Vietnam’s Role in the Global PCBA Industry

Vietnam’s Rising Role in the Global PCBA Industry

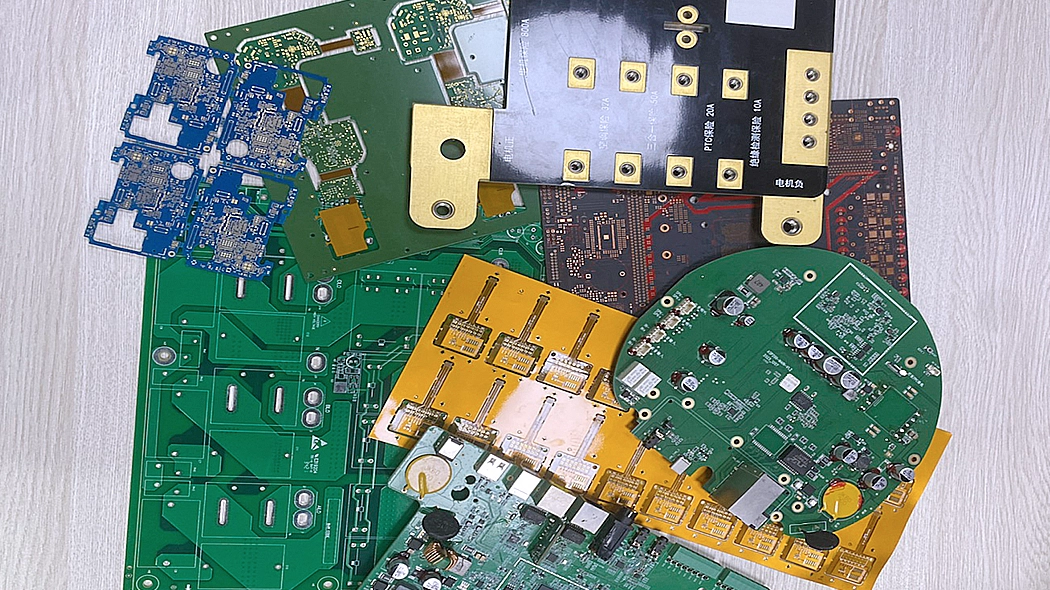

The demand for electronics manufacturing is rapidly growing worldwide, and many circuit board manufacturers are shifting their focus to Vietnam as a leading destination for PCB assembly and supply chain solutions.

With a combination of cost advantages, skilled engineers, and modern production facilities, a PCBA factory in Vietnam can deliver both prototype runs and large-scale assembly with consistent quality. The PCBA suppliers in Vietnam provide a full spectrum of services, including PCB fabrication, SMT assembly, component sourcing, functional testing, box build assembly, and turnkey solutions. This makes Vietnam not only a cost-efficient option but also a strategic hub for companies in industries such as automotive electronics, medical devices, consumer electronics, and IoT hardware.

Choosing the right PCB manufacturing and assembly factory in Vietnam reduces costs and ensures stable production capacity, reliable quality, and access to global markets.

Why Work with a PCBA Factory in Vietnam?

Vietnam has emerged as a key hub for electronics products and PCB assembly services. Partnering with a reliable PCBA supplier in Vietnam offers several advantages:

I. Strategic Location

Convenient Transportation: Central Vietnamese cities like Da Nang, with their modern international airports and ports, facilitate efficient logistics and access to global markets.

Cost-Effective Production: Vietnamese PCB manufacturing and assembly factories offer significant advantages in large-scale manufacturing and lower labor costs, attracting outsourcing needs from international brands.

II. Technological Capabilities and Industry Ecosystem

Advanced Manufacturing Infrastructure: Vietnamese PCB assembly manufacturers are equipped with state-of-the-art equipment, including YAMAHA pick-and-place machines and AOI inspection systems, supporting full-cycle services from prototyping to mass production.

Foreign Investment Cluster Effect: Investments from global giants like Samsung and Foxconn have driven the local industry upgrade, particularly in areas like AI server PCBs and optical modules.

III. Policies and Market Potential

Export-Oriented Economy: Vietnam’s electronics exports are steadily growing (reaching $72.58 billion in computer components exports in 2024), benefiting from trade agreements.

Environmental Compliance: Emphasis on environmentally friendly production, adhering to international standards.

As a major global electronics manufacturing hub, Vietnam’s printed circuits assembly corporation offer significant advantages for collaboration.

Key Advantages of SCSPCBA PCBA Suppliers in Vietnam

The key advantages of SCSPCBA’s printed circuit assembly manufacturing plant in Vietnam include the following aspects:

1. One-Stop Printed Circuit Board Assembly Manufacturers

From PCB fabrication, components sourcing, SMT & DIP assembly to testing and box build assembly, SCSPCBA’s Vietnam factory offers complete end-to-end services, reducing lead time and simplifying supplier management.

2. Advanced SMT Production Lines

Equipped with high-speed SMT machines, AOI inspection, and functional testing and inspection systems, the factory ensures precise assembly and high-quality output, even for complex multilayer and HDI boards.

3. Cost Efficiency & Flexible Capacity

Vietnam’s competitive labor and operational costs enable SCSPCBA to provide affordable yet premium PCB board assembly services. The PCB assembly factory supports both small-batch prototyping and mass production, adapting to customer needs.

4. Global-Standard Certifications

SCSPCBA’s Vietnam site follows ISO, RoHS, and IATF 16949 (for automotive electronics) standards, ensuring compliance with international quality and safety requirements.

5. Strategic Location for Global Supply Chains

Situated in Vietnam, the factory benefits from favorable trade agreements, reduced tariffs, and faster logistics to Europe, the U.S., and ASEAN markets, helping clients optimize global distribution.

6. Strong Engineering Support

A dedicated team of engineers provides DFM (Design for Manufacturability) guidance, cost optimization strategies, and component alternatives, ensuring reliable performance and lower total cost of ownership.

Comparing Vietnam with Other Printed Circuit Manufacturing Destinations

Compared to other Southeast Asian countries, Vietnam is an ideal location for assembling circuit boards. It offers advantages such as cost competitiveness, advanced SMT assembly lines, a skilled workforce, and ease of global trade. For businesses seeking reliable PCB and assembly factories or suppliers, Vietnam not only offers reasonable pricing but also high-quality products, making it an ideal choice for establishing long-term electronic manufacturing partnerships.

Comparison of Vietnam with other PCBA manufacturing locations:

- Thailand

Thailand has a mature electronics industry, but most of its factories primarily produce consumer electronics and automotive parts, rather than large-scale PCBA products. PCB board production costs are relatively stable, but the integration of the electronic component supply chain is not as strong as in Vietnam. - China

China remains the world’s largest PCB and PCBA production center, boasting unparalleled production capacity and technological expertise. However, rising labor costs, tariffs, and geopolitical uncertainties have prompted many PCB assembly factories to seek diversification. In contrast, Vietnam offers PCBA products of comparable quality to China, but at a more competitive price, with fewer trade restrictions for exports to Europe and the US. - Indonesia

Indonesia’s electronics industry is still developing. While labor costs are low, its PCB fabrication and assembly infrastructure and skilled workforce are not as robust as in Vietnam. Therefore, Indonesia is not ideal for companies requiring complex or high-reliability electronic component assembly. - Malaysia

Malaysia has extensive experience in semiconductor packaging and high-tech manufacturing, but its PCB assembly services tend to be more expensive due to higher operating costs. Vietnam offers better value for money and is therefore more suitable for small to medium-scale PCBA production.

Choosing the Right PCBA Supplier in Vietnam

When selecting a suitable PCB assembly supplier in Vietnam, consider the following factors:

1. Define Your Needs and Requirements

Before choosing a PCBA manufacturer in Vietnam, clearly define your product requirements, including circuit complexity, component types, prototype quantity, lead time, and budget. For example, semiconductor or communication equipment requires high-precision multilayer boards, and cost and delivery time are crucial.

2. Qualifications and Industry Certifications

Prioritize manufacturers with international certifications such as ISO 9001, IPC-A-610, RoHS, and IATF 16949 to ensure their quality management system meets industry standards.

3. Technical Capabilities and Equipment

Equipment Modernity: Assess whether the supplier has advanced equipment like YAMAHA pick-and-place machines and AOI inspection systems, and whether they have high-precision SMT production lines and an MES traceability system.

Process Capabilities: Manufacturers supporting complex processes like HDI and BGA packaging are better suited for high-density products.

4. Production and Emergency Response Capabilities

Production Capacity and Flexibility: Evaluate the daily production capacity and ability to handle urgent orders.

5. Cost and Supply Chain Management

Cost Transparency: Labor costs in Vietnam are lower than in China, but consider the impact of import tariffs on raw materials (e.g., 50% reduction under the CHIPS Act).

6. Quality and After-Sales Service

Quality Control: Require the PCBA manufacturer to provide inspection reports (AOI/SPI data) and a defective product handling process.

After-Sales Support: Confirm whether they offer long-term technical support, rework, and repair services.

How to Conduct an On-Site Audit of PCBA Supplier in Vietnam

An on-site visit to a PCBA factory in Vietnam can provide more accurate information than brochures or price quotes.

1. Pre-Audit Preparation

- Understand the supplier’s background: Review the company website, certifications (ISO, IATF16949, RoHS), verify their equipment list (e.g., YAMAHA pick-and-place machine, AOI inspection system), and check if their equipment matches production needs and customer feedback.

- Determine evaluation criteria: Quality standards, production capacity, cost structure, and after-sales service.

- Arrange a factory visit: Schedule a visit to the printed circuits assembly corporation in Vietnam, ensuring access to the production line, test area, and warehouse.

2. Key Focus Areas During the On-Site Visit

- Production Equipment

Check the accuracy of the pick-and-place machine (±0.03mm), solder paste thickness control of the printer (±0.02mm), reflow oven temperature profile stability, AOI inspection equipment, ICT/functional test system, and ESD protection measures. - Quality Management

Observe the incoming material inspection, printed circuit board production process control, and final quality inspection procedures. - Employee Skills

Evaluate the experience of technicians and engineers in circuit card assembly manufacturing in Vietnam, including their ability to assemble high-density or complex components, HDI/BGA packaging capabilities, and material compatibility (high-Tg, low-loss board materials). - Component Storage

Ensure that the storage environment, moisture protection measures, and traceability management of components meet standards. - Technical Capability Verification

Request sample test reports (e.g., AOI/SPI data) and reliability test results (e.g., temperature cycling, vibration test).

3. Certifications and Compliance

- Request relevant certifications such as ISO 9001, IATF 16949, RoHS, and UL.

- Confirm that the Vietnamese PCBA supplier complies with international quality and environmental standards.

4. Business Transparency

- Discuss supply chain strategy: How does the supplier source components? Do they work with authorized distributors?

- Review cost structure and lead time.

- Evaluate communication efficiency—crucial for long-term cooperation.

5. Trial Production or Sample Run

After the audit, request a small-batch production to verify their technical capabilities.

Evaluate DFM (Design for Manufacturing) feedback and their flexibility in cost optimization.

Why Vietnam Should Be Your Next PCBA Manufacturing Hub

Partnering with a PCBA factory Vietnam provides global companies with cost-effective, high-quality, and scalable electronic assembly services. With turnkey solutions, advanced technology, and strong government support, Vietnam is becoming one of the most trusted destinations for PCBA manufacturing and supply.

Choosing the right PCBA supplier in Vietnam is not just about production—it’s about building long-term reliability, efficiency, and global competitiveness.