Automotive PCB Assembly: Standards, Trends, and How to Choose the Right Partner

As the global automotive industry transforms towards electrification, intelligentization, and connectivity (the “three modernizations”), automotive PCB assembly has become a fundamental technology in modern automobiles, supporting various aspects such as powertrain control, ADAS (Advanced Driver Assistance Systems), infotainment systems, and vehicle electronics. It also drives a comprehensive upgrade in materials, processes, and equipment for automotive PCB assembly.

We will help engineers and procurement teams practically evaluate key factors when seeking automotive PCB assembly partners.

1. Technological Development of Automotive PCB Assembly

(1)Upgrading to High-End HDI, Multilayer Boards, and High-Frequency High-Speed Boards

To meet the high bandwidth and low latency requirements of autonomous driving sensors (such as millimeter-wave radar), vehicle communication modules, and AI chips, PCB assembly for automotive needs to have stronger signal transmission capabilities. Therefore, traditional PCBs with fewer than 6 layers are gradually being replaced by high-end HDI, ultra-high-layer circuit boards, and high-frequency high-speed boards. These high-end boards can support more refined circuit design and higher-frequency signal processing, and are widely used in intelligent vehicles.

(2)Material Innovation

Traditional FR-4 epoxy resin + glass cloth materials are no longer sufficient to meet the requirements of high-frequency signal transmission. Automotive PCB materials are increasingly utilizing materials with a low dielectric constant and low loss factor, such as PTFE (polytetrafluoroethylene), to minimize signal distortion and interference, thereby enhancing communication stability. This trend is particularly evident in ADAS (Advanced Driver Assistance Systems) and V2X (Vehicle-to-Everything) scenarios.

(3) Embedded Packaging

Emerging chip-embedded PCB packaging technology directly embeds power chips inside the PCB substrate, achieving integrated optimization of electrical connections, heat dissipation paths, and mechanical structures. This technology not only reduces module size but also improves thermal management and system reliability, and has already been mass-produced and applied in some electric vehicle inverters.

(4)Reliable automotive PCBA supplier

Automotive electronic assembly suppliers are increasingly adopting high-precision equipment, such as chip mounters, combined with AOI (Automated Optical Inspection) vision inspection systems, to improve production efficiency and yield rates. Simultaneously, automotive PCBA suppliers are building smart factories to achieve end-to-end digital management from order to delivery.

Multilayer Printed Circuit Boards Inside Vehicles – Powertrain, ADAS Modules, and Control Units

2. Challenges Facing Automotive Printed Circuit Board Assembly

Automotive electronic systems differ from consumer or industrial equipment; they are directly related to driving safety and life safety. Therefore, they face higher levels of challenges in circuit design, PCB material selection, circuit board manufacturing processes, and testing and inspection. Especially against the backdrop of the rapid development of new energy vehicles, PCB assembly for automotive electronics must operate stably for extended periods in harsh environments such as high temperature, vibration, and humidity.

Key Challenges:

(1) Strong Environmental Adaptability

Automotive electronics PCBs operate in temperatures ranging from -40°C to 125°C+ (up to 150°C in some areas), requiring them to withstand extreme temperature differences, humidity, salt spray corrosion, oil erosion, and continuous mechanical vibration. This places higher demands on material selection (e.g., using high Tg substrates), structural design, and packaging processes.

(2) High PCB Routing Density

Modern automobiles integrate numerous sensors, controllers, and communication modules, resulting in highly dense PCB wiring. Simultaneously, power devices (such as IGBTs and SiC/GaN) generate significant heat, necessitating efficient heat dissipation using metal-based copper-clad laminates (e.g., aluminum-based or copper-based).

(3)High-precision and High-reliability Assembly Processes

ADAS system circuit boards often use tiny components (such as 0201 packages) and rely on precision processes such as SMT placement, reflow soldering, and AOI inspection. Any soldering defects can lead to system failure, therefore, full automation and multiple quality inspections are required.

(4)High Electromagnetic Compatibility (EMC) Pressure

Vehicles contain various high-frequency signals (radar, 5G, Bluetooth), which can easily generate crosstalk. PCB design needs to optimize the layer stack-up, increase shielding ground planes, and strictly control impedance matching to ensure signal integrity and anti-interference capabilities

(5)Long-cycle Testing

The car PCB board requires rigorous functional testing, thermal cycling, and HALT high-acceleration life testing from printed circuit board design to mass production, with a cycle lasting several months or even more than a year, far exceeding the few weeks of consumer electronics.

This requires Automotive PCBA manufacturers to comprehensively upgrade their materials, processes, quality systems, and functional safety, which is far beyond what is possible for consumer electronics or ordinary industrial electronics.

3. Improve the Technology for Producing High-end Automotive PCB Assembly

The low-to-mid-end automotive PCB market suffers from severe homogenization, with PCB board production concentrated on ordinary multilayer boards. Simultaneously, the price war in the new energy vehicle sector is forcing component price reductions, forcing PCB suppliers to accept 10%-15% price cuts. Small and medium-sized PCB companies are suffering losses due to the price war, with some forced to exit the market, further impacting the stability of the low-to-mid-end supply chain.

The motor control system, battery management system (BMS), and autonomous driving sensors (such as LiDAR and millimeter-wave radar) of new energy vehicles require high-frequency, high-speed, high-voltage, multilayer HDI boards, demanding extremely high signal transmission stability. For example:

- High-end PCBs must meet characteristics such as ±0.002mm accuracy and resistance to 200℃ high temperatures.

- The heat dissipation channel accuracy of silicon carbide power module substrates needs to be controlled within ±0.005mm, directly affecting motor efficiency.

However, the construction of high-end PCBA production lines takes 12-18 months, while the global monthly production capacity of core materials (such as HVLP4 grade high-frequency copper foil) is only 700 tons. Data shows that in 2025, the demand is 850 tons/month, resulting in a shortage of more than 40%.

Therefore, automotive printed circuit board assembly manufacturers need to develop high-frequency substrates (such as polytetrafluoroethylene PTFE) to reduce 5G/millimeter-wave radar signal loss; promote diamond-coated drill bits to improve processing accuracy; and simultaneously introduce AI defect detection systems to increase the yield rate of PCB assembly for automotive electronics from 70% to over 98%.

High-precision, high-reliability assembly process for automotive electronics circuit boards

4. Qualified Automotive PCB Assembly Process

(1) Substrate Pretreatment and Pad Preparation

Plasma cleaning technology is used to remove organic contaminants from the PCB surface and improve solder paste adhesion. For high-reliability products, ultrasonic cleaning is required. Substrate drying and stress relief are also important; multilayer boards require low-temperature annealing to reduce solder warpage.

(2) Solder Paste Printing Process and Parameter Optimization

Select appropriate solder paste based on pad size and soldering process. Stencil design must be reasonable, and printing parameters such as squeegee pressure and demolding speed need to be optimized. 3DSPI inspection is used for circuit board quality testing to ensure that solder paste volume deviation, height difference, and bridging defects meet standards.

(3) Component Placement Technology and Precision Control

Select appropriate placement equipment based on PCB board component type and design appropriate reference points. Placement process parameters such as nozzle selection, placement pressure, and placement accuracy must be strictly controlled to ensure placement yield.

(4) Soldering Process and Temperature Profile Optimization

Select appropriate soldering processes based on component type, such as reflow soldering or wave soldering. Temperature profiles need segmented control. For fine-pitch components, nitrogen protection can reduce oxidation and improve solder joint wettability.

(5) Follow International Certification and Industry Standards

The formulation and implementation of automotive PCB process standards are crucial to ensuring the reliability and safety of automotive electronic systems. PCB design, PCB board fabrication, installation, and AOI, X-ray, functional testing, and ICT testing must all comply with relevant international certification and industry standards, such as ISO 26262, IPC-6012, IPC-6011, IPC-A-610, and IPC-A-600.

5. Key Industry Standards and Certifications

Automotive PCB assembly suppliers are typically evaluated against the following globally recognized standards:

(1)AEC Component Compliance

While AEC standards (such as AEC-Q100 and AEC-Q200) apply to components rather than assembly, reputable assemblers must understand and verify component-level compliance during BOM validation.

(2)IATF 16949

The automotive quality management system standard, replacing ISO/TS 16949.

It emphasizes:

- Risk-based process control

- Continuous improvement

- Full traceability across production batches

(3)IPC Standards

Commonly referenced IPC standards include:

- IPC-A-610 Class 2 & Class 3 (assembly acceptability)

- IPC-2221 / 2222 (PCB design considerations)

- IPC-6012DA (automotive PCB performance)

(4)ISO 9001 & ISO 14001

Baseline requirements for quality management and environmental compliance, particularly important for EU-market suppliers.

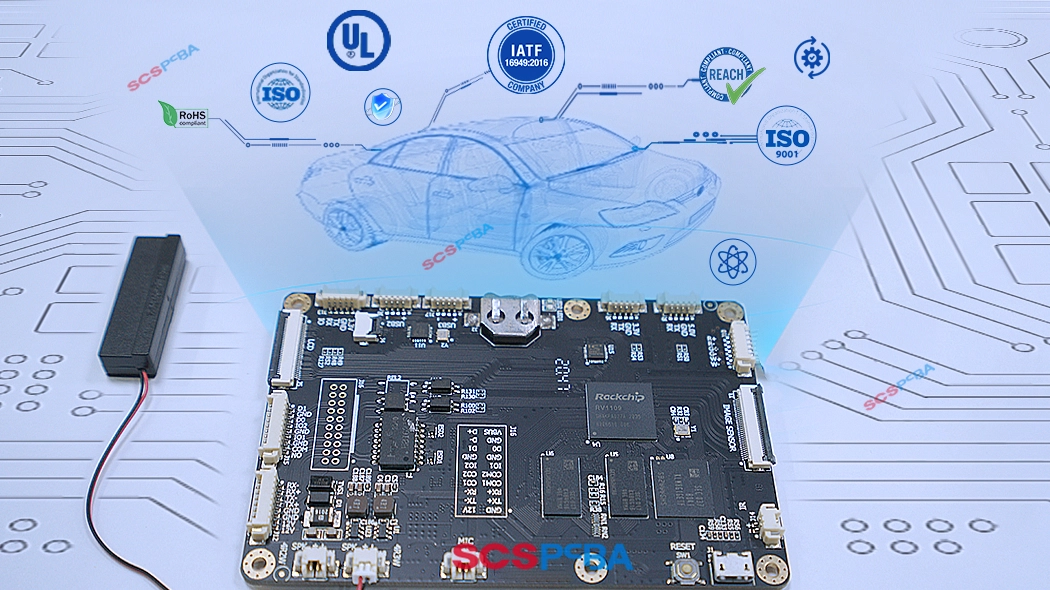

Quality control processes for automotive PCB assembly and international certifications such as ISO 9001

6. How to Select an Automotive PCB Assembly Supplier

Choosing a PCB automotive board manufacturer is a crucial decision-making process, as it directly impacts the quality and reliability of automotive electronics products. Here are some key factors to help you make an informed choice:

(1) Understand The Background of the PCB Fabrication Manufacturer

Choose manufacturers with a stable development history and a good reputation. Examine the manufacturer’s size, industry experience, customer reviews, certifications (such as IATF 16949), and partnerships. for example:

- Check if they have served well-known automakers

- Prioritize companies with automotive-grade quality management certifications to ensure they can meet your needs and provide high-quality automotive PCB boards

(2) Examining Circuit Board Manufacturing Quality

Understanding the production equipment and technology used by the manufacturer is crucial, as advanced equipment and technology are prerequisites for ensuring product quality. For example:

- Request sample test reports and conduct on-site or video audits of the PCB board production line

- Pay attention to whether automated quality inspection methods such as AOI and X-ray inspection are used

(3) Quality Control and Certification

Ensure the manufacturer has a rigorous quality control process and possesses international certifications such as ISO 9001. This is crucial for the safety and reliability of automotive electronics products.

(4) Testing Communication Efficiency

Response speed, professionalism of the technical support team, and ability to provide customized solutions. For example

- Can a quote be quickly provided after submitting the BOM?

- Is there a dedicated engineer to handle the project?

(5) Comprehensive Strength and Capabilities

Including factors such as technical support and service, production capacity, and delivery cycle. We prefer one-stop PCBA services, capable of simultaneously completing PCB manufacturing, component procurement, SMT assembly, DIP insertion, functional testing, and finished product assembly, greatly improving project progress efficiency and reducing time spent coordinating multiple stages.

(6) Cost-Effectiveness

Reasonable pricing, minimum order quantity (MOQ), and preferential terms for long-term cooperation.

When comparing quotes from multiple suppliers, it is necessary to comprehensively consider yield rate, rework costs, and hidden communication costs, rather than just looking at the unit price.

In summary, when choosing a printed circuit board assembly manufacturers for automotive applications, the above factors should be considered comprehensively, and an evaluation and selection should be made based on your specific needs. Through careful screening and in-depth investigation, you can find a reliable partner to provide high-quality PCBs for your automotive electronics products.

7. Why OEMs/ODMs Choose SCSPCBA for Automotive PCB Assembly

Choosing the right automotive PCB assembly manufacturer is not just about price, but also about long-term reliability, compliance, engineering depth, and execution efficiency. SCSPCBA is trusted by OEMs and ODMs worldwide because we deliver measurable value throughout the entire automotive electronics product lifecycle.

(1) Excellent Supplier Reputation

SCSPCBA has over a decade of experience in PCB and PCBA manufacturing, serving customers in the automotive, industrial control, and high-reliability electronics industries. We have built a strong reputation based on verified customer feedback, long-term partnerships, and international accreditations including ISO 9001, ISO 14001, and IATF 16949. Strategic partnerships with Tier 1 material suppliers and component distributors further enhance the stability and traceability of the supply chain.

(2) Automotive-Grade Manufacturing Quality

We continuously invest in advanced SMT and THT production equipment to meet the precision requirements of automotive electronics. Our factory is equipped with high-speed placement machines, nitrogen reflow ovens, and selective soldering systems. Detailed process documentation and inspection reports support the sample production process, enabling customers to conduct on-site or video audits to verify production capabilities before mass production of printed circuit boards.

(3) Strict Quality Control and Certification Compliance

SCSPCBA’s quality assurance extends throughout the entire PCBA manufacturing process. We employ automated inspection technologies, including AOI, SPI, X-ray inspection, and in-circuit testing, to detect defects such as solder joint voids, misalignments, and hidden solder joints. All processes comply with IPC-A-610 Level 2/3 standards, ensuring the reliability of automotive PCBAs under harsh conditions such as vibration, thermal cycling, and extended service life.

(4) Rapid Response Engineering and Efficient Communication

Automotive projects demand fast and accurate communication. SCSPCBA provides a professional technical support team capable of quickly responding to Bill of Materials (BOM), Design for Manufacturability (DFM) feedback, and engineering change requests. This reduces assumptions, avoids costly rework, and shortens the lead time from PCBA quotation to production—crucial for time-sensitive automotive projects.

(5) One-Stop PCBA Services

From PCB design support and material sourcing to SMT assembly, functional testing, and final product assembly, SCSPCBA offers true turnkey solutions for automotive PCB assembly. This integrated approach minimizes handover points, enhances accountability, and ensures consistent quality at every stage of production.

(6) Cost Efficiency Beyond Unit Price

We help our customers achieve sustainable cost savings by optimizing BOM structure, recommending alternative components, improving panelization efficiency, and reducing yield losses. SCSPCBA focuses not only on the lowest unit price, but also on striking a balance between quality, reliability, and long-term supply assurance.

(7) AI-Driven Intelligent Quotation System

Our proprietary AI-driven PCB, PCBA, and BOM quotation system provides fast and accurate quotes for complex automotive PCB components. By analyzing component availability, alternative sourcing, and manufacturing constraints in real time, the system reduces human error, improves quotation accuracy, and supports informed decision-making early in the project process.

Specialized equipment for the Automotive PCBA manufacturing process

8. Get Automotive PCB Assembly Quotation Quote

Durable automotive PCBA is a quality-critical, compliance-driven manufacturing discipline that directly affects vehicle reliability, safety, and lifecycle cost.

Upload your PCBA and BOM files to receive a fast, structured automotive PCB assembly quotation with full compliance review.

9. FAQ

(1) What certifications are required for automotive PCB assembly?

Most automotive projects require IATF 16949, IPC Class 2 or 3 compliance, and ISO 9001. Component compliance with AEC-Q standards is also critical.

(2) What is the difference between automotive and industrial PCB assembly?

Automotive PCB assembly involves wider temperature ranges, longer lifecycles, stricter traceability, and higher reliability requirements.

(3) Can automotive PCB assemblers support low-volume prototyping?

Yes. Many qualified suppliers support NPI and low-volume builds before scaling to mass production.

(4) How important is BOM management in automotive projects?

Extremely important. BOM inaccuracies can cause qualification failures, sourcing delays, or long