challenges: High cost-effectiveness, stability in mass production, and diverse communication protocols (LIN, CAN, etc.).

- Our solution: Optimizing the supply chain to provide highly competitive costs; efficient mass production capabilities; and stable product quality control.

Our Automotive PCB Assembly Process

SCSPCBA meticulous, transparent, and controlled manufacturing workflow guarantees your project success.

-

Design for Excellence (DFM/DFA Analysis): We analyze your design files and provide a report to optimize for manufacturability, cost, and reliability.

-

Controlled Material Procurement: Secure sourcing of all automotive-grade components with full documentation.

-

Precision SMT & THT Assembly: State-of-the-art automated lines with closed-loop process control.

-

In-Line Inspection: Real-time quality checks with AOI and SPI (Solder Paste Inspection).

-

Conformal Coating: Precision application of protective coatings for humidity and contamination resistance.

-

Full Validation Testing: Execution of ICT, FCT, and other required tests.

-

Safe Packaging & Logistics: ESD-safe, moisture-sensitive, and robust packaging for secure shipping.

Request a BOM Quote

Ready to start your automotive PCB assembly project?

Please provide your project requirements, and we’ll provide you with a detailed quote within 24 hours.

Upload your Gerber file and BOM list, and our team will respond within 24 hours with a detailed quotation.

Learn More About Our Turnkey PCB Assembly Services

From prototypes to full production, SCSPCBA delivers efficient, scalable, and reliable assembly solutions that meet the demands of the automotive industry.